Manure Management on Commercial Layer Operations: Manure Production and Challenges

Poultry production activities have significant effects on virtually all aspects of the environment, including air, water, land/soil, biodiversity, and climate change. The impact may be direct, putting stress on the bird’s ability to maintain homeostasis, or indirect, such as climatic changes that may result in reduced availability and quality of feed ingredients. The animals, feed, and manure constitute potential sources of an animal feeding operation’s environmental footprint (carbon, nitrogen, phosphorus, airborne particulates, and microorganisms). Commercial layer operations are no exception; a variety of housing and manure-handling practices can produce different magnitudes of an environmental footprint (Xin et al., 2011). Poultry production has far-reaching effects on a wide range of natural resources and must be carefully managed, given the increasing scarcity of these resources and the opportunities they provide for other livestock sectors.

Hen manure is a valuable nutrient resource for crops and forage and a feedstock for renewable energy generation; however, if mishandled, it can pose significant environmental burdens for air and water quality as well as require additional energy for processing. Manure management in laying hen facilities can greatly influence ammonia (NH3) emissions (Liang et al., 2005). A variety of manure-handling practices exist in egg production facilities because of different production systems (birds on a littered floor versus cage housing) or management schemes (manure removal frequency or drying method) in either manure belt (MB) or high-rise (HR) housing systems (Xin et al., 2011).

Production, Composition, and Application

Management of livestock manure is made more challenging by the fact that not all animals produce the same quantity or quality of manure. Age makes a difference, as older animals produce more manure than younger animals. Species also makes a difference because different types of animals eat different diets and have different metabolism rates. In addition, within species, there are differences in management practices that can affect manure nutrient content. Variation in nutrient content occurs because all livestock are inefficient to varying levels at processing nutrients. Bedding material type (if present) and manure storage practices can also affect nutrient content.

There is value and benefit to land application of manure. It is an excellent way to recycle nutrients and reduces financial investment on commercial fertilizer. Land application of manure also reduces energy spent creating additional commercial fertilizer. And, when done correctly, manure application benefits the soil and will improve

- organic matter content

- cation exchange capacity

- water-holding ability

- soil structure

- bulk density

- microbe activity

However, there are also risks associated with manure application. Manure may contain pathogens, heavy metals, volatile organic compounds (VOCs), and pharmaceuticals/antibiotics. If mishandled, manure may cause excess nutrients to find their way to ground or surface water through leaching or runoff. Air quality impact may also be a concern, related to the smell of ammonia and sulfur and the release of greenhouse gases (GHGs) such as methane (CH4) and nitrous oxide (N2O).

Manure storage is often required because it is not always possible to apply manure as it is produced. Manure management planning must consider several factors:

- production (yearly/daily output)

- collection (how is it moved/handled)

- storage (liquid versus solid containment)

- treatment

- transfer

- use (on-farm, sold)

Looks can be deceiving, and manure nutrient content can vary greatly. Table 1 describes moisture content and nutrient values from 2,054 poultry litter samples in Arkansas (VanDevender et al., 2004). Table 2 shows nutrient losses from a variety of different manure systems (Fulhage & Pfost, 2002). Management practices can play a huge role, along with diet formulation and phytase use, in the wide variations that can exist in manure moisture and nutrient content. A laboratory analysis is required to know exactly what nutrients are present in manure at what levels. Table 3 lists nutrients from a variety of manure types (Zublena et al., 1990).

Table 1. Poultry litter moisture and nutrient content from 2,054 samples in Arkansas.

|

Moisture content (%) |

N (lb/ton) |

P2O5 (lb/ton) |

K2O (lb/ton) |

|

|---|---|---|---|---|

|

Minimum |

2 |

22 |

18 |

23 |

|

Maximum |

47 |

98 |

96 |

80 |

|

Mean |

23 |

60 |

58 |

52 |

Adapted from VanDevender et al. (2004).

