Information Possibly Outdated

The information presented on this page was originally released on November 23, 2010. It may not be outdated, but please search our site for more current information. If you plan to quote or reference this information in a publication, please check with the Extension specialist or author before proceeding.

MSU wood technology offers new possibilities

MISSISSIPPI STATE – Mississippi State University scientists have found a new way to turn wood into highly absorbent charcoal and automobile parts.

While wood has been used to manufacture charcoal since the early 1600s, the new technique can create charcoal and other carbon-based products with a higher absorption capacity. Charcoal has been used widely to treat water and clean up chemicals, but the production of magnetic charcoal creates new possibilities. Magnetic charcoal is more efficient in cleaning environmentally hazardous chemicals.

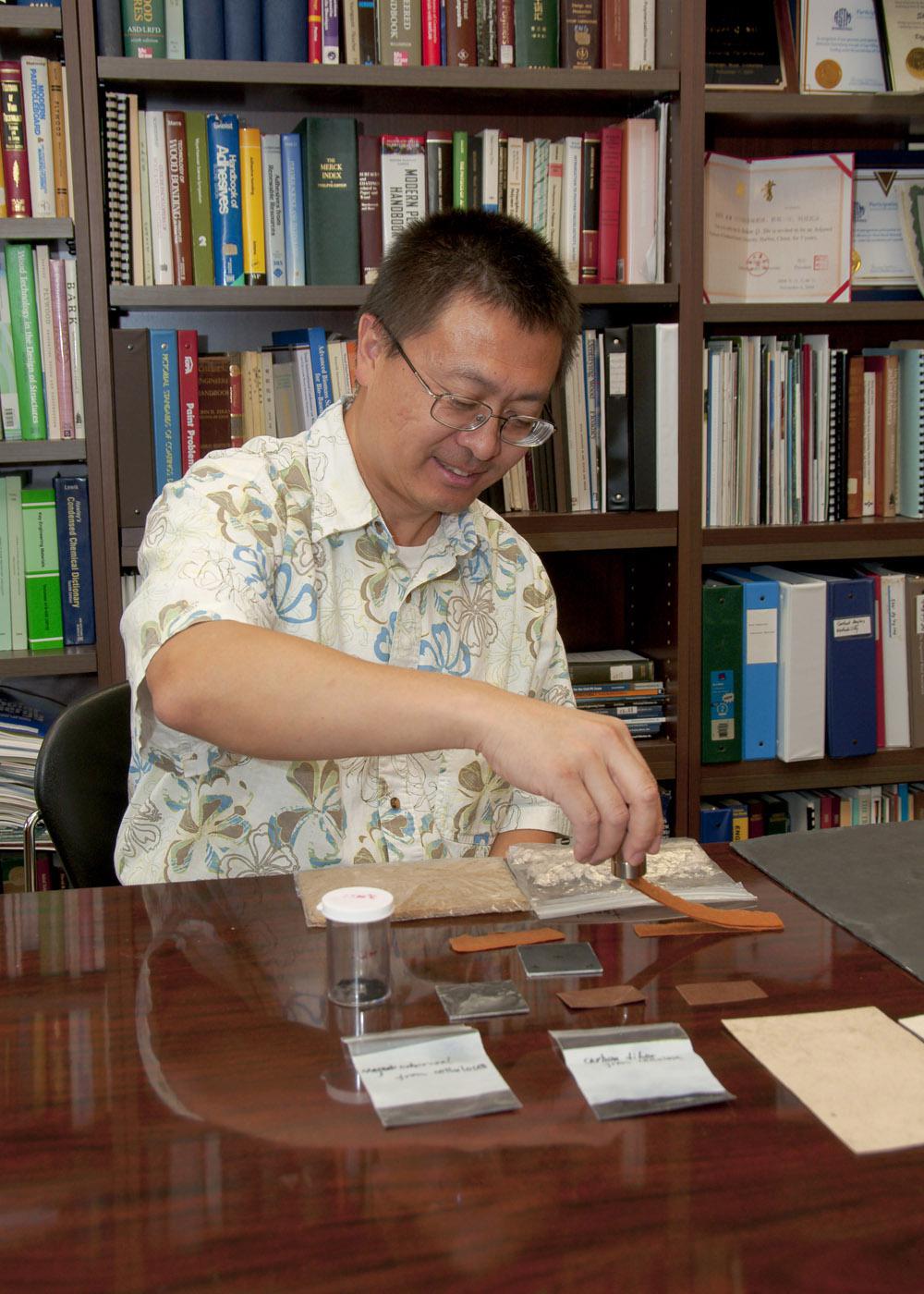

The process takes advantage of nanotechnology, which involves the creation, exploration and manipulation of materials measured in nanometers, or billionths of a meter. The unique process was developed in MSU’s Forest and Wildlife Research Center by forest products assistant professor Sheldon Shi and chemistry assistant professor Dongmao Zhang. The process can produce a variety of new products, including high-crystal carbon fibers, magnetic charcoal and other new carbon-based materials.

“The list of products that can be made from wood or agriculture-based materials and nanoparticles is almost unlimited,” Shi said. “We can create antiradiation materials to combat a nuclear accident or detoxification materials to assist in environmental cleanup.”

Although this technology is in an early stage of development, several studies have proven its usefulness. One possible use is filtering pigments, heavy motor oil and other additives from water. The new technique also produces wood-carbon materials that can be used in high-performance applications.

“We have found a method to use natural woody fibers, which are obtained from abundant and relatively inexpensive renewable resources, to develop carbon fibers,” Zhang said. “This could be of great benefit to the economy and the environment.”

The process uses wood and agriculture-based materials to develop a specialty natural fiber-polymer composite. The treated natural fibers can be formed into sheets or compressed into a mold.

Working with the MSU Center for Advanced Vehicular Systems, scientists have developed sheets and molded pieces that can be used by the automotive industry. Funding provided by the Department of Energy is allowing researchers to use the new materials to further develop lightweight vehicle designs.

MSU’s Office of Technology Commercialization plans to license the technology to interested companies.

“There is a lot of potential for this technology,” Shi said. “From cleaning up the environment and treating water to developing automobile parts, the use of wood and other biomass with nanoparticles provides so many possibilities.”

Contact: Dr. Sheldon Shi, (662) 325-3110