Hatchery Management Guide for Game Bird and Small Poultry Flock Owners

Five major functions are involved in the incubation and hatching of game bird and chicken eggs. The five functions are temperature, humidity, ventilation, egg turning, and sanitation.

The major topics below are explained in detail in the text.

- Hatching Temperature

- Humidity in Incubators and Hatchers

- Ventilation

- Egg Turning

- Hatchery Sanitation

Each of the five functions is important and may individually cause havoc in your attempt to hatch eggs if one is not conducted properly. When two or more are not controlled, it may be a disaster. Keep in mind, that changing or adjusting one of these functions may affect other functions and cause them to need adjustment as well. Therefore, changes in any one function should be made gradually and all functions should be watched closely for needed readjustment.

Most of the large commercial type incubators and hatchers are run at 99oF. On the other hand, most of the smaller incubators and hatchers, like those commonly used by game bird producers, are run at 100oF.

Temperature is the easiest hatching function to regulate, provided you have a good set of controls to work with and provided you check the heating mechanism regularly. Without good, sensitive, easy-to-regulate, and dependable temperature controls, you can have low hatches, poor quality chicks, and you can sometimes lose the entire hatch. If your incubators and hatches are large enough to justify doing so, you should install a temperature sensitive alarm to warn you of the potential danger to the developing embryos.

Temperature alarms are usually constructed of two temperature sensors. One is set to activate the alarm if the temperature drops below 97 or 98oF. The other sensor is set to activate the alarm if the temperature goes above 102oF. This is a simple explanation of the temperature alarm and how it is installed, but even so, it is not all that difficult to install. If the machines are not in your home but are nearby, you may want to run a small wire (like speaker wire) from the machines to an alarm in your house so that you can monitor the machines at night also.

Incubation Periods & Incubation Operation Characteristics (Table 1)

| Item | Chicken | Turkey | Duck | Muscovy Duck | Goose | Guinea | Peafowl |

|---|---|---|---|---|---|---|---|

| Inc Period (days) |

21 | 28 | 28 | 35-37 | 28-34 | 28 | 28-30 |

| Temperature* (oF, dry-bulb) |

100 | 99 | 100 | 100 | 99 | 100 | 99 |

| Humidity (oF, wet-bulb) |

85-87 | 84-86 | 85-86 | 85-86 | 86-88 | 85-87 | 84-86 |

| No Egg Turning After |

18th day | 25th day | 25th day | 31st day | 25th day | 25th day | 25th day |

| Open Vents Additional ¼ |

10th day | 14th day | 12th day | 15th day | 1st day | 14th day | 14th day |

| Open Vents (if needed) |

18th day | 25th day | 25th day | 30th day | 25th day | 24th day | 25th day |

* For Forced-air incubators. Add 2-3oF. to the recommended temperatures if using a still-air incubator.

Incubation Periods & Incubation Operation Characteristics (Table 2)

| Item | Pheasant | Bobwhite Quail | Coturnix Quail | Chukar Partridge | Grouse | Pigeon |

|---|---|---|---|---|---|---|

| Inc Period (days) |

23-28 | 23-24 | 17 | 23-24 | 25 | 17 |

| Temperature* (oF, dry-bulb) (days) |

100 | 100 | 100 | 100 | 100 | 100 |

| Humidity (oF, wet-bulb) |

86-88 | 84-87 | 85-86 | 81-83 | 83-87 | 85-87 |

| No Egg Turning After |

21st day | 20th day | 15th day | 20th day | 22nd day | 15th day |

| Open Vents Additional ¼ |

12th day | 12th day | 8th day | 12th day | 12th day | 8th day |

| Open Vents (if needed) |

20th day | 20th day | 14th day | 20th day | 21th day | 14th day |

* For Forced-air incubators. Add 2-3oF. to the recommended temperatures if using a still-air incubator.

Temperature fluctuations for short periods of time usually do not severely affect hatchability or chick quality because the temperature inside the egg changes more slowly than the air inside the incubator. However, a consistently low temperature will result in a late hatch and decreased hatchability. The chicks may be large, soft bodied, and weak.

