Mississippi Beef Cattle Producer Pocket Guide

Monthly Mississippi Beef Cattle Management Calendar

Forage Classifications and Characteristics

Environment: Best Management Practices

Rotational Stocking Guidelines

Forage-related and Nutritional Disorders

Beef Cattle Water Intake Estimates

Relative Feedstuff Value with Selected Corn and Soybean Meal Prices1

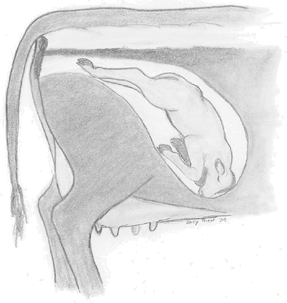

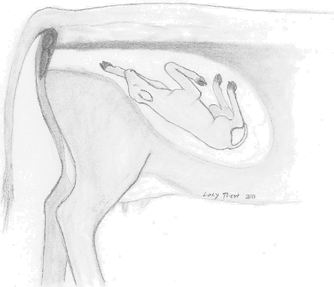

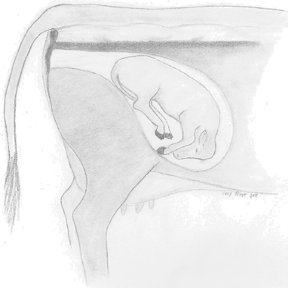

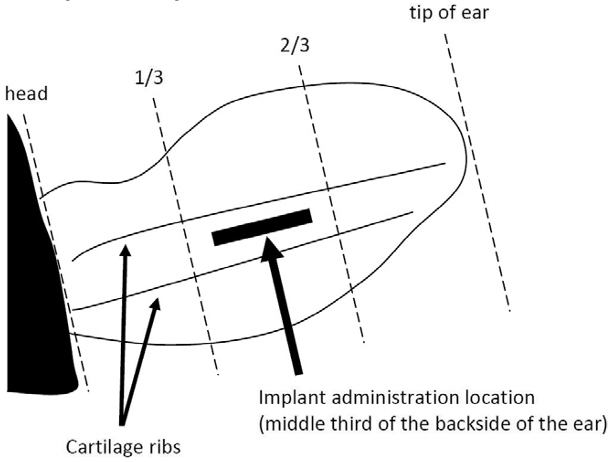

Stages of Female Reproduction in Cattle

Normal Estrous Cycle of Cattle

Measures of Reproductive Efficiency

Timeline for Estrus (Heat) Signs in Cattle

Bull Breeding Soundness Evaluation (BSE)

Benefits of Controlled Breeding and Calving Season

Description of Reproductive Tract Scores

Udder Suspension and Teat Size Scores

Guidelines for Aging Cattle by Teeth

Economically Relevant Traits (ERT)

Matching Genetic Potential to Production Environment

Expected Progeny Differences (EPDs)

Traits Controlled or Largely Influenced by One Gene Pair

Market (Cull) Cow Price Classes

Beef Cattle Marketing Channels

Beef Cattle Enterprise Financial Statements

Annual Payments ($ of Principal and Interest) to Amortize a $1,000 Loan

Beef Cattle Enterprise Financial Measures

Biological Risk Management (Biosecurity)

Identifying Sick or Injured Cattle

Beef Quality Assurance (BQA) Marketing Code of Ethics

Hurricane Preparedness Checklist

Beef Carcass Primal (Wholesale) Cuts

Introduction

Beef Cattle Production in Mississippi

Beef cattle production is a significant component of Mississippi agriculture. The total value of production of cattle and calves in Mississippi contributes millions of dollars annually to the local economy and ranks highly among the state’s agricultural commodities. Cow-calf and stocker cattle operations are very prominent parts of the Mississippi beef cattle industry.

Mississippi State University Extension Service

This pocket guide was authored by beef cattle specialists with the Mississippi State University Extension Service. Extension’s overall purpose is education. Extension provides research-based information, educational programs, and technology transfer focused on issues and needs of the people of Mississippi. Extension recognizes that agriculture and its related enterprises are of major economic importance in Mississippi, and directs programs and resources to reflect this importance. Extension state beef cattle specialists, area livestock/forages agents, and county directors are available to assist beef cattle producers.

http://extension.msstate.edu/agriculture/livestock/beef

Mississippi Beef Cattle Improvement Association

The printing of this pocket guide was funded by the Mississippi Beef Cattle Improvement Association (MBCIA). The MBCIA encourages the production and identification of genetically superior animals by purebred breeders and promotes the use of these animals by commercial producers through sale offerings.

The purposes of the MBCIA are to:

- promote the use of performance records as a tool for herd improvement

- emphasize economically important traits that can be improved through selection and culling based on performance records

- encourage good management practices

Member benefits include access to and information about:

- monthly MBCIA newsletter

- annual membership meeting

- bull marketing programs

- centralized bull testing programs

- Hinds Community College Bull Test

- Gain-on-Forage Bull Test

- ultrasound body composition scanning

- Miss Premium replacement heifers

- feeder calf marketing programs

- Mississippi Farm to Feedlot program

- Cattlemen’s Exchange groups

- BIF producer award nominations

- MBCIA educational projects

The MBCIA promotes the use of high-quality Mississippi-raised bulls as herd sires. These bulls are better adapted to the local environment than cattle from other regions. Mississippi-raised herd sires can be readily compared with other bulls on a national basis using expected progeny differences. Breed-leading genetics are found in Mississippi bulls of many breeds. Beyond bulls, Mississippi is home to well-managed feeder calves and heifers. Purchasing high-quality cattle locally reduces freight costs and supports the local economy.

Demand EPDs. Demand health records. Demand Mississippi cattle.

Monthly Mississippi Beef Cattle Management Calendar

|

January |

February |

March |

|---|---|---|

|

General Recommendations |

||

|

Control lice Supplement as needed (energy, protein, Vit. A) Prevent grass tetany Gather income tax records Set yearly goals |

Control lice Supplement as needed (energy, protein, Vit. A) Prevent grass tetany Fertilize cool-season forages Control weeds Collect soil samples Gather income tax records Attend MBCIA meeting |

Control lice Prevent grass tetany Control weeds Service forage harvesting equipment Prepare income taxes |

|

Spring-calving Recommendations |

||

|

Monitor calving Acquire herd sires, semen, and breeding supplies Collect yearling data |

Monitor calving Acquire herd sires, semen, and breeding supplies Collect yearling data |

Monitor calving Administer pre-breeding vaccinations and deworming Acquire herd sires, semen, and breeding supplies Perform bull BSEs Collect yearling data |

|

Fall-calving Recommendations |

||

|

End breeding |

Diagnose pregnancy Cull open females |

Diagnose pregnancy Cull open females Plan pre-weaning vaccinations |

|

April |

May |

June |

||

|---|---|---|---|---|

|

General Recommendations |

||||

|

Prevent grass tetany Start fly control as needed Deworm cattle Plant warm-season forages Fertilize warm-season forages Meet income tax deadline |

Provide adequate shade Reduce cattle heat stress Control flies Plant warm-season forages Fertilize warm-season forages |

Provide adequate shade Reduce cattle heat stress Control flies Test stored forage for quality Monitor feed prices Be prepared as hurricane season begins |

||

|

Spring-calving Recommendations |

||||

|

Begin breeding |

Continue breeding |

End breeding season |

||

|

Fall-calving Recommendations |

||||

|

Wean calves (deworm and vaccinate) Precondition calves Cull herd for performance and health Select replacements Deworm adults at weaning |

Wean calves (deworm and vaccinate) Precondition calves Cull herd for performance and health Select replacements Deworm adults at weaning |

Precondition calves |

||

|

July |

August |

September |

|---|---|---|

|

General Recommendations |

||

|

Provide adequate shade Reduce cattle heat stress Control flies Deworm adults and yearlings Test stored forage for quality Monitor feed prices Be prepared as hurricane season continues |

Provide adequate shade Reduce cattle heat stress Control flies Test stored forage for quality Monitor feed prices Be prepared as hurricane season continues |

Provide adequate shade Reduce cattle heat stress Control flies Plant cool-season forages Fertilize cool-season forages Test stored forage Monitor feed prices Be prepared as hurricane season continues |

|

Spring-calving Recommendations |

||

|

Diagnose pregnancy Cull open females |

Diagnose pregnancy Cull open females Plan pre-weaning vaccinations |

Wean calves (deworm and vaccinate) Precondition calves Cull herd for performance and health Select replacements Deworm adults at weaning |

|

Fall-calving Recommendations |

||

|

Prepare for calving |

Prepare for calving |

Monitor calving Acquire herd sires, semen, and breeding supplies Collect yearling data |

|

October |

November |

December |

|

|---|---|---|---|

|

General Recommendations |

|||

|

Monitor feed prices Supplement as needed (energy, protein, Vit. A) Plant and fertilize cool- season forages Be prepared as hurricane season continues |

Control lice Monitor feed prices Supplement as needed (energy, protein, Vit. A) Be prepared as hurricane season continues Plan holiday labor |

