Solar-Powered Groundwater Pumping Systems for Livestock Watering

Solar-powered pumping systems (SPPS) are an option for remote areas that do not have easy access to the public power grid or municipal water supplies. They have been installed successfully in livestock watering applications and have proven reliable. Alternative power, such as an SPPS, is usually only considered when the total cost is cheaper than hooking into the public power grid. Running electrical lines distances of over one-third of a mile can become cost-prohibitive to operate a single water pump. So, if you are in a situation where tapping into the public power grid is not feasible, SPPS is an option to pursue. The information provided here will include the key concepts, equipment needed, and associated costs of installing an SPPS system.

Relevant Water Law in Mississippi

In Mississippi, all water belongs to the citizens of the state, which means water is managed by the state (Mississippi Department of Environmental Quality). In 1985, the Mississippi legislature passed a law that gives you the right to use water that borders your land. The law says that a landowner can make “reasonable” use of the water as long as it doesn’t “unreasonably” interfere with the rights of other landowners along that same waterbody. The 1985 law also allows landowners to use water under their property, but landowners are required to get a permit from the government to use this water. However, there are some exemptions, such as people using water only for domestic purposes. Also, permits are not required to use groundwater from a well with a surface-casing diameter of less than 6 inches (unless a person is developing property for resale and wants to use groundwater to maintain or enhance a pond for aesthetic purposes). Permits are issued for no longer than 10 years (or 5 years in the Mississippi Delta), and water-well drillers must be licensed.

Costs and Configurations

The cost of an SPPS depends primarily on the geography of the well site and on the configuration of the pumping system. The deeper the water table at your well location, the more expensive it will be to drill the well. In addition, an SPPS for a deeper well will be more expensive because pump size and power requirements increase with well depth. Cost and configurations of an SPPS can vary dramatically and should be analyzed on a case-by-case basis.

Because no or very little power is generated from solar panels at night and during cloudy and overcast days, the configuration of your system must take this into account. For example, livestock need daily access to clean water, so a large stock tank or a storage tank that can hold several days’ supply will be needed to get through the times that the solar panels are not generating power.

Direct current (DC) pumps are commonly used in SPPS because the power generated by solar panels is also DC. There are interfaces that allow you to bypass your solar system and run your pump using a standard alternating current (AC) generator during low-sunlight periods. In addition, a bank of batteries charged by the solar panels can be used to run the pumps. In a battery-operated system, pumping is not limited to the daylight hours. A complete system that can meet the watering needs of a livestock operation can cost anywhere from $5,000 to $10,000 (including the cost of drilling a well). Final costs are influenced by geography and final configuration of the SPPS.

Peak Sunlight Hours

Peak sunlight hours (PSH) are important to estimate for your well location. With this information, you’ll be able to estimate how long your pump will run each day and how many gallons you can pump. PSH is not the same as “hours of sunlight.” A peak sunlight hour is defined as 1,000 watts of solar energy striking a 1-square-meter area for 1 hour. PSH usually excludes early-morning and late-afternoon sunlight hours because the sun’s solar energy is not intense enough.

Based on information from the National Renewable Energy Laboratory (NREL), Mississippi receives 4.5 to 5.2 PSH per day. In contrast, New Mexico receives about 6.0 to 8.5 PSH per day. An SPPS in New Mexico has the capability to pump more gallons per day (gpd) than the exact same SPPS in Mississippi simply because the solar panels will receive sunlight for a longer portion of the day. The South receives more PSH per day than the Northeast and parts of the Midwest but much less than some of the Southwest and Western states.

SPPS Components

Water Well

There’s no need for an SPPS without a well! Contact a local, licensed water-well contractor to help with the process.

Photovoltaic (PV) Modules and Arrays

PV modules are what most people probably refer to as solar panels. They are rectangular and, when connected to other modules, they make up a PV array. Once all the necessary equipment is connected to the PV array and electricity is being generated, it is a fully functioning PV system.

The price of PV modules has decreased over the last decade, but they are still costly up front, especially for larger systems. Fortunately, the pumps used in an SPPS system do not require much power, so usually one to two modules will suffice. PV modules range in output power from 100 to 365 watts (W). To put this into perspective, one 325 W solar module could power just over three 100 W light bulbs or about 40 LED lights. This is why a large space is required (usually the roof) to connect multiple solar modules and get enough power to make a dent in the amount of energy that a residential home consumes. The price per watt of a solar module is anywhere between $1 and $1.50 (installation cost not included), which means that a 325 W solar module might cost between $325 and $485. There are a number of reputable companies that manufacture PV modules, and they can be easily purchased online.