A consistently high temperature will result in an early hatch and decreased hatchability. The chicks may have short down (same results with low humidity) and have rough navels (not necessarily infected -- just abnormal closure). More chicks will be malformed, spraddled, weak, and small.

You do not want either, but if you have to choose one or the other, remember that high temperature is more harmful than low temperature. You can incubate eggs for three or four hours at 90oF. without killing many embryos, but a temperature of 105oF. for 30 minutes will kill many embryos. In general, the older the embryo at the time of the high temperature mishap, the greater the death loss.

Incubators can easily overheat when kept where the sun can hit them, such as in a hot, room on the west of the house or in a small building that is subject to heating up considerably during hot summer afternoons. Machines in such conditions, when set near full capacity and with improper ventilation will almost surely overheat. This statement does not imply that the incubator should not be set to full capacity; on the contrary, other factors must be considered and corrected before you can take full advantage of the incubator's capabilities.

HUMIDITY IN THE INCUBATOR AND HATCHER

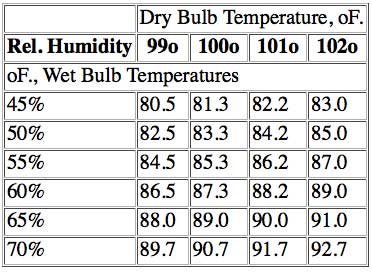

Most people think the wet bulb reading in a hatcher or incubator is percent relative humidity. This is, of course, not true. Percent relative humidity is determined by using both dry bulb and wet bulb readings. For example, if the dry bulb reading is 100oF. and the wet bulb reading is 87.3oF., the relative humidity is 60 percent. Under normal conditions the relative humidity in an incubator or hatcher should always be 57 to 60 percent. The following table gives the percent relative humidity figures for various dry and wet bulb readings.

Incubator and hatcher manufacturers offer various suggestions for dry and wet bulb settings. However, you may find by experimenting with various settings that the best way is to simply run the dry bulb at 100oF. and the wet bulb at 85 to 87oF. (Keep as near to 86oF. as possible.) Use these settings from the first day of incubation until hatching is complete.

There will be no need to vary the humidity level from 86oF. if the hatching eggs were gathered and stored properly to prevent excessive moisture loss before setting, if the temperature in the machines was maintained at 100oF., if eggs were turned frequently, if sanitation was good, and if your ventilation was properly adjusted during incubating and hatching. Attempting to increase the wet bulb reading to 90 or 92oF. may decrease hatch if vents on the incubators and hatcher are closed too much. Closing the vents may increase the wet bulb reading and humidity inside the machines, but the developing embryos suffer from poor ventilation.

Old, dirty, too short, and wrong-sized wicks on wet bulb thermometers can cause erroneous readings. It is essential that wicks be kept in the best condition. You should thoroughly clean the wicks weekly and replace them with new ones after four to eight washings. Regular changing of wicks is often thought to be unnecessary; it may not be, but if the relatively small cost of new wicks is compared to the cost of low hatchability caused by incorrect wet bulb readings, the new wicks are justified every time.

Inferior wicks tend to give higher readings than are actually present. In other words, the wet bulb tends to act more like the dry bulb. This is because the flow of water through the wick has been slowed. Therefore, if attempting to maintain an 86oF. wet bulb reading with faulty wicks, you may actually have an 84oF. wet bulb environment in the machine. The two degrees difference for an entire incubation and hatch period can noticeably reduce hatchability. Where possible and practical, use a dual set of wet and dry bulb instruments in each machine.

Excessive moisture loss from the eggs during storage before setting can produce the same symptoms that low humidity in the machines produces. A sign of low humidity is sticky embryos during pipping and hatching that results in embryos not being able to turn themselves in the shell and complete the act of pipping and detaching themselves from the shell. Low humidity also results in short down on the chicks, malformed, malpositioned, weak, and small chicks. Low humidity contributes to (but is not wholly responsible for) spraddlers, star gazers, and those that cannot stand, walk, or orient themselves well enough to reach food and water.