Control lice Supplement as needed (energy, protein, Vit. A) Prevent grass tetany Plan holiday labor Make end of tax year purchases and sales |

|

|

Spring-calving Recommendations |

|||

|

Wean calves (deworm and vaccinate) Precondition calves |

Prepare for calving Precondition calves |

Prepare for calving |

|

|

Cull herd for performance and health Select replacements Deworm adults at weaning |

|

|

|

|

Fall-calving Recommendations |

|||

|

Monitor calving Administer pre-breeding vaccinations and deworming Acquire herd sires, semen, and breeding supplies Perform bull BSEs Collect yearling data |

Monitor calving Begin breeding Acquire herd sires, semen, and breeding supplies Collect yearling data |

Continue breeding |

|

Beef Cattle Terminology

Ad libitum: free choice; allowing animals to eat all they want; on full feed

Bloom: haircoat has a luster (shine) that gives the appearance of a healthy animal

Breed character: a combination of masculine or feminine qualities with ideal breed type features. Head and color markings are given considerable attention in estimating breed character

Brindle: coat coloring pattern with narrow, vertical, alternating stripes of black and red pigmentation; base color may range from light red or fawn to dark brown or even nearly white; “tiger striped”

Brockle-faced: white-faced with other colors splotched on face and head; mottle-faced

Broken mouth: some teeth missing or broken

Bull: male bovine animal, usually of breeding age

Bullock: young bull, typically less than 20 months of age

Bunk breaking: process of acclimating calves to consume feed from a bunk or other feeder

Calf-feds: cattle placed on feed as calves and finished at less than 16 months of age, usually on feed for 150 to 200 days, and placed in the feedlot directly following weaning.

Cancer eye: cancerous growth on eyeball or lid

Closed herd: herd in which no outside breeding cattle are introduced

Colostrum: first milk produced by a female after calving; high in antibodies that protect calves from invading microorganisms

Concentrate: feed high in energy, low in fiber, and highly digestible; typically grains

Cow: sexually mature female bovine animal that has usually produced a calf

Creep feeding: providing supplemental nutrients to nursing calves through the use of gates or exclosures which allow calves but not cows to access the creep feed or forage

Cryptorchid: male with one or both testicles retained in abdominal cavity

Cwt: abbreviation for hundredweight (100 lb.)

Dam: female parent

Diet: a controlled selection of feedstuffs provided on a continuous schedule

Dark cutter: color of muscle in carcass has a dark appearance, often results in price discount

Depreciation: decrease in value of an asset due to age, use, and obsolescence; pro-rated expense of owning an asset

Drench: to give fluid by mouth

Dry (cow): non-lactating cow

Dystocia: difficult birth

Efficiency: ratio of output to input

F1: offspring resulting from mating a purebred bull to purebred females of another breed

Fed cattle: steers and heifers that have been fed concentrates, usually for 90 to 120 days in a feedlot

Feeder cattle: cattle that need further feeding prior to slaughter

Fill: contents of the digestive tract

Finish: degree of fatness of an animal

Flushing: placing females on a high level of nutrition before breeding to decrease postpartum interval and possibly stimulate an increased conception rate

Freemartin: female born twin to a bull; the female is sterile about 90% of the time

FOB: free on board; buyer pays freight after loading

Grid: method of pricing slaughter cattle which offers premiums and discounts for cattle; cattle which are leaner and have a higher quality grade receive premiums; grids generally have other specifications for carcass weight and dark cutters

Hard keeper (doer): animal that does not do well

Heifer: young female bovine animal prior to the time she has produced her first calf

Heiferette: heifer that has calved once, after which she is fed for slaughter; the calf has usually died or been weaned at an early age

NPN (nonprotein nitrogen): nitrogen in feeds from substances such as urea and amino acids, but not from preformed proteins

Off feed: animal refuses to eat or consumes only small amounts of feed

Open: non-pregnant cow or heifer

Pay weight: actual weight for which payment is made; in many cases it is the shrunk weight (actual weight minus pencil shrink)

Pencil shrink: deduction (percent of liveweight) from an animal’s weight to account for fill

Phenotype: characteristics of an animal that can be seen and/or measured

Polled: naturally or genetically hornless

Pons: accumulation of fat over pin bones

Postpartum interval: length of time from calving until the dam is pregnant again

Preconditioning: preparation of feeder calves for marketing and shipment; may include vaccinations, castration, and training calves to eat and drink in pens

Prolapse: abnormal protrusion of part of an organ, such as the uterus or rectum

Purebred: animal eligible for registry with a recognized breed association

Ration: feed offered during a 24-hour period

Scurs: small growths of hornlike tissue attached to the skin of polled or dehorned animals

Shipping fever: respiratory disease of cattle

Sire: male parent

Supplement: mixture of nutrients added to the diet to meet nutrient shortages not supplied by the forage or grain of the base diet

Stag: bovine male castrated after puberty

Steer: bovine male castrated prior to puberty

Stocker: weaned calf fed high-roughage diets (including grazing) before going into a feedlot

Terminal sire: sire used in a terminal crossbreeding program where the sire’s offspring are intended to be sold as market animals

Thermoneutral zone (TNZ): range in temperature where rate and efficiency of gain is maximized; comfort zone

Total mixed ration (TMR): all feed ingredients mixed together in a nutritionally balanced ration and fed to the animal rather than each ingredient being fed individually

Type: physical conformation; physical traits that contribute to animal value for a specific purpose

Undegradable intake protein (UIP): protein not fermented in the rumen but digested in the small intestine; escape or bypass protein

Yardage: charges incurred each day that cattle are in the feedlot, usually expressed on a cents per head per day basis

Adapted from R. E. Taylor. Beef Production and Management Decisions. 2nd ed. 1994; www.eXtension.org. 2012. Beef Cattle Glossary.

Mississippi Frost Dates

|

Mississippi Location |

Average Date of First Frost |

Average Date of Last Frost |

|---|---|---|

|

Batesville |

October 15 |

April 14 |

|

Biloxi |

November 24 |

March 8 |

|

Brookhaven |

October 26 |

April 5 |

|

Carthage |

October 21 |

April 8 |

|

Corinth |

October 14 |

April 14 |

|

Greenville |

November 2 |

March 27 |

|

Greenwood |

October 31 |

April 1 |

|

Grenada |

October 19 |

April 11 |

|

Hattiesburg |

November 3 |

March 29 |

|

Hernando |

October 27 |

April 7 |

|

Holly Springs |

October 11 |

April 18 |

|

Jackson |

October 29 |

April 5 |

|

Laurel |

November 3 |

March 30 |

|

McComb |

November 3 |

April 1 |

|

Meridian |

October 25 |

April 6 |

|

Natchez |

November 7 |

March 27 |

|

Philadelphia |

October 22 |

April 6 |

|

Poplarville |

November 9 |

March 23 |

|

Starkville |

October 24 |

April 7 |

|

Tupelo |

October 20 |

April 16 |

|

Vicksburg |

November 6 |

March 30 |

|

Woodville |

November 11 |

March 24 |

|

Yazoo City |

November 3 |

March 31 |

Adapted from National Oceanic and Atmospheric Administration. 2011. Freeze/Frost Occurrence Data.

Forage Classifications and Characteristics

Forage Classifications

|

Classification criteria |

Classes |

|

|---|---|---|

|

Form and function |

Grasses: generally herbaceous (not woody) plants, parallel leaf veins, fibrous root systems, bear seed on elongated stem stalk, produce only 1 seed leaf; ex: bermudagrass, annual ryegrass |

Legumes: produce seed in a pod, netted leaf veins, tap root systems, produce 2 seed leaves; most interact with Rhizobium bacteria to fix nitrogen in root nodules; ex: clovers, alfalfa |

|

Lifespan |

Annuals: plants that germinate, grow, reproduce, and die in 1 year’s time or 1 growing season; reproduce only by seed; ex: crabgrass, wheat |

Perennials: plants that, under suitable conditions, have the ability to live for more than 1 year; may die back or become dormant and later recover from tubers, rhizomes, or stolons; reproduce vegetatively or by seed; ex: bahiagrass, alfalfa |

|

Growth season |

Warm-season forages: begin growth and/or are planted in the spring or early summer and make most of their growth during the warmest months of the year; ex: dallisgrass, pearl millet |

Cool-season forages: begin growth and/or are planted in the autumn or sometimes early spring and make most of their growth the year, except for the coldest periods of the winter; ex: tall fescue, white clover |

Characteristics of Forage Grasses

|

Forage Species |

Seedling Vigor |

Tolerance1 to Soil Acidity |

Tolerance to Poor Drainage |

Tolerance to Drought |

Tolerance to Grazing |

|---|---|---|---|---|---|

|

Warm-season perennial grasses |

|||||

|

Bahiagrass |

P |

E |

G |

E |

E |

|

Bermudagrass |

F |

E |

P |

E |

E |

|

Dallisgrass |

P |

F |

E |

G |

G |

|

Johnsongrass |

G |

F |

E |

G |

P |

|

Switchgrass |

P |

F |

F |

E |

P |

|

Warm-season annual grasses |

|||||

|

Corn |

E |

F |

P |

P |

P |

|

Crabgrass |

G |

G |

P |

F |

E |

|

Pearl millet |

E |

E |

P |

E |

F |

|

Sorghum |

G |

P |

P |

E |

F |

|

Sorghum-sudan |

E |

P |

F |

G |

F |

|

Cool-season perennial grasses2 |

|||||

|

Tall fescue E+ |

G |

G |

G |

G |

E |

|

Tall fescue E- |

F |

G |

G |

F |

F |

|

Cool-season annual grasses |

|||||

|

Annual ryegrass |

G |

G |

E |

F |

E |

|

Oats |

E |

F |

F |

F |

G |

|

Rye |

E |

G |

F |

F |

G |

|

Wheat |

E |

P |

P |

F |

G |

1E = excellent; G = good; F = fair; P = poor

2E+ = endophyte-infected; E- = endophyte-free Adapted from Ball et al. 1999. Forage Crop Pocket Guide. Intl. Plant Nutr. Inst., Norcross, GA.