Table 2. Nutrient losses from various manure handling systems.

|

Solid manure system |

N % lost |

P2O5 % lost |

K2O % lost |

|---|---|---|---|

|

Daily scrape and haul |

20–35 |

5–15 |

5–15 |

|

Manure pack |

20–40 |

10–20 |

10–20 |

|

Poultry, deep pit or litter |

25–50 |

5–15 |

5–15 |

|

Solids on open lot |

N % lost |

P2O5 % lost |

K2O % lost |

|---|---|---|---|

|

Scrape once/year |

40–55 |

20–40 |

30–50 |

|

Daily scrape and haul |

20–35 |

10–20 |

15–25 |

|

Separated solids, 90 d storage |

30 |

10–20 |

10–20 |

|

Liquid manure system |

N % lost |

P2O5 % lost |

K2O % lost |

|---|---|---|---|

|

Anaerobic pit |

15–30 |

5–20 |

5–20 |

|

Aboveground storage |

10–30 |

5–15 |

5–15 |

|

Manure basin or runoff pond, 120–180 d storage |

20–40 |

5–50 |

5–50 |

|

Liquid, lagoon |

70–85 |

50–80 |

30–80 |

|

Lagoon, 365 d storage |

90 |

50–80 |

30–80 |

Adapted from Fulhage and Pfost (2002).

Table 3. Secondary and micronutrients in various poultry manures.

|

Layer (lb/ton) |

Ca |

Mg |

S |

Na |

Fe |

Mn |

B |

Mo |

Zn |

Cu |

|---|---|---|---|---|---|---|---|---|---|---|

|

Under-cage scraped |

43.0 |

6.1 |

7.1 |

4.5 |

0.5 |

0.27 |

0.05 |

<0.01 |

0.32 |

0.04 |

|

High-rise stored |

86.0 |

6.0 |

8.8 |

5.0 |

1.8 |

0.52 |

0.05 |

<0.01 |

0.37 |

0.04 |

|

Broiler litter (lb/ton) |

Ca |

Mg |

S |

Na |

Fe |

Mn |

B |

Mo |

Zn |

Cu |

|---|---|---|---|---|---|---|---|---|---|---|

|

Broiler house |

41.0 |

8.0 |

15.0 |

13.0 |

1.3 |

0.67 |

0.05 |

<0.01 |

0.63 |

0.45 |

|

Roaster house |

43.0 |

8.5 |

14.0 |

13.0 |

1.6 |

0.74 |

0.05 |

<0.01 |

0.68 |

0.51 |

|

Breeder house |

94.0 |

6.8 |

8.5 |

8.6 |

1.3 |

0.57 |

0.04 |

<0.01 |

0.52 |

0.21 |

|

Stacking shed |

54.0 |

8.0 |

12.0 |

6.2 |

1.5 |

0.59 |

0.04 |

<0.01 |

0.55 |

0.27 |

|

Turkey litter (lb/ton) |

Ca |

Mg |

S |

Na |

Fe |

Mn |

B |

Mo |

Zn |

Cu |

|---|---|---|---|---|---|---|---|---|---|---|

|

Brooder house |

28.0 |

5.7 |

7.6 |

5.9 |

1.4 |

0.52 |

0.05 |

<0.01 |

0.46 |

0.36 |

|

Grower house |

42.0 |

7.0 |

10.0 |

8.4 |

1.3 |

0.65 |

0.05 |

<0.01 |

0.64 |

0.51 |

|

Stacking shed |

42.0 |

6.8 |

9.5 |

6.4 |

1.5 |

0.62 |

0.05 |

<0.01 |

0.56 |

0.34 |

|

Layer (lb/1000 gal) |

Ca |

Mg |

S |

Na |

Fe |

Mn |

B |

Mo |

Zn |

Cu |

|---|---|---|---|---|---|---|---|---|---|---|

|

Liquid slurry |

35.0 |

6.8 |

8.2 |

5.3 |

2.9 |

0.42 |

0.04 |

0.02 |

0.43 |

0.08 |

|

Lagoon sludge |

71.0 |

7.2 |

12.0 |

4.2 |

2.2 |

2.30 |

0.08 |

0.01 |

0.80 |

0.17 |

|

Layer (lb/acre-inch) |

Ca |

Mg |

S |

Na |

Fe |

Mn |

B |

Mo |

Zn |

Cu |

|---|---|---|---|---|---|---|---|---|---|---|

|

Lagoon liquid |

25.0 |

7.4 |

52.0 |

51.0 |

2.0 |

0.24 |

0.4 |

0.02 |

0.70 |

0.19 |

Adapted from Zublena et al. (1990).