If several large, soft bodied, mushy chicks are observed that make it through pipping and hatching but are dead in the tray, it is a sign of high humidity. A bad odor usually accompanies this condition. The condition normally occurs only in incubators and hatchers that have forced spray humidity systems that force too much moisture into the machines. Rarely does humidity run too high in a machine that relies on evaporation from pans if you are using the recommended evaporative pans, if the temperature is correct, and if the machines are properly and amply ventilated with fresh air.

If by restricting ventilation the humidity is made too high (92o to 94oF.) during the final stages of incubation, the embryos are moist and develop to the 19th, 20th, or 21st day of incubation, but die in the shell from suffocation. This suffocation results from improper ventilation rather than high humidity.

VENTILATION OF INCUBATORS AND HATCHERS

Ventilation is important in incubators and hatchers because fresh oxygenated air is needed for the respiration (oxygen intake and carbon dioxide given off) of developing embryos from egg setting until chick removal from the incubator. The oxygen needs are small during the first few days compared to the latter stages of development.

Egg shells contain three to six thousand small holes, called "pores", through which oxygen passes from the air to the developing embryo and through which carbon dioxide passes from the embryo to the outside air. The embryo's lungs are not developed during early embryonic development to the point that they can accommodate respiration by breathing. Respiration, therefore, is provided during the first three to five days by the vitelline blood circulation plexus growing from the embryo. To reach this plexus the gaseous exchange must travel through the egg pores and the albumen (egg white) to reach the vitelline circulation, which lies on the surface of the egg yolk. After the 4th or 5th day of development another structure, called the "allantois," grows from the embryo, extends through the albumen, and positions itself just underneath the egg shell. The allantois becomes the primary respiratory organ of the developing embryo and remains such until just before pipping begins. The transfer of respiratory function from the allantois to the lungs begins three or four days before pipping. The transfer is gradual and is completed by the time the chick finishes pipping the egg shell.

The important thing to remember about embryonic respiration is that ventilation is important throughout the incubation process, especially toward the end, because the embryos are larger and respiring at a much higher rate than in the beginning.

So how should you set the dampers (air inlet and outlet regulators) in your incubator? Since there are so many different makes and models, it would be too difficult to attempt to recommend a procedure for each one. Instead, here are some general guidelines for proper ventilation:

- The air exhausted from a hatcher or incubator should be vented (ducted) to the outside of the building. This is especially true if the incubator is located in a closed building or a small room. Such a venting system, if properly installed, provides added assurance that fresh air is available to the developing embryos. Nearly all of the large commercial poultry hatcheries are set up with this type of venting system.

- Small, home-type incubators are usually not designed for easy installation of vent ducts and, therefore, are seldom used. Instead, one may find four or five incubators operating in a 10'x12' room, exhaust air spilling into the room, and intake air being pulled in from the same room. Sometimes all the windows and doors will be closed to, as the owner says, "help hold the heat and humidity up in the incubator."

- Restricting the room ventilatior may help with temperature and humidity control, but ventilation suffers. In such an instance, the incubators are only able to circulate the stale, expelled air back through the machine that the embryos reuse for respiration. Recirculating stale exhaust air through the incubators can be reduced by placing the incubator in a large room with a few openings, or in a small room with a number of large openings (windows or doors). The best way is to either duct the used exhaust air outside and provide enough openings for fresh air to enter the room, or to provide plenty of openings for fresh air to enter and stale exhaust air to easily escape.

- The largest amount of air exchange is needed toward the end of the incubation period because the embryos are larger and respiring more.

- On large commercial incubators the dampers are always in the motion by slowly opening or closing unless they reach the point of being fully open or closed. Temperature inside the incubator regulates the opening and closing motion. If the thermostat is set on 100oF., the dampers begin to open when the temperature is above 100oF., and begin to close when the temperature is below 100oF. (The dampers are set so they never completely close.) With this method of control, the dampers tend to remain near the closed position during the winter months when colder air is being brought into the incubator. Conversely, during the late spring, summer, and early fall months, the warmer intake air usually causes the dampers to stay about half to full open. This same pattern fluctuates on a day-to-day basis in the spring by cool nights and hot days. During early embryonic development less heat is given off by the embryo and, therefore, the dampers tend to close more than they would be with embryos in the latter stages of development.