Characteristics of Forage Legumes

|

Forage Species |

Seedling Vigor |

Tolerance1 to Soil Acidity |

Tolerance to Poor Drainage |

Tolerance to Drought |

Tolerance to Grazing |

|---|---|---|---|---|---|

|

Warm-season perennial legumes |

|||||

|

Perennial peanut |

Vegetatively propagated |

G |

P |

G |

F |

|

Sericea lespedeza |

P |

E |

F |

E |

P3 |

|

Warm-season annual legume |

|||||

|

Annual lespedeza |

F |

E |

F |

G |

G |

|

Cool-season perennial legumes |

|||||

|

Alfalfa |

G |

P |

P |

E |

P2 |

|

Red clover |

E |

F |

F |

F |

G |

|

White clover |

F |

F |

G |

F |

E |

|

Cool-season annual legumes |

|||||

|

Arrowleaf clover |

F |

F |

P |

G |

G |

|

Berseem clover |

G |

P |

E |

F |

F |

|

Caley pea |

G |

F |

G |

F |

F |

|

Crimson clover |

E |

G |

P |

F |

F |

|

Hairy vetch |

E |

G |

P |

F |

F |

|

Rose clover |

P |

G |

P |

G |

G |

|

Subterranean clover |

G |

G |

G |

F |

E |

1E = excellent; G = good; F = fair; P = poor

2Grazing-tolerant varieties are rated G

Adapted from Ball et al. 1999. Forage Crop Pocket Guide. Intl. Plant Nutr. Inst., Norcross, GA.

Forage Planting

Planting Information for Perennial Grasses in Mississippi

|

|

Adaptation |

Seeding Rate2, lb/acre |

Planting Depth, inches |

Optimum Planting Dates |

|

|

MS Area1 |

Soils |

||||

|

Bahiagrass |

N, C, S |

Moist, sandy bottoms to droughty uplands |

B: 15 to 20 |

¼ to ½ |

Early spring after frost; S only: late summer, fall |

|

Bermudagrass (seed propagated) |

N, C, S |

Well drained, light sand to clay loam |

Hulled B: 5 to 10 Unhulled B: 10 to 15 |

¼ to ½ |

Mar 15 to early summer |

|

Bermudagrass (vegetatively propagated) |

N, C, S |

Well drained, light sand to clay loam |

Rows: 10 bushels sprigs B: 30 to 40 bushels sprigs |

|

Late Feb to early summer with adequate soil moisture |

|

Dallisgrass |

N, C, S |

Moist, fertile, well drained |

B: 20 (10 pounds pure, live seed) |

¼ to ½ (Adjust for low germination) |

Feb 15 to May 15 |

|

Johnsongrass |

N, C |

Medium to heavy, fertile |

B: 20 to 30 D: 10 to 15 |

½ to 1 |

Apr to Jul |

|

Tall fescue |

N, C |

Moist, fertile bottoms; productive uplands; S only: heavy, moist soils |

B: 15 to 20 D: 10 to 15 |

¼ to ½ |

Sep to Oct |

1N = North; C = Central; S = South

2B = broadcast; D = drilled

Adapted from Ball et. Al. 2007. Southern Forages. 4th ed. Intl. Plant Nutr. Inst., Norcross, GA.

Planting Information for Annual Grasses

|

|

Adaptation |

Seeding Rate2, lb/acre |

Planting Depth, inches |

Optimum Planting Dates |

|

|

MS Area1 |

Soils |

||||

|

Pearl millet |

N, C, S |

Well drained, fertile (avoid lime soils) |

D: 12 to 15 B: 25 to 30 |

½ to 1 |

N: Apr 20 to Jul 1 C: Apr 15 to Jul 1 S: Apr 1 to Jul 15 |

|

Sorghum-sudan hybrids |

N, C, S |

Well drained, productive |

D: 20 to 25 B: 30 to 35 |

½ to 1 |

N: May 1 to Aug 1 C: Apr 15 to Aug 1 S: Apr 1 to Aug 15 |

|

Sweet and forage sorghum |

N, C, S |

Well drained |

B: 15 to 20 Syrup: D: 3 to 5 Silage: D: 4 to 6 |

1 |

Late Apr to May 15 S only: late as Jul 1 for forage types |

|

Sudangrass |

N, C |

Light sandy to heavy clay |

D: 20 to 25 B: 30 to 40 |

½ to 1 |

May 1 to Aug 1 |

|

Barley |

N, C |

Well drained, productive |

Grain: B: 75 to 100 Grazing alone: D: 75 B: 100 to 120 In mixtures: 60 to 75 |

1 to 2 |

Sep to Oct |

|

Oats, rye, wheat |

N, C, S |

Well drained, sandy to clay loams |

Grain: 60 to 90 Grazing alone: 90 to 120 In mixtures: 60 to 90 |

1 to 2 |

N: Sep 1 to Oct 1 C: Sep 1 to Oct 15 S: Sep 15 to Nov 1 Overseeded: 5 weeks later |

|

Annual ryegrass |

N, C, S |

Clay loam to sandy |

Grazing alone: B: 30 to 35; D: 25-30 In mixtures: 20 |

0 to ½ |

Same as for oats, rye, wheat |

1N = North; C = Central; S = South

2B = broadcast; D = drilled

Adapted from Southern Forages. 4th ed. Intl. Plant Nutr. Inst., Norcross, GA.

Planting Information for Perennial and Warm-season Annual Legumes

|

|

Adaptation |

Seeding Rate2, lb/acre |

Planting Depth, inches |

Optimum Planting Dates |

|

|

MS Area1 |

Soils |

||||

|

Sericea lespedeza |

N, C, S |

Well drained (avoid lime soils) |

B: 20 to 30 D: 15 to 20 |

¼ |

Mar to May |

|

Alfalfa |

N, C, S |

Deep, fertile, well drained |

B: 20 to 25 |

0 to ¼ |

N: Aug 15 to Oct 1 C: Sep 1 to Oct 1 S: Oct 1 to Nov 1 |

|

White and ladino clover |

N, C, S |

Moist bottoms and productive uplands |

B: 3 |

0 to ¼ |

Sep to Oct (also Feb to Mar in N, C) |

|

Red clover (acts as annual in south MS) |

N, C, S |

Moist bottoms and productive uplands |

D: 8 to 10 B: 12 to 15 |

¼ to ½ |

Sep to Oct |

|

Alyce clover |

S |

Fertile, well drained |

B: 15 to 20 |

¼ to ½ |

May 15 to Jul 15 |

|

Cowpeas |

N, C, S |

Well drained |

D: 30 to 40 B: 120 |

2 to 3 |

May 1 to Jun 15 |

|

Annual lespedeza |

N, C |

Well drained (avoid lime soils) |

B: 25 to 35 |

¼ to ½ |

Feb 15 to Mar 15 |

1N = North; C = Central; S = South

2B = broadcast; D = drilled

Adapted from Ball et. Al. 2007. Southern Forages. 4th ed. Intl. Plant Nutr. Inst., Norcross, GA.

Planting Information for Cool-season Annual Legumes

|

|

Adaptation |

Seeding Rate2, lb/acre |

Planting Depth, inches |

Optimum Planting Dates |

|

|

MS Area1 |

Soils |

||||

|

Caley peas |

Black Belt |

Black Belt soils; pH 6.5 or greater |

B: 50 |

½ to 1 |

Sep to Oct 15 |

|

Arrowleaf clover |

N, C, S |

Well drained, medium to very fertile |

B: 5 to 8 (scarified seed) |

0 to ½ |

N: Sep 1 to Oct 1 C: Sep 15 to Oct 15 S: Sep 15 to Nov 1 Overseeded: 5 weeks later |

|

Ball clover |

N, C, S |

Sandy loam to clay; tolerates moist soils |

B: 2 to 3 |

0 to ¼ |

Sep to Oct |

|

Berseem clover |

N, C, S |

Black Belt soils; tolerates moist soils |

B: 20 to 25 D: 10 to 15 |

¼ to ½ |

Sep |

|

Crimson clover |

N, C, S |

Well drained (avoid lime soils) |

B: 20 to 30 D: 15 to 20 |

0 to ½ |

Same as for arrowleaf clover |

|

Subterranean clover |

N, C, S |

Well drained, productive |

B: 8 to 10 |

¼ to ½ |

Sep to Oct |

|

Common vetch |

N, C, S |

Well drained |

B: 30 to 40 |

1 to 1½ |

N: Sep 1 to Oct 15 C: Sep 1 to Oct 15 S: Sep 15 to Nov 1 |

|

Hairy vetch |

N, C, S |

Well drained |

B: 20 to 25 |

1 to 1½ |

Same as for common vetch |

1N = North; C = Central; S = South

2B = broadcast; D = drilled

Adapted from Ball et. Al. 2007. Southern Forages. 4th ed. Intl. Plant Nutr. Inst., Norcross, GA.