Losses of nitrogen (N), phosphorus (P2O5), and potassium (K2O) can occur while manure is in storage. Most of the nitrogen loss is through volatilization as ammonia (NH3) gas, from conversion of either ammonium or urea to ammonia. Phosphorus and potassium losses during storage are relatively low and are mainly a result of handling practices. In addition, phosphorus and potassium do not become gases and are commonly lost as liquid or solid runoff, windblown dust, etc. Much of phosphorus losses in liquid lagoons is the result of the settling of solids. The nutrient may not be present in the liquid, but it is still in the sludge at the bottom of the lagoon.

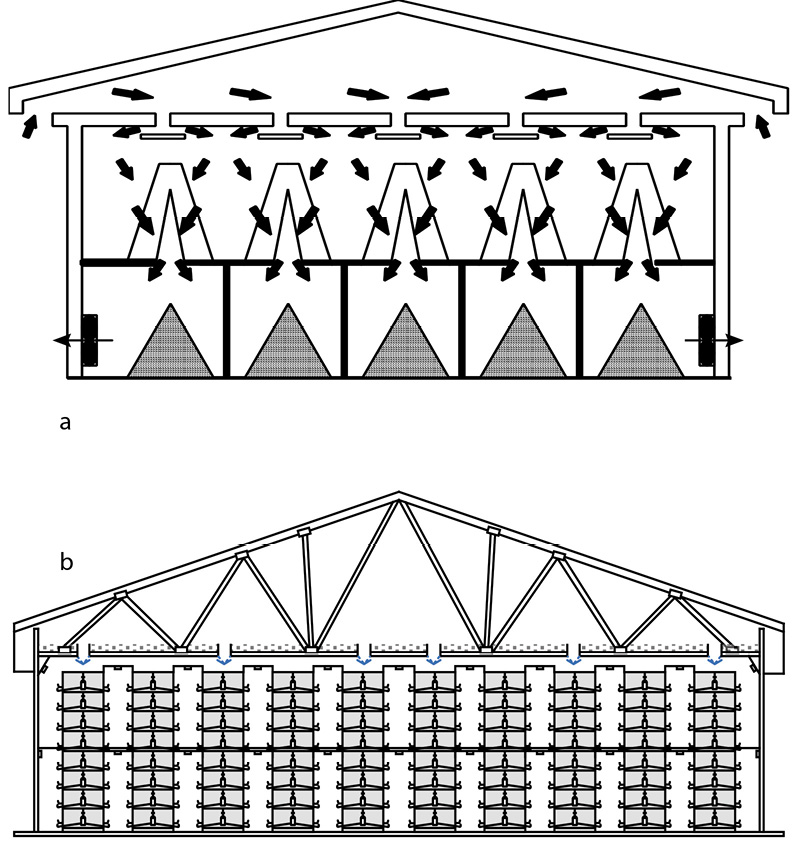

In cage layer systems today, the houses are commonly either high-rise (HR) or manure belt (MB) style (Figure 1). However, in the southern U.S., lagoon systems are still found on many older operations (Figure 2). In the U.S., 70 percent of cage layer houses are HR and 30 percent MB, although new houses typically incorporate the MB style (Xin et al., 2011).

In HR systems, manure either drops into a storage area beneath the cages or falls onto dropping boards that are periodically scraped (four to six times daily), dropping the manure into storage below the cages (Xin et al., 2011). In each system, manure drying, for the most part, is done via ventilation air while in storage. Warm ventilation air passes through the hen and cage area and is directed to flow over the manure surface, providing some level of drying. The ventilation system prevents most of the ammonia in the manure storage level from rising to the hen level by maintaining a pressure gradient between the two levels that improves bird-level air quality. The lower-level manure storage area typically has space to store manure for up to a year, although some operations remove the manure more frequently.