The summary explanation for manual damper setting in single stage incubators is as follows:

- Provide more ventilation as the embryos grow larger and as the outside temperature increases.

- Provide approximately the same total size intake and exhaust openings (some incubators have one intake and two or more exhaust openings).

- Give as much attention to proper ventilation as you do to temperature, humidity, etc.

- Provide a way to get rid of the exhaust air, especially in small closed type incubator rooms, so that the machines can take in fresh clean air.

- If multiple egg settings are made in the incubator, causing the embryos to be in various stages of development, environmental changes have the greatest influence on the need for damper change. Unless the intake air is quite cool, the damper openings should not be set more than one-half closed if the machine is almost full of eggs.

How can you tell if ventilation is poor?

The first thing noticed may be a poor hatch. Lack of proper ventilation can contribute to low hatchability if, after examining numerous dead embryos in the shell, the following conditions are observed:

- The majority of embryos reach the 19th or 20th day of incubation.

- They are not dehydrated.

- They are not malpositioned.

- The unabsorbed egg yolks appear to be disease free.

- The wet bulb reading usually ran closer to 90oF. rather than 86oF.

- The heating element is seldom on during latter stages of incubation.

- The dampers are not as open as expected.

Birds, including chickens and quail, turn their eggs during nest incubation. Nature provides nesting birds with the instinct and we know turning is necessary in incubating machines to attain full hatching potential of the eggs.

Do you know why egg turning is necessary for good hatching?

The albumen (white) of an egg contains virtually no fat particles and has a specific gravity near that of water. The yolk, however, has a relatively high fat content. Fats and oils have specific gravities lower than water and float on water. The egg yolk tries to do the same thing -- float on the albumen. If an egg is left in one position, the yolk tends to float upward through the albumen toward the shell.

The developing embryo always rests on top of the yolk. When an egg is turned, the yolk turns in the albumen so the embryo is again positioned on top of the yolk. Nature probably does this so the embryo is always in the best position to receive body heat from the mother hen sitting on the eggs.

If the egg is not turned, the yolk tends to float upward toward the shell and pushes the embryo nearer the shell. If the yolk travels rises enough, the developing embryo is squeezed between the yolk and shell. The embryo can be damaged or killed. Turning the egg causes the yolk to be repositioned away from the shell, making it safe for the developing embryo until time to turn the egg again.

Strands of twisted albumen extend from the yolk into the albumen toward both the small and large ends of the egg. These strands are called chalazae. They help keep the yolk away from the shell. The chalazae hold the yolk firmly in the egg's center until egg quality begins to deteriorate, as when an egg is placed in a 100oF. temperature incubator.

As the albumen becomes more watery, the chalazae lose their ability to hold the yolk in place, making it more important to turn the egg often after incubation begins. In general, the need for turning begins when eggs are set and remains until two or three days before the eggs begin pipping.

In large commercial incubators the eggs are turned automatically each hour, 24 hours a day. Eggs in small incubators in the home sometimes get turned only twice a day, once in the morning and again in the evening. If manual turning, it is best to turn the eggs for an odd number of times each day (i.e., 3, 5 or 7 times). The longest period that the egg remains in one position is during the night hours. Turning an odd number of times will alternate the nights that the same side of the egg is uppermost.

Some producers open an incubator, pull out a flat tray, and run their hands over the eggs. This, to them, is turning the eggs. Actually it is only stirring the eggs, because there is no definite way to tell if the eggs are just rolled around or if they actually end up in a different position. Many of the eggs may not get turned at all -- just rolled around. Turning eggs in this manner can also crack the egg shells. Many chicks develop in eggs with cracked shells (only the shell, not the membranes) but not many will pip and completely hatch because dehydration occurs and makes the environment sticky. The chick doesn't have enough strength to pip and free itself from this sticky environment.