Environment: Best Management Practices

Goal: to conserve and protect soil, water, and air resources

- Develop and implement a comprehensive nutrient management plan

- Test soil to determine fertilizer needs

- Use most suitable fertilizer based upon crop, application method, and climatic conditions

- Apply with proper rate, technique, and timing

- Maintain and calibrate equipment

- Inject or incorporate fertilizer applications

- Avoid fertilizer application to surface waters

- Minimize chemical spray drift

- Follow chemical label instructions and laws

- Practice safe chemical storage and disposal

- Use cover crops to control soil erosion

- Protect heavy-use areas

- Use riparian forest buffers as appropriate

- Protect stream banks and shorelines using stabilizing vegetation or structures

- Use field borders and vegetative filter strips to reduce water runoff problems

- Control livestock access to surface water

- Use prescribed grazing practices

- Use legumes

- Appropriately manage cattle mortalities

Soil Testing

Set a testing schedule for each field

- Once every 3 years or per crop rotation Select the proper tools

- Soil probe or auger and bucket Divide fields into uniform sampling areas

- Sample based on soil maps and judgment

- Sample different soil types separately Use the correct sampling technique

- Sample away from fence rows, trees, fertilizer or lime spills, or unusual areas

- Sample to a 6-inch depth Get a composite sample

- Gather at least 15 to 20 cores

- Gather cores at random in zigzag pattern Process the soil sample

- Break up clods

- Dry at room temperature

- Thoroughly mix the dried sample

- Mildly crush the soil

- Place 1 pint of sample in soil sample box

- Label box with 5-digits or less to ID

MSU Extension Soil Testing Laboratory

(662) 325-3313

http://extension.msstate.edu/lawn-and-garden/soil-testing

Box 9610, Mississippi State, MS 39762

Standard tests: pH, available phosphate, potash, calcium, magnesium, sodium, and zinc

Fertilizer Composition

|

Fertilizer Material |

Nitrogen (N) |

Phosphate (P2O5) |

Potash (K2O) |

Sulfur (S) |

|---|---|---|---|---|

|

Ammonium nitrate |

33.5 |

0 |

0 |

0 |

|

Ammonium nitrate and limestone |

20.5 |

0 |

0 |

0 |

|

Anhydrous ammonia |

82 |

0 |

0 |

0 |

|

Urea-ammonium nitrate solution |

28 to 32 |

0 |

0 |

0 |

|

Ammonium sulfate |

21 |

0 |

0 |

24 |

|

Urea |

46 |

0 |

0 |

0 |

|

Ammonium thiosulfate |

12 |

0 |

0 |

26 |

|

Sewage sludge |

4 to 6 |

2.5 to 4 |

0 |

<1 |

|

Ammonium polyphosphate (APP) |

10 |

34 |

0 |

0 |

|

Diammonium phosphate (DAP) |

18 |

46 |

0 |

0 |

|

Monoammonium phosphate (MAP) |

10 to 12 |

50 to 55 |

0 |

0 |

|

Triple superphosphate (TSP) |

0 |

44 to 46 |

0 |

1 |

|

Ground rock phosphate |

0 |

26 to 35; 3% available |

0 |

0 |

|

Basic slag |

0 |

10 to 25 |

0 |

0 |

|

Potassium chloride |

0 |

0 |

60 to 62 |

0 |

|

Potassium nitrate |

13 |

0 |

44 |

0 |

|

Potassium sulfate |

0 |

0 |

48 to 52 |

18 |

|

Sulfate of potash-magnesia |

0 |

0 |

22 |

22 |

|

Poultry litter1 |

2 to 6 |

1.4 to 9 |

1 to 6 |

0 to 0.8 |

1Varies by bird and litter management practice

Adapted from Ball et al. 1999. Forage Crop Pocket Guide. Intl. Plant Nutr. Inst., Norcross, GA.

Forage Herbage Mass

|

Forage Species |

Dry matter, lb/inch/acre |

|

|

Average |

Range |

|

|

Alfalfa or alfalfa-grass mixture |

225 |

75 to 400 |

|

Arrowleaf clover |

200 |

100 to 300 |

|

Bermudagrass |

260 |

150 to 500 |

|

Crimson clover |

200 |

100 to 300 |

|

Native warm-season bunchgrasses |

100 |

50 to 250 |

|

Red clover |

220 |

100 to 300 |

|

Annual ryegrass |

250 |

75 to 400 |

|

Oats, rye, wheat |

150 |

75 to 250 |

|

Tall fescue |

210 |

100 to 350 |

|

Tall fescue with white clover |

190 |

80 to 325 |

Adapted from Ball et. Al. 2007. Southern Forages. 4th ed. Intl. Plant Nutr. Inst., Norcross, GA.

Rotational Stocking Guidelines1

|

|

Target Grazing Height, inches |

||

|---|---|---|---|

|

Crop |

Begin Grazing |

End Grazing2 |

Usual Days Rest |

|

Alfalfa (hay) |

10 to 16 |

3 to 4 |

35 to 40 |

|

Alfalfa (grazing) |

10 to 16 |

2 to 3 |

15 to 30 |

|

Annual ryegrass |

6 to 12 |

3 to 4 |

7 to 15 |

|

Bahiagrass |

6 to 10 |

1 to 2 |

10 to 20 |

|

Bermudagrass |

4 to 8 |

1 to 2 |

7 to 15 |

|

Big bluestem |

15 to 20 |

10 to 12 |

30 to 45 |

|

Clover, white & subterranean3 |

6 to 8 |

1 to 3 |

7 to 15 |

|

Clover, all others3 |

8 to 10 |

3 to 5 |

10 to 20 |

|

Dallisgrass |

6 to 8 |

3 to 4 |

7 to 15 |

|

Eastern gamagrass |

18 to 22 |

10 to 12 |

30 to 45 |

|

Indiangrass |

12 to 16 |

6 to 10 |

30 to 40 |

|

Johnsongrass |

16 to 20 |

8 to 12 |

30 to 40 |

|

Pearl millet |

20 to 24 |

8 to 12 |

10 to 20 |

|

Sericea lespedeza |

8 to 15 |

4 to 6 |

20 to 30 |

|

Small grains |

8 to 12 |

3 to 4 |

7 to 15 |

|

Sorghum (forage) |

20 to 24 |

8 to 12 |

10 to 20 |

|

Sorghum-sudan hybrids |

20 to 24 |

8 to 12 |

10 to 20 |

|

Switchgrass |

18 to 22 |

8 to 12 |

30 to 45 |

|

Tall fescue |

4 to 8 |

2 to 3 |

15 to 30 |

1The more closely pastures are grazed, the longer the rest period needs to be for defoliation-sensitive species.

2The closer a pasture is grazed, the poorer the forage nutritive value will be toward the end of grazing cycle.

3Clovers are typically grown in mixtures with grasses.

Adapted from Ball et al. 1999. Forage Crop Pocket Guide. Intl. Plant Nutr. Inst., Norcross, GA.

Rotational Stocking Benefits

- Increased carrying capacity

- Cattle easier to handle

- Closer observation of cattle

- Better pasture persistence and productivity

- Improved utilization of more forage species

- Less trampling

- Better manure and urine distribution

- Environmental benefits

Forest Harvest Stages

Recommended Harvest Stage for Silage

|

Forage |

Recommended Harvest Stage |

|---|---|

|

Alfalfa |

Bud to early bloom |

|

Bermudagrass (hybrid) |

Height of 15 inches for 1st cutting, 4- to 5-week intervals thereafter |

|

Cool-season grasses |

Boot to early head for 1st cutting, 4- to 6-week intervals thereafter |

|

Forage sorghum |

40 inches or late boot stage |

|

Grain sorghum |

Late milk to late dough stage |

|

Small grains, annual ryegrass |

Boot to early head |

|

Soybeans |

Late bloom and before bottom leaves begin to fall |

|

Summer-annual grasses |

40 inches or boot stage (whichever comes 1st) |

Recommended Harvest Stage for Hay

|

Forage |

Recommended Harvest Stage |

|---|---|

|

Alfalfa |

Bud stage for 1st cutting, 1/10th bloom for later cuttings |

|

Annual lespedeza |

Early bloom and before bottom leaves begin to fall |

|

Bermudagrass (hybrid) |

Height of 15 to 18 inches for 1st cutting, 4- to 5-week intervals thereafter |

|

Big bluestem, indiangrass, switchgrass |

Early head stage |

|

Oats, wheat |

Boot to early head stage |

|

Pearl millet, sudangrass, sorghum-sudan |

Height of 30 to 40 inches |

|

Red, arrowleaf, crimson clovers |

Early bloom |

|

Sericea lespedeza |

Height of 15 to 18 inches |

|

Soybean |

Mid- to full-bloom and before bottom leaves begin to fall |

|

Tall fescue |

Boot to early head stage for 1st cutting, 4- to 6-week intervals thereafter |

|

White clover |

Stage for companion grass |

Adapted from Ball et al. 1999. Forage Crop Pocket Guide. Intl. Plant Nutr. Inst., Norcross, GA.