DC Pump

The most expensive part of an SPPS is the DC pump. PV modules output power as DC, which means that, to run a standard AC pump, an inverter is required. It is more economical to use a pump that operates on DC and forego the cost of an inverter.

There are a lot of DC pumps on the market, but it is critically important that the one you choose meets your pumping requirements. The pump must have enough lift to get the water out of your well, and it must be able to pump enough water to meet your daily water needs. The capacity of most pumps is usually rated in gallons per minute (gpm), but this can easily be converted to gallons per hour (gph) or gpd. It is also important that the power output of the solar array match the power requirements of the pump. Voltage range (volts), power (watts), and maximum current (amps) are the most important pump specifications to consider. The total power that a pump requires is calculated by multiplying volts by amps (watts = volts × amps).

Pump Controller and Float Switch

The pump controller is the “brain” of an SPPS. The pump, PV array, and flotation switch all connect to the controller. It recognizes signals from the flotation switch in the stock tank or the low-water sensor in the pump and turns the pump on and off. A good pump controller and flotation switch can cost $500 or more.

Storage Tank or Stock Tank

For livestock operations, it is recommended to have a tank large enough to hold three days’ worth of average demand. The size and cost of the tank needed will vary depending on the number and type of livestock that need to be watered. Water can be pumped directly into a large, open stock tank, or it can be pumped into a closed storage tank that gravity feeds into the stock tank. It is easiest to pump directly into a stock tank, but if your daily water demand is high, it might be hard to find a tank that is big enough to meet your needs.

Additional Components

- Materials to mount PV array (pole, brackets, rack, etc.)

- Tubing or piping to convey water to tank

- Wiring

- Tank flotation switch

- Fencing or some kind of effective protection from curious and heavy livestock

SPPS Example Scenario and Estimated Cost

Below is a scenario to help explain what goes into calculating solar pump sizes. In this scenario, water is being pumped into a large stock tank.

General Information

Well depth = 225 ft

Static water level = 100 ft (distance from top of well to groundwater level during undisturbed, no-pumping conditions)

Well draw down = 25 ft

Pumping level = 125 ft (static water level + well draw down)

Vertical rise = 5 ft (distance from ground to top of pipe feeding stock tank)

Water requirements: 50 cattle at 20 gpd each = 1,000 gpd

Peak sunlight hours (PSH) = 4.5 (Mississippi ranges from 4.5 to 5.2)

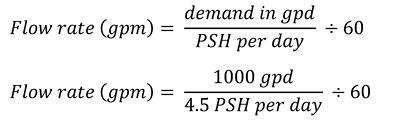

Calculating Flow Rate

Flow rate (gpm) = 3.7 gpm

Calculating Total Dynamic Head Loss

Total dynamic head is the height that water needs to be pumped. The greater the total dynamic head, the more energy needed to pump water from the ground.

total dynamic head (ft) = pumping level (ft) + vertical rise (ft) + friction loss (ft)*

*Friction loss can be calculated fairly easily using friction loss tables for pipes and fittings, but, for the sake of this example, we will make a rule of thumb adjustment that multiplies pumping level and vertical rise by 1.1.