If using a relatively small incubator, you work away from home, and can turn the eggs only a few times a day, mark X on the top side of each egg with a pencil or felt tip pen. Each time you turn the eggs, visually check to see if each egg is actually turned by making sure the X ends up on the opposite side from where it was before turning. If using a machine that turns the eggs automatically, the eggs should be turned at least once every two hours. If the turning system is manual, turn as often as practical. Try to allow an equal time on each side.

Eggs should not be turned within three or four days of hatching. Chicks need to position themselves for pipping and do this better if allowed to remain still while that process takes place. The embryo is large enough by this time that it has used most of the yolk for food and is no longer in danger of being squeezed between the yolk and shell.

All incubatior factors like temperature and humidity can be operating just right but poor hatchability can result because of poor sanitary practices. Poor sanitation causes not only poor hatch but subsequent early death loss during brooding. It can also cause a lingering morbidity problem that sometimes affect the birds during the grow-out period. Losses during the brooding and grow-out period caused by poor hatchery sanitation can cause more monetary loss than the loss from poor hatchability.

Let's assume you are setting clean, well cared-for eggs.

The most important tools available for use in cleaning and disinfecting an incubator and hatcher are water, detergent, and elbow grease. Some people mistakenly think disinfecting agents are the answer to their problems. They think disinfectants can replace poor cleaning, but this simply is not true.

Remember this: It is almost impossible to disinfect a dirty environment. Why is this statement true? Because all disinfectants lose much of their effectiveness as soon as they come in contact with organic matter; the dirtier the surface being sanitized, the less effective the disinfectant being applied.

Some disinfectants are more effective in the presence of organic matter than others. Cresol, cresylic acid, and coal tar disinfectants are the most effective disinfectants in the presence of organic matter. Since they are corrosive and emit noxious and toxic gases, they are not normally used in incubators, but in cleaning and disinfecting bird houses and pens.

The most commonly used disinfectants in the hatchery are quaternary ammonia compounds (quats), multiple phenolics, and iodophors (iodine compounds).

Quaternary ammonia may be the most commonly used disinfectant for equipment like incubators and hatching trays because quats are relatively non-irritating, non-corrosive, of low toxicity, and reasonably effective in the presence of organic matter. Since the incubator and its components should be cleaned free of organic matter before applying a disinfectant, quats are a good choice.

Many hatcherymen use multiple phenolics. They have a wide germicidal range, low toxicity and corrosiveness, reasonably good effectiveness in the presence of organic matter, and good residual effect. The disadvantage is that multiple phenolics can cause a burning effect on the skin of anyone handling them in a strong solution or during a relatively long period of time. If using multiple phenolics at concentrations greater than the solution strength suggested on the label, wear rubber gloves for protection.

Iodophores have wide germicidal activity, good effectiveness in the presence of organic matter, and cost less than quats or multiple phenolics. The disadvantages are that it stains, is corrosive when in acid solution, and has only a slight residual activity.

A thorough cleaning job using plenty of elbow grease results in a 95 to 99 percent microbial removal. In such case, and when done often enough, little or no disinfectant is needed (assuming you are setting clean eggs). If, on the other hand, you are using a quick "hit or miss" system and a long time passes between thorough cleanup jobs, you are most likely falling short in disinfecting your machines. It is best to use a disinfectant following cleanup and maybe between cleanup jobs.

Fumigation is another method of disinfecting and is helpful when the cleaning is poor, the eggs are dirty, or the machines are filled with eggs, thus making it difficult to empty and clean properly. With clean eggs, machines, equipment, and intake air, fumigation is not needed.

Publications

News

STARKVILLE, Miss. -- Until an avian flu vaccine for chickens or other alternative is federally approved, commercial poultry operations in the U.S.

STARKVILLE, Miss. -- If egg prices have seemed higher than ever lately, it’s because they are, and consumers can place much of the blame squarely at the feet of the ongoing bird flu outbreak.

With highly pathogenic avian influenza, or HPAI, in the environment in Mississippi, owners of backyard flocks have to take extra steps to keep their chickens healthy.

Avian influenza poses an extremely low risk to human health and none to food safety in Mississippi, but its presence poses a risk to backyard flocks and the state’s $3 billion commercial poultry industry.