Forage Dry Matter Percentage

|

Dry matter, % |

Forage description |

|---|---|

|

8 to 15 |

Young, green, succulent (i.e., small grains, tall fescue, annual ryegrass, especially in seedling stages) |

|

15 to 20 |

Young, green leafy grasses in spring or when growth is rapid and succulent; white clover in mature stages; alfalfa in prebud stage |

|

20 to 30 |

Older, slightly brown, or slow-growing plants; headed cool-season grasses; actively growing bermudagrass; alfalfa at 10% bloom |

|

40 to 50 |

Growth that is more than 40% brown; stockpiled growth in winter and dormant grasses; may be stored in an airtight silo or tightly wrapped bales |

|

40 to 80 |

Plants cut for storage; feel slightly damp or pliable, but too wet to bale |

|

80 to 85 |

Hay freshly baled; mold forms if stored below 80% dry matter |

|

85 to 92 |

Hay stored inside after several months; in samples that are air dried in cloth bags, the leaves will break easily when crumbled or twisted |

Adapted from Ball et. Al. 2007. Southern Forages. 4th ed. Intl. Plant Nutr. Inst., Norcross, GA.

Forage Sampling and Quality

Forage Sampling for Laboratory Analysis

- Follow specific directions for the laboratory selected

- Do not use grab samples

- Use a ⅜- to ⅝-inch internal diameter forage probe to core bales

- Keep forage probe cutting edge sharp

- Sample at random from each hay lot (single cutting, field, and maximum quantity of 200 bales)

- Collect ½ to ¾ lb of sample per lot

- Combine at least 20 core samples from each hay lot into one sample for submission

- Sample round bales stored under cover at a 45 degree angle from the top of the bale

- Sample round bales stored outside without cover at a 90 degree angle from the top of the bale

- Sample square bales from the center of their ends

- Uniquely identify each sample

- Protect from heat and direct sunlight

- Include completed sample submission forms and necessary payments

- Package securely and ship promptly

- Ship perishable samples under refrigeration

Forage Quality Terminology

Dry matter (DM)

- % of plant sample remaining after water removed

- 100 - moisture % = dry matter % In vitro digestible dry matter (IVDMD)

- digestibility determined via laboratory test Total digestible nutrients (TDN)

- indicator of forage energy content Crude protein (CP)

- quantity of true protein and non-protein nitrogen present in plant tissue

- nitrogen x 6.25

Neutral detergent fiber (NDF)

- percentage of cell walls or other plant structural material present

- cellulose + hemicellulose + lignin

- only partially digested by animals

- higher NDF associated with lower animal intake

Acid detergent fiber (ADF)

- percentage of highly indigestible plant material

- cellulose + lignin

- higher ADF associated with lower digestibility

Dry matter intake (DMI)

- amount of forage an animal will eat

- estimate based on results from animal feeding trials and measured NDF concentration of a forage

Digestible dry matter (DDM)

- percentage of forage sample which is digestible

- estimate based on results from animal feeding trials and measured ADF concentration of a forage Relative feed value (RFV)

- expression of a forage’s expected intake by animals and its energy value

- index ranking forages on ADF and NDF

- DDM x DMI ÷ 100

- compared to full bloom alfalfa (RFV = 100)

- forage quality increases as RFV increases Relative forage quality (RFQ)

- similar to RFV but uses TDN in place of DDM

- includes digestible fiber, so more representative of animal performance than RFV

- use with all forages except corn silage

Forage Quality Standards by Forage Type

|

Forage Type |

Standard |

Total Digestible Nutrients1 |

Crude Protein1 |

Moisture |

pH |

|---|---|---|---|---|---|

|

Silage2 |

Excellent |

65% or above |

8% or above |

70% or below |

4.2 or below |

|

Good |

60 to 64% |

7 to 8% |

71 to 74% |

4.3 to 4.7 |

|

|

Fair |

55 to 59% |

6 to 7% |

75% and above |

4.8 to 5.1 |

|

|

Poor |

Below 55% |

Below 6% |

75% and above |

5.2 or above |

|

|

Grass Hay3 |

Excellent |

58% or above |

12% or above |

|

|

|

Good |

55 to 57% |

10 to 11% |

|

|

|

|

Fair |

52 to 54% |

8 to 9% |

|

|

|

|

Poor |

Below 52% |

Below 8% |

|

|

|

|

Legume Hay3 |

Excellent |

64% or above |

18% or above |

|

|

|

Good |

60 to 63% |

16 to 17% |

|

|

|

|

Fair |

57 to 59% |

14 to 15% |

|

|

|

|

Poor |

Below 57% |

Below 14% |

|

|

1Dry matter basis.

2Determine silage quality by total digestible nutrients rating. If silage does not meet either crude protein or moisture requirement for quality, lower one standard.

3Determine hay quality by total digestible nutrients rating. If hay does not meet crude protein requirement or is less than 83% dry matter, lower one standard.

General Forage Quality Standards1

|

Quality Standard |

Crude Protein (CP) |

Acid Detergent Fiber (ADF) |

Neutral Detergent Fiber (NDF) |

Digestible Dry Matter (DDM)2 |

Dry Matter Intake (DMI)3 |

Relative Feed Value (RFV)4 |

|---|---|---|---|---|---|---|

|

Prime |

Above 19% |

Below 31% |

Below 40% |

Above 65% |

Above 3.0% |

Above 151 |

|

1 |

17 to 19% |

31 to 35% |

40 to 46% |

62 to 65% |

2.6 to 3.0% |

125 to 151 |

|

2 |

14 to 16% |

36 to 40% |

47 to 53% |

58 to 61% |

2.3 to 2.5% |

103 to 124 |

|

3 |

11 to 13% |

41 to 42% |

54 to 60% |

56 to 57% |

2.0 to 2.2% |

87 to 102 |

|

4 |

8 to 10% |

43 to 45% |

61 to 65% |

53 to 55% |

1.8 to 1.9% |

75 to 86 |

|

5 |

Below 8% |

Above 45% |

Above 65% |

Below 53% |

Below 1.8% |

Below 75 |

1 Dry matter basis; applicable to legume, grass, or grass-legume hay.

2 Digestible dry matter (DDM%) = 88.9 – 0.779 ADF (% of dry matter).

3 Dry matter intake (DMI) = 120 ÷ forage NDF (% of dry matter).

4 Relative feed value (RFV) calculated from DDM x DMI ÷ 1.29. Reference hay of 100 RFV contains 41% ADF and 53% NDF.

Hay Heating Effects

|

Hay Core Temperature1, F° |

Possible Event |

|---|---|

|

120 |

Protein breakdown |

|

140 |

Sugar caramelization |

|

150 to 180 |

Fire (likely) |

1Maximum temperature typically occurs 1 week after baling but can happen up to 3 weeks later.

Adapted from Ball et al. 1999. Forage Crop Pocket Guide. Intl. Plant Nutr. Inst., Norcross, GA.

To reduce risk of hay heating, manage moisture content of hay at baling:

- Large round bales: <18% moisture

- Small square bales: <20% moisture

Forage Intake

Factors Affecting Forage Intake

- animal weight, condition, stage of production, milk production level

- environmental conditions

- forage nutritive value

- pasture herbage mass (available forage)

- amount and type of forage or feed offered

- palatability

- toxic factors

- management

Predicting Hay Intake

Dry matter intake as % of body weight = 120/neutral detergent fiber content of hay

Forage Intake Capacity of Beef Cows1

|

Forage Type and Maturity |

Stage of Production |

Forage Dry Matter Intake Capacity, % of body weight |

|---|---|---|

|

Low quality forage (< 52% total digestible nutrients) |

Non-lactating |

1.8 |

|

Lactating |

2.2 |

|

|

Average quality forage (52 to 59% total digestible nutrients) |

Non-lactating |

2.2 |

|

Lactating |

2.5 |

|

|

High quality forage (> 59% total digestible nutrients) |

Non-lactating |

2.5 |

|

Lactating |

2.7 |

|

|

Lush, growing pasture |

Non-lactating |

2.5 |

|

Lactating |

2.7 |

|

|

Silage |

Non-lactating |

2.5 |

|

Lactating |

2.7 |

1Intake estimates assume protein requirements are met in the total diet. When protein requirements are not met, forage intake will be lower than the table values. Adapted from Hibbard and Thrift, 1992.

Dry Matter Intake Adjustment Factors for Specific Environmental Conditions

|

Environmental Condition |

Dry Matter Intake Adjustment Factor1 |

|---|---|

|

Temperature, degrees Fahrenheit |

|

|

> 95 with no night cooling |

.65 |

|

> 95 with night cooling |

.90 |

|

77 to 95 |

.90 |

|

59 to 77 |

1.00 |

|

41 to 59 |

1.03 |

|

23 to 41 |

1.05 |

|

5 to 23 |

1.07 |

|

< 5 |

1.16 |

|

Mud, inches |

|

|

None |

1.00 |

|

Mild, 3.9 to 7.9 |

.85 |

|

Severe, 11.8 to 23.6 |

.70 |

1Multiply factor by predicted dry matter intake to determine adjusted dry matter intake for the condition.

Adapted from NRC. 1987. Predicting Feed Intake of Food-Producing Animals.