In MB housing, fresh manure (about 75 percent moisture content) drops onto a belt beneath each cage row. Manure on the belt dries naturally through normal ventilation or via a forced-air stream directed under the cages through an air duct over the manure surface. Manure is conveyed via the belts under the cages to one end of the house, where another belt carries it outside for removal to an on- or off-farm storage or composting facility or possibly directly to land application. Depending on the system, manure removal may occur daily, semi-weekly, or weekly.

Laying hen manure has traditionally been treated as a valuable byproduct of egg production and used to recycle nitrogen, phosphorus, and potassium back to the land. In the past, environmental aspects of poultry manure management have focused mainly on water quality. It is well known that manure application can be a contributing nonpoint source of nitrogen and phosphorus to downstream waters through surface pathways (Heathman et al., 1995; Soupir et al., 2006). In the Upper Midwest, nitrate-nitrogen primarily enters waters through subsurface leaching, while the majority of phosphorus export is thought to be associated with surface runoff and sediment (Hoover et al., 2019). Long-term poultry manure application benefits crop yield, soil health, and farm economics (Hoover et al., 2019). Manure-amended soils have greater particulate organic matter, which has been reported to reduce soil erosion, increase infiltration, and increase water-holding capacity.

However, over a 20-year study period, repeated manure application led to accumulated topsoil (10–30 cm) phosphorus (Hoover et al., 2019). Concerns with phosphorus losses may be reduced by applying manure at lower nitrogen rates and supplementing with chemical nitrogen fertilizers. Nitrogen is a key element in animal manure and has been the focus of study in manure management and environmental control for many years (Yang et al., 2000). Ammonia volatilization has become a critical environmental concern for the poultry industry. Controlling ammonia loss is especially difficult in poultry manure because the nitrogen is more concentrated than in other agricultural manure or sewage sludge (Logsdon, 1989).

Challenges

Current and emerging commercial layer operations involve varieties of housing and manure-handling practices with varying environmental footprints. The hens, feed, and manure are potential sources of an operation’s overall environmental footprint (carbon, nitrogen, phosphorus, dust, and microorganisms). Production and housing systems have varying abilities to provide the appropriate microenvironments to the hens, and different effects on the environment. The impact of these microenvironments on ecological systems may result from direct release of airborne constituents into the atmosphere, direct runoff to water bodies, leaching to groundwater, or indirect deposition of airborne particles into water bodies.

Manure characteristics and handling practices impact dust, odor, and aerial transport. Different production systems (HR, MB, non-cage/aviary, bedding versus no bedding) use different handling practices. Non-cage systems usually have some type of bedding material on the floor. Bedding material will alter the physical and nutrient properties of the manure and the litter. Even though hen manure is a valuable nutrient resource for crops and a feedstock for renewable energy, its handling can pose significant environmental burdens for both air and water quality unless proper management practices are followed.

MB cage systems, on a per-hen basis, are roughly 50 percent higher in capital costs than their HR counterparts but offer several benefits over HR systems (Xin et al., 2011). Manure removal is less labor-intensive, although conveyor belt maintenance is critical to success. MB systems generally have better indoor air quality, particularly where ammonia and dust levels are concerned (Green et al., 2009). Frequent manure removal from MB houses also results in lower ammonia emissions, compared to HR houses (Liang et al., 2005). Ammonia emissions from HR houses are higher than MB houses because of a warmer in-house environment for HR houses and manure pile characteristics. To further address the issue, dietary manipulation is an ongoing research area as the cage layer industry continually strives to reduce ammonia emissions. Manure removal is more labor intensive from HR houses but occurs less frequently (often once per year, usually after crop harvest in the fall).