total dynamic head (ft) = pumping level (ft) + vertical rise (ft) x 1.1

total dynamic head = 125 ft + 5 ft x 1.1

total dynamic head = 143 ft

Pump Sizing

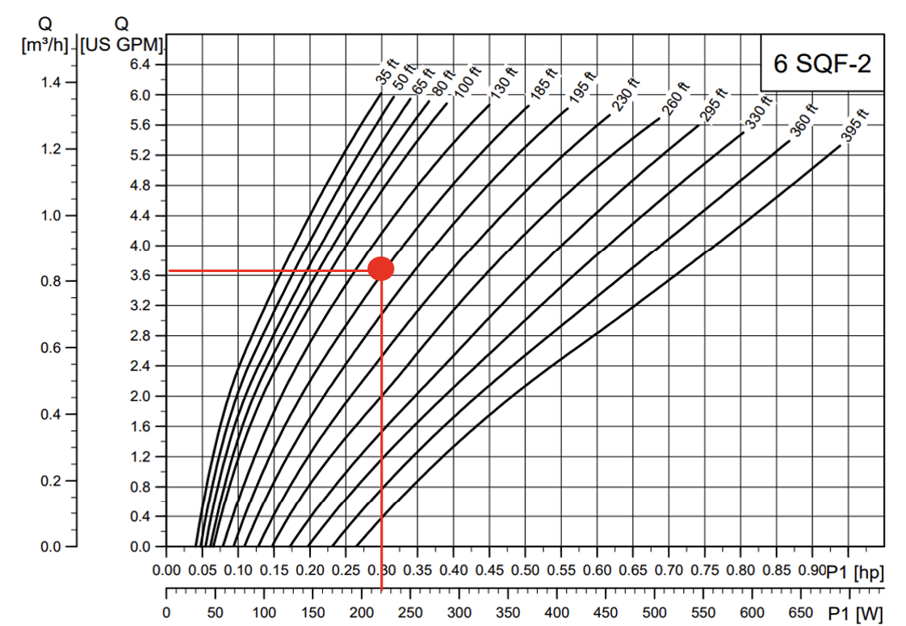

Now that our desired flow rate and total dynamic head have been calculated, we can begin to search for pumps that meet our criteria. Figure 1 shows the pump curve for a Grundfos 6 SQF-2 submersible pump. The dot on the graph indicates where the desired flow rate (y-axis) and the total dynamic head intersect. Total dynamic head is shown at the end of each curve and ranges from 35 to 395 feet. The advantage of using the pump curves is that we can also get the amount of power that we need to operate the pump given our specified conditions. From the x-axis on this graph, we see that approximately 220 watts are required. This pump can run on voltages that range from 30 to 300 volts DC, which means that the more power supplied to the pump, the higher the flow rates and the deeper it can go in a well.

Solar Array Sizing

From Figure 1, we determined that 220 W should provide enough power to operate the pump. When it comes to sizing solar arrays, it is wise to overestimate the power requirements by a factor of roughly 1.25. Oversizing the system allows for energy losses that will inevitably occur in the solar modules, controllers, and wiring. So, for this scenario, we require 290 W instead of 220 W (220 × 1.25 = 290). This is good news because the pump can be operated using one to two solar modules. When choosing solar modules for a pump, it is important to make sure the output of the solar panels matches the power requirements of the pump. As an example, the 6 SQF-2 pump operates at a minimum voltage of 30 volts DC. If you buy a solar module that only outputs 12 volts DC, the pump will not operate. Many solar modules do output more than 30 volts DC, so this is not a huge issue, but it is something to take into consideration. If you are not comfortable with basic electrical concepts, it would be wise to contact an expert to help you make sure your system will funtion properly and reliably.

Estimate Cost

Table 1 shows the estimated cost for the example SPPS presented here.

Table 1. Estimated cost for an SPPS system.

|

Item |

Amount |

Price per item ($) |

Cost ($) |

|

Grundfos 6 SQF-2 submersible pump |

1 |

2,000 |

2,000 |

|

Solar panel/PV array (W) |

325 |

1.25 |

405 |

|

Grundfors CU 200 pump controller |

1 |

500 |

500 |

|

Pump float switch |

1 |

75 |

75 |

|

Material to mount solar module |

1 |

100 |

100 |

|

Wiring (ft) |

150 |

1.50 |

225 |

|

Piping (ft) |

150 |

1.25 |

190 |

|

Installation of SPPS |

1 |

1,000 |

1,000 |

|

Well (ft) |

225 |

20 |

4,500 |

|

Bottomless stock tank with liner (gal) |

3,544 |

0.67 |

2,400 |

|

Total |

11,395 |

Conclusions

Solar power pumping systems have been used for over 20 years in the United States and have proven to be reliable. These types of systems are not applicable in all scenarios, but they are a viable option and are worth considering in areas with limited access to power. The final cost of an SPPS depends on a number of factors, but they are generally more expensive to install than a pump tied to the public electric grid.

References

Van Pelt, R., Weiner, C., & R. Waskom. (2012). Solar-powered groundwater pumping systems. Fact Sheet No. 6.705. Colorado State University Extension.

Publication 3236 (POD-06-23)

By John Linhoss, PhD, former Extension Associate; Mary Love Tagert, PhD, Associate Extension Professor; and James Wooten, Extension Associate; Agricultural and Biological Engineering.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.