Methods to Minimize Forage Losses

- Use management intensive grazing methods

- Reduce leaf shatter at harvest

- Minimize stored forage contact with soil

- Minimize stored forage exposure to weather

- Use hay feeding equipment designed to reduce trampling and waste

Forage-related and Nutritional Disorders

As-fed to Dry Matter (DM) Conversion As-fed basis = as-received basis = forage/feed including moisture content

Dry matter basis = forage/feed excluding water

lb as-fed consumed x % DM = lb DM consumed

Forage/Feed Nitrate Level Guide for Cattle

|

Nitrate Concentration |

Recommended Management |

|

|---|---|---|

|

0.0 to 0.5% |

0 to 5000 ppm |

Safe to feed |

|

0.5 to 1.0% |

5000 to 10,000 ppm |

Risk to pregnant animals and cattle not accustomed to high nitrate containing forage |

|

1.0 to 2.0% |

10,000 to 20,000 ppm |

Not more than half of the diet |

|

>2.0% |

>20,000 ppm |

Do not feed |

Nitrate concentration conversions: Nitrate-N = nitrate x 0.23 Potassium nitrate = nitrate x 0.14

Parts per million (ppm):

To convert ppm to percent, move the decimal 4 places to the left.

Example: 5,000 ppm = 0.5%

Forage-related Disorders of Cattle

|

Disorder |

Cause |

Signs |

Prevention |

|---|---|---|---|

|

Ergot poisoning (Dallisgrass staggers) |

Consumption of toxin produced by parasitic fungus in the seed heads of bahiagrass, annual ryegrass, small grains, and especially dallisgrass; most common in late summer or fall after wet growing conditions |

Lameness, sloughing of tail switch and hooves, elevated body temperature, increased respiratory rate, increased heart rate |

Clip pastures to limit seed head development and ergot growth; avoid harvesting fields with large quantities of potentially infected seed heads for hay |

|

Fescue toxicosis |

Consumption of alkaloids in toxic-endophyte-infected tall fescue plants |

Rough hair coat, depressed weight gain |

Removal from or dilution of toxic pastures and hay |

|

Grass tetany |

Consumption (especially by lactating cattle) of lush forage containing low levels of magnesium or calcium |

Nervousness, muscle twitching around the face and ears, staggering, reduced feed intake, convulsions, death |

Provide magnesium and calcium supplement to cattle at least 30 days prior to and during grass tetany season |

|

Nitrate poisoning |

Consumption of excessive nitrate from forage (most common in warm-season annual grasses), weeds (especially pigweed), water, or other sources; nitrate is absorbed into red blood cells and combines with hemoglobin to produce a type of hemoglobin that cannot carry oxygen in the blood causing a lack of sufficient oxygen transport to tissues |

Bluish skin discoloration, bluish-brown mucous membranes, labored or rapid breathing, tremors, lack of muscle control, staggering, weakness, diarrhea, frequent urination, dark- to chocolate-colored blood, rapid pulse, abortion, coma, suffocation |

Avoid grazing livestock on heavily nitrogen- fertilized pastures of suspect species during drought or wet conditions through cool, cloudy weather; observe carefully for signs of nitrate poisoning; test forages of concern for nitrate-nitrogen levels |

|

Prussic acid poisoning |

Consumption of prussic acid- containing forage (leaves of johnsongrass, sorghum, sudangrass, sorghum-sudan hybrids, and wild cherry); most likely after frost or drought) |

Excessive salivation, rapid, breathing, muscle spasms, death |

Avoid toxic forages; prussic acid levels in forages deteriorate over time; feed as hay, 3+ weeks after ensiling, or 1+ week after frost |

Nutritional Disorders of Cattle

|

Disorder |

Cause |

Signs |

Prevention |

|---|---|---|---|

|

Acidosis |

Shift from a forage- based diet to a high concentrate-based diet or excessive consumption of fermentable carbohydrates causing low rumen pH |

Slowing or stopping of gut movement, diarrhea, dehydration, weakness, incoordination, gray and foamy manure, poor nutrient absorption, reduced but variable feed intake, decreased performance, heart and lung failure, death |

Limit feed consumption; introduce high-concentrate feeds gradually over 3 to 4 weeks; keep at least 10% roughage in the final diet; feed a combination of grains, feed dry grain with high-moisture grain; feed ionophores |

|

Frothy (feedlot) bloat |

Foam development in rumen from high-grain diet prevents belching and leads to suffocation |

Rapid swelling on left side, display of discomfort (kicking at sides, stomping feet), sudden death |

Slowly adapt cattle from forage-based diets to grain- based diets over a period of at least 3 weeks, manage nutrition of chronic bloaters carefully |

|

Pasture (legume) bloat |

Foam development in rumen from diet with high levels of soluble protein (alfalfa, winter annual grasses, white clover) prevents belching and leads to suffocation |

Rapid swelling on left side, display of discomfort (kicking at sides, stomping feet), sudden death |

Fill cattle on hay before turning out on lush legume or winter-annual grass pastures, feed poloxalene or monensin, manage nutrition of chronic bloaters carefully |

|

Hardware disease |

Sharp, heavy object consumed punctures reticulum wall, diaphragm, and/or heart sac causing damage to and infection of the abdominal cavity, heart sac, or lungs |

Loss of appetite, depression, reluctance to move, arched back, indications of pain, grunting when forced to walk, bloat appearance on upper left side with fluid accumulation on lower right, fluid accumulation in brisket, death |

Keep pastures, paddocks, and feed bunks free of wire, nails, fencing staples, and other sharp objects (even heavy plastic items) that could be swallowed; place magnets on feeding equipment; administer an intraruminal magnet |

Mycotoxins Affecting Cattle

|

Mycotoxin |

Risk Conditions |

Risk Feeds |

Effects on Cattle |

Signs of Toxicosis |

|---|---|---|---|---|

|

Aflatoxin (most common mycotoxin in MS) |

Hot, dry conditions |

Corn, cottonseed, peanuts, sorghum |

Causes cancer, inhibits protein production, suppresses immune system, disrupts rumen function |

Dry muzzle, decreased body temperature, young cattle more susceptible |

|

Fumonisin |

Cool, wet following hot, dry weather |

Corn, particularly screenings |

Damages liver |

Elevated serum liver enzymes, liver lesions |

|

Vomitoxin (Deoxynivalenol, DON) |

Cool, wet conditions |

Wheat, barley, rye, oats |

Inhibits protein production, affects digestive tract and immune system |

No apparent adverse effects at low levels in ruminating cattle |

|

Ochratoxin A |

Hot, dry conditions |

Corn, barley, wheat, rye |

Possibly causes cancer, causes frequent urination leading to kidney damage |

Increased water consumption and urination |

|

Zearalenone (F-2 toxin, giberella toxin) |

Cool, wet conditions |

Corn, wheat, barley, oats |

Produces estrogenic effect |

Infertility, estrous cycle disruptions |

FDA Action Levels for Total Aflatoxins in Livestock Feed

|

Animal Class |

Feed |

FDA Action Level |

|---|---|---|

|

Finishing beef cattle |

Corn and peanut products |

300 ppb |

|

Beef cattle, swine, or poultry |

Cottonseed meal |

300 ppb |

|

Corn and peanut products |

Corn and peanut products |

100 ppb |

|

Immature animals |

Animal feeds and ingredients, excluding cottonseed meal |

20 ppb |

|

Dairy animals or unknown use |

Animal feeds and ingredients |

20 ppb |

Grazing Methods

Continuous stocking is a method of grazing livestock on a specific unit of land where animals have unrestricted and uninterrupted access throughout the time period when grazing is allowed. Set stocking is the practice of allowing a fixed number of animals on a fixed area of land during the time when grazing is allowed.

Continuous stocking with fenced off area during forage surplus growth: Areas can be fenced off from continuous stocking during periods of surplus forage growth to help keep the forage being grazed from becoming overmature. The stockpiled forage can then be either grazed at a later date or harvested for hay. Stockpiling forage (deferred grazing) is where forage is allowed to accumulate for grazing at a later period.

Rotational stocking is a grazing method that utilizes recurring periods of grazing and rest among 2 or more paddocks in a grazing management unit through the period when grazing is allowed.

Strip grazing involves confining animals to an area of grazing land to be grazed in a relatively short period of time, where the paddock size is varied to allow access to a specific land area. Mob grazing is a variation of strip grazing where a large number of animals are grazed on a relatively small number of acres to rapidly remove forage from the paddock. Mob grazing is useful when forage growth needs to be removed prior to sodseeding another forage crop in the same paddock.

Creep grazing is a form of preweaning supplementation of nursing calves. It is the practice of allowing nursing calves to graze areas that their dams cannot access at the same time. This is accomplished through use of a creep gate that the calves can pass through freely but their dams cannot.

Forward creep grazing is a method of creep grazing in which dams and calves rotate through a series of paddocks with calves as first grazers and dams as last grazers. Calves have more opportunity for selectivity than their dams. This is a specific form of forward grazing. Forward grazing (leader-follower, preference-follower, top and bottom grazer, first-last grazing) is a method of utilizing 2 or more groups of animals, usually with different nutritional requirements, to graze sequentially on the same land area.