In litter-floor housing systems, manure collects on a litter floor covered with bedding material (shavings, sawdust, etc.) and is removed between flocks. How litter is managed affects ammonia and particulate matter concentrations. Ventilation rates are often lower because of a lower stocking density in this type housing system. Ammonia levels are often higher and the temperature lower than in cage systems. The presence of bedding material and manure on the floor means greater dust concentrations and emissions compared to either MB or HR cage systems.

For free-range systems, most manure is excreted directly onto pasture and not collected or stored, making pasture management critical to success of free-range systems. Soil testing and rotational grazing are critical for forage quality and nutrient management. Phosphorus buildup will be a key concern as cattle grazing pasture return 80 percent of the phosphorus consumed in forage back to the pasture. For systems that collect or store manure or litter, the stored material is land applied periodically. Analyses that provide accurate nutrient profiles of both soil and manure/litter are necessary to determine proper land application rates.

Summary

Hen manure from commercial layer operations is a valuable nutrient resource for crops and forage, but, without proper management, its production and handling can pose significant air and water quality challenges. Differences in animal age and species affect manure quantity and quality. Land application of manure nutrients has both benefits and risks. Manure storage is a common practice, and producers must limit nutrient losses while manure is in storage. While hen manure is a valuable byproduct of egg production, it can be an environmental burden and contribute non-point source nutrients such as nitrogen and phosphorus to ground and surface water. Manure characteristics and handling practices determine nutrient content. Manure and soil analyses are vital pieces to every nutrient management plan and are the only way to accurately determine correct manure application rates and protect the environment.

References

Fulhage, C. D., and D. L. Pfost. 2002. Fertilizer nutrients in livestock and poultry manure. University of Missouri Cooperative Extension Bulletin EQ351.

Green, A. R., I. Wesley, D. W. Trampel, and H. Xin. 2009. Air quality and hen health status in three types of commercial laying hen houses. J. Appl. Poult. Res. 18:605–621.

Heathman, G. C., A. N. Sharpley, S. J. Smith, and J. S. Robinson. 1995. Land application of poultry litter and water quality in Oklahoma, U.S.A. Fert. Res. 40:165–173.

Hoover, N. L., J. Y. Law, L. A. M. Long, R. S. Kanwar, and M. L. Soupir. 2019. Long-term impact of poultry manure on crop yield, soil and water quality, and crop revenue. J. Environ. Manage. 252:109582.

Liang, Y., H. Xin, E. F. Wheeler, et al. 2005. Ammonia emissions from U.S. laying hen houses in Iowa and Pennsylvania. Trans. ASAE 48(5):1927–1941.

Logsdon, G. 1989. Ammonia troubles at egg factories. J. BioCycle 30(2):62–63.

Soupir, M. L., S. Mostaghimi, and E. R. Yagow. 2006. Nutrient transport from livestock manure applied to pastureland using phosphorus-based management strategies. J. Environ. Qual. 35:1269–1278.

VanDevender, K., J. Langston, and M. Daniels. 2004. Utilizing dry poultry litter: An overview. University of Arkansas Cooperative Extension Publ. No. FSA8000.

Xin, H., R. S. Gates, A. R. Green, F. M. Mitloehner, P. A. Moore Jr., and C. M. Wathes. 2011. Environmental impacts and sustainability of egg production systems. Poult. Sci. 90:263–277.

Yang, P., J. C. Lorimor, and H. Xin 2000. Nitrogen losses from laying hen manure in commercial high-rise layer facilities. Trans ASAE 43(6):1771–1780.

Zublena, J. P., J. C. Barker, and T. A. Carter. 1990. Soil facts: Poultry manure as a fertilizer source. North Carolina Extension Service Pub. AG-439-5.

Publication 3719 (POD-10-21)

By Tom Tabler, PhD, Extension Professor, MSU Department of Poultry Science; Yi Liang, PhD, Associate Professor, Biological and Agricultural Engineering Department/Center of Excellence for Poultry Science, University of Arkansas; Jonathan Moon, Poultry Operations Coordinator, MSU Poultry Science; and Jessica Wells, PhD, Assistant Clinical/Extension Professor, MSU Poultry Science.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.