Greenchop is where green, actively growing forage is chopped mechanically and fed to livestock. This method reduces waste by grazing animals so that more animals can be fed per acre. However, forage selectivity is reduced, and individual animal performance is often lower. Equipment, fuel, and labor costs are higher with this forage harvest method.

Limit grazing is where livestock are maintained on lower quality pasture but allowed to access a higher quality pasture (typically winter annual grass pasture) for a few hours each day or every few days. Waste from trampling is reduced with this method. This method provides good nutrition at relatively low cost as the area needed for high quality pasture is relatively small. Cattle learn to move to and from paddocks with relative ease after a routine is established.

Grazing Formulas

Number of paddocks=days of rest/days of grazing +1

Acres required per paddock = average animal weight x dry matter consumed per animal as % of body weight x number of animals x days on pasture/dry matter available in grazing area x % of dry matter utilized by grazing

Total acres required = number of paddocks x acres required per paddock

Stocking rate = number of animals grazed/total acres grazed

Stocking density = number of animals grazed/paddock size in acres

Body Condition Score (BCS)

- Tool used to evaluate nutritional status

- Body condition (fat cover) indicates the energy reserves of an animal

- Females in thin body condition at calving are slower to rebreed, produce less colostrum, may not have sufficient nutrient reserves for maximum milk production, and are less likely to wean a live calf

- Over-conditioning is expensive and can result in calving problems and lower dry matter intake early in lactation

- Easily evaluated by visual appraisal

- Does not require cattle handling

Recommended body condition scores at calving:

- mature cows: BCS 5

- first-calf heifers: BCS 6

Ideal times to body condition score beef cattle:

- When calves are weaned

- 45 days after weaning

- 90 days prior to calving

- At calving

- At the start of the breeding season

BCS 1 = Emaciated: No palpable fat is detectable over the spinous processes, transverse processes, ribs, or hooks. The tailhead and ribs appear very prominent.

BCS 2 = Poor: Animal is still somewhat emaciated but the tailhead and ribs are less prominent. Individual spinous processes are still sharp to the touch. Some tissue cover is present over the ribs towards the top of the back.

BCS 3 = Thin: Individual ribs including foreribs are easily identified but are not quite as sharp to the touch. Some fat can be felt along the spine and over the tailhead. Some tissue cover is present over the ribs towards the top of the back.

BCS 4 = Borderline: Individual ribs may not be visually obvious. Individual spinous processes can be felt when palpated but feel rounded rather than sharp. Some fat cover is present over the ribs, transverse processes and hooks.

BCS 5 = Moderate: Overall appearance is generally good. Fat cover over ribs feels spongy. Palpable fat cover is present on either side of the tailhead.

BCS 6 = High moderate: A high degree of palpable fat exists over the ribs and around the tailhead. Firm pressure is needed to feel the spinous processes.

BCS 7 = Good: Considerable fat cover is present with a fleshy overall appearance. Fat cover over the ribs and around the tailhead is very spongy. Fat “pones” or “rounds” may be starting to form alongside the tailhead.

BCS 8 = Fat: The animal is very fleshy and appears over-conditioned. Palpation of the spinous processes is near impossible. Large fat deposits are present over the ribs and around the tailhead. Fat pones around the tailhead are obvious.

BCS 9 = Extremely fat: The overall appearance is blocky with extremely wasty and patchy fat cover. The tailhead and hooks are buried in fatty tissue with fat pones protruding. Bone structure is no longer visible and barely palpable. Large fatty deposits may even impair animal mobility.

Nutrient requirements to increase body condition score of beef cows from 4 to 5 during the last 90 days of pregnancy1

|

Animal Description |

Dry Matter Intake |

Diet Nutrient Density |

Daily Nutrients per Animal |

|||||

|---|---|---|---|---|---|---|---|---|

|

Mature BW at body condition score 5, lb |

DMI, lb/day |

DMI, % of BW |

TDN, % DM |

NEm , Mcal/lb |

CP, % DM |

TDN, lb |

NEm , Mcal |

CP, lb |

|

1,000 |

20.5 |

2.1 |

60 |

.59 |

7.7 |

12.3 |

12.1 |

1.57 |

|

1,100 |

22.0 |

2.0 |

60 |

.58 |

7.5 |

13.2 |

12.8 |

1.65 |

|

1,200 |

23.5 |

2.0 |

59 |

.58 |

7.4 |

13.9 |

13.6 |

1.74 |

1BW = shrunk body weight or 96% full body weight, DMI = dry matter intake, TDN = total digestible nutrients, NEm = net energy for maintenance, CP = crude protein, Ca = calcium, P = phosphorus Adapted from NRC, 2000. NRC Nutrient Requirements of Beef Cattle, 7th revised edition.

Nutrient requirements to increase body condition score of non-pregnant beef cows1

|

Animal Description |

Body Condition Score |

Dry Matter Intake |

Diet Nutrient Density |

Daily Nutrients per Animal |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Mature BW at BCS 5, lb |

BCS |

Days to gain 1 BCS |

DMI, lb/day |

DMI, % of BW |

TDN, % DM |

NEm , Mcal/lb |

CP, % DM |

TDN, lb |

NEm , Mcal |

CP, lb |

|

1,000 |

3 |

30 |

18.8 |

1.9 |

64 |

.65 |

6.1 |

12.0 |

12.2 |

1.14 |

|

60 |

17.7 |

1.8 |

57 |

.55 |

6.4 |

10.1 |

9.8 |

1.14 |

||

|

4 |

30 |

20.5 |

2.1 |

66 |

.67 |

5.9 |

13.5 |

13.8 |

1.21 |

|

|

60 |

19.0 |

1.9 |

58 |

.56 |

6.4 |

11.0 |

10.7 |

1.21 |

||

|

1,100 |

3 |

30 |

20.3 |

1.8 |

65 |

.66 |

6.0 |

13.2 |

13.4 |

1.22 |

|

60 |

19.0 |

1.7 |

58 |

.56 |

6.4 |

11.0 |

10.6 |

1.22 |

||

|

4 |

30 |

22.2 |

2.0 |

67 |

.69 |

5.9 |

14.9 |

15.3 |

1.30 |

|

|

60 |

20.4 |

1.9 |

58 |

.57 |

6.4 |

11.8 |

11.6 |

1.30 |

||

|

1,200 |

3 |

30 |

21.0 |

1.8 |

65 |

.69 |

6.2 |

13.7 |

14.5 |

1.30 |

|

60 |

20.3 |

1.7 |

58 |

.56 |

6.4 |

11.8 |

11.3 |

1.30 |

||

|

4 |

30 |

23.5 |

2.0 |

67 |

.68 |

5.9 |

15.7 |

16.0 |

1.38 |

|

|

60 |

21.8 |

1.8 |

58 |

.56 |

6.3 |

12.6 |

12.3 |

1.38 |

||

1BCS = body condition score, DMI = dry matter intake, BW = shrunk body weight or 96% full body weight, TDN = total digestible nutrients, NEm = net energy for maintenance, CP = crude protein

Adapted from NRC, 2000. NRC Nutrient Requirements of Beef Cattle, 7th revised edition.

Beef Cattle Water Intake Estimates

|

Weight, lb |

Water intake estimates, gallons |

|||||

|

Temperature, oF |

||||||

|

40 |

50 |

60 |

70 |

80 |

90 |

|

|

Growing beef calves |

||||||

|

400 |

4.0 |

4.3 |

5.0 |

5.8 |

6.7 |

9.5 |

|

600 |

5.3 |

5.8 |

6.5 |

7.8 |

8.9 |

12.7 |

|

800 |

6.3 |

6.8 |

7.9 |

9.2 |

10.6 |

15.0 |

|

Finishing cattle |

||||||

|

600 |

6.0 |

6.5 |

7.4 |

8.7 |

10.0 |

14.3 |

|

800 |

7.3 |

7.9 |

9.1 |

10.7 |

12.3 |

17.4 |

|

1,000 |

8.7 |

9.4 |

10.8 |

12.6 |

14.5 |

20.6 |

|

Pregnant cows |

||||||

|

9001 |

6.7 |

7.2 |

8.3 |

9.7 |

NA |

NA |

|

Lactating Cows |

||||||

|

900 |

11.4 |

12.6 |

14.5 |

16.9 |

17.9 |

16.2 |

|

Mature bulls |

||||||

|

1,400 |

8.0 |

8.6 |

9.9 |

11.7 |

13.4 |

19.0 |

|

1,600+ |

8.7 |

9.4 |

10.8 |

12.6 |

14.5 |

20.6 |

1NA = not available. Adapted from NRC, 2000. NRC Nutrient Requirements of Beef Cattle,7th rev. ed.

Adequate Water Availability

- adequate number and size of water sources

- do not allow supplies to run low or out

- livestock may go thirsty

- livestock may damage water troughs

- water quality declines

- check daily

Stock Tank Capacity1

|

Circular Type |

Round-end Type |

|||

|---|---|---|---|---|

|

Diameter, ft |

Capacity, gallons |

Width, ft |

Length, ft |

Capacity, gallons |

|

3 |

100 |

2 |

4 |

95 |

|

3 ½ |

140 |

2 |

5 |

120 |

|

4 |

185 |

2 |

6 |

140 |

|

4 ½ |

235 |

2 |

7 |

185 |

|

5 |

290 |

2 |

8 |

195 |

|

5 ½ |

350 |

2 |

10 |

250 |

|

6 |

420 |

3 |

5 |

175 |

|

6 ½ |

495 |

3 |

6 |

220 |

|

7 |

570 |

3 |

7 |

260 |

|

7 ½ |

660 |

3 |

8 |

300 |

|

8 |

750 |

3 |

10 |

385 |

|

9 |

950 |

3 |

12 |

475 |

|

10 |

1170 |

3 |

14 |

560 |

1Height = 2 ft

Adapted from NCBA.2001. IRM Pocket Reference. 1st ed.

Acceptable Drinking Water for Cattle

- pH: 6.5 to 8.0

- ≤3,000 ppm total dissolved solids

- ≤100 ppm nitrate-nitrogen

- <500 mg sulfate per liter (contribute to <0.4% total dietary sulfur on a dry matter basis)

- ≤1 coliform per 10 mL water

- Free of nutrient enrichment, blue-green algae

Cattle Nutrient Requirements

Growing Steer and Heifer Nutrient Requirements: 1,100 lb at Finishing1

|

|

Diet Nutrient Density |

Daily Nutrients/Animal |

||||

|---|---|---|---|---|---|---|

|

Body weight, lb |

ADG, lb |

DMI, lb/day |

TDN, % dry matter |

CP, % dry matter |

TDN, lb |

CP, lb |

|

300 |

0.5 |

7.9 |

54 |

9.2 |

4.3 |

0.73 |

|

1.0 |

8.4 |

59 |

11.4 |

5.0 |

0.95 |

|

|

1.5 |

8.6 |

64 |

13.6 |

5.5 |

1.17 |

|

|

2.0 |

8.6 |

69 |

16.2 |

5.9 |

1.39 |

|

|

2.5 |

8.5 |

75 |

18.9 |

6.4 |

1.61 |

|

|

3.0 |

8.2 |

83 |

22.2 |

6.8 |

1.83 |

|

|

400 |

0.5 |

9.8 |

54 |

8.7 |

5.3 |

0.85 |

|

1.0 |

10.4 |

59 |

10.4 |

6.1 |

1.08 |

|

|

1.5 |

10.7 |

64 |

12.1 |

6.8 |

1.30 |

|

|

2.0 |

10.7 |

69 |

14.1 |

7.4 |

1.51 |

|

|

2.5 |

10.6 |

75 |

16.3 |

8.0 |

1.72 |

|

|

3.0 |

10.2 |

83 |

19.0 |

8.5 |

1.94 |

|

|

500 |

0.5 |

11.6 |

54 |

8.4 |

6.3 |

0.97 |

|

1.0 |

12.2 |

59 |

9.8 |

7.2 |

1.19 |

|

|

1.5 |

12.6 |

64 |

11.2 |

8.1 |

1.41 |

|

|

2.0 |

12.7 |

69 |

12.8 |

8.8 |

1.63 |

|

|

2.5 |

12.5 |

75 |

14.7 |

9.4 |

1.84 |

|

|

3.0 |

12.1 |

83 |

16.9 |

10.0 |

2.05 |

|

|

600 |

0.5 |

13.2 |

54 |

8.2 |

7.1 |

1.08 |

|

1.0 |

14.0 |

59 |

9.4 |

8.3 |

1.31 |

|

|

1.5 |

14.4 |

64 |

10.6 |

9.2 |

1.53 |

|

|

2.0 |

14.6 |

69 |

11.9 |

10.1 |

1.74 |

|

|

2.5 |

14.4 |

75 |

13.6 |

10.8 |

1.95 |

|

|

3.0 |

13.8 |

83 |

15.7 |

11.5 |

2.17 |

|

|

700 |

0.5 |

14.9 |

54 |

8.0 |

8.0 |

1.19 |

|

1.0 |

15.8 |

59 |

9.0 |

9.3 |

1.42 |

|

|

1.5 |

16.2 |

64 |

10.1 |

10.4 |

1.64 |

|

|

2.0 |

16.3 |

69 |

11.4 |

11.2 |

1.85 |

|

|

2.5 |

16.1 |

75 |

12.8 |

12.1 |

2.06 |

|

|

3.0 |

15.5 |

83 |

14.6 |

12.9 |

2.27 |

|

1ADG = average daily gain; DMI = dry matter intake; TDN = total digestible nutrients; CP = crude protein

Adapted from NRC, 2000. NRC Nutrient Requirements of Beef Cattle, 7th revised edition

- Lightweight and early-weaned calves need

- More nutrient dense diets

- Greater % crude protein

- Good source of digestible energy

- Provide acceptable levels of critical nutrients with extra care for stressed calves

- Minimize potential for nutritional disorders

- Keep concentrate level <55% in receiving diets

Growing Steer and Heifer Nutrient Requirements: 1,200 lb at Finishing1

|

|

Diet Nutrient Density |

Daily Nutrients/Animal |

||||

|---|---|---|---|---|---|---|

|

Body weight, lb |

ADG, lb |

DMI, lb/day |

TDN, % dry matter |

CP, % dry matter |

TDN, lb |

CP, lb |

|

300 |

0.5 |

7.8 |

54 |

9.4 |

4.2 |

0.73 |

|

1.0 |

8.3 |

58 |

11.5 |

4.8 |

0.95 |

|

|

1.5 |

8.6 |

63 |

13.7 |

5.4 |

1.17 |

|

|

2.0 |

8.6 |

68 |

16.2 |

5.8 |

1.40 |

|

|

2.5 |

8.6 |

73 |

18.7 |

6.3 |

1.61 |

|

|

3.0 |

8.3 |

80 |

22.0 |

6.6 |

1.83 |

|

|

400 |

0.5 |

9.7 |

54 |

8.8 |

5.2 |

0.85 |

|

1.0 |

10.3 |

58 |

10.4 |

6.0 |

1.07 |

|

|

1.5 |

10.6 |

63 |

12.2 |

6.7 |

1.30 |

|

|

2.0 |

10.7 |

68 |

14.1 |

7.3 |

1.51 |

|

|

2.5 |

10.7 |

73 |

16.1 |

7.8 |

1.72 |

|

|

3.0 |

10.4 |

80 |

18.7 |

8.3 |

1.94 |

|

|

500 |

0.5 |

11.5 |

54 |

8.4 |

6.2 |

0.97 |

|

1.0 |

12.2 |

58 |

9.8 |

7.1 |

1.19 |

|

|

1.5 |

12.6 |

63 |

11.2 |

7.9 |

1.41 |

|

|

2.0 |

12.6 |

68 |

12.9 |

8.6 |

1.63 |

|

|

2.5 |

12.6 |

73 |

14.6 |

9.2 |

1.84 |

|

|

3.0 |

12.2 |

80 |

16.8 |

9.8 |

2.05 |

|

|

600 |

0.5 |

13.2 |

54 |

8.2 |

7.1 |

1.08 |

|

1.0 |

14.0 |

58 |

9.3 |

8.1 |

1.31 |

|

|

1.5 |

14.4 |

63 |

10.6 |

9.1 |

1.52 |

|

|

2.0 |

14.4 |

68 |

12.1 |

9.8 |

1.74 |

|

|

2.5 |

14.4 |

73 |

13.5 |

10.5 |

1.95 |

|

|

3.0 |

14.0 |

80 |

15.4 |

11.2 |

2.16 |

|

|

700 |

0.5 |

14.8 |

54 |

8.0 |

8.0 |

1.18 |

|

1.0 |

15.7 |

58 |

9.0 |

9.1 |

1.42 |

|

|

1.5 |

16.2 |

63 |

10.1 |

10.2 |

1.64 |

|

|

2.0 |

16.3 |

68 |

11.3 |

11.1 |

1.85 |

|

|

2.5 |

16.2 |

73 |

12.7 |

11.8 |

2.05 |

|

|

3.0 |

15.8 |

80 |

14.4 |

12.6 |

2.27 |

|

1ADG = average daily gain; DMI = dry matter intake; TDN = total digestible nutrients; CP = crude protein

Adapted from NRC, 2000. NRC Nutrient Requirements of Beef Cattle, 7th revised edition

- Encourage consumption

- Use very palatable feeds/forages

- Proper feed and water placement

- May prefer dry over wet feeds at first

- Receiving diets

- At least maintenance requirements for protein, vitamins, and minerals when feed consumption is 1.0 to 1.5% of body weight

- Keep fat less than 4% total dietary dry matter

- Non-protein nitrogen is not recommended for calves <600 lb.

- Avoid heat-damaged feeds

Growing Bull Nutrient Requirements: 2,000-lb Mature Weight1,2

|

|

Diet Nutrient Density |

Daily Nutrients/Animal |

||||

|---|---|---|---|---|---|---|

|

Body weight, lb |

ADG, lb |

DMI, lb/day |

TDN, % dry matter |

CP, % dry matter |

TDN, lb |

CP, lb |

|

300 |

0.5 |

8.0 |

55 |

9.1 |

4.4 |

0.73 |

|

1.0 |

8.3 |

58 |

11.4 |

4.8 |

0.95 |

|

|

1.5 |

8.5 |

61 |

13.8 |

5.2 |

1.17 |

|

|

2.0 |