How Do Log Truck Drivers Receive Payment?

Forestry is a large business in the southeastern United States, and a vital component of that business is regular harvesting to capture the growth, yield, and value of the trees. These harvests include thinnings, partial cuttings (e.g., uneven-aged group or individual tree selection), and clearcuts. Forest harvesting, or logging, is extremely important to the fiber supply chain, allowing landowners to conduct management on their property and receive financial compensation for their capital investment. Harvesting also provides fiber to processing facilities that convert the raw woody resource into products like paper, boxes, cartons, lumber, plywood, flooring, among many other useful everyday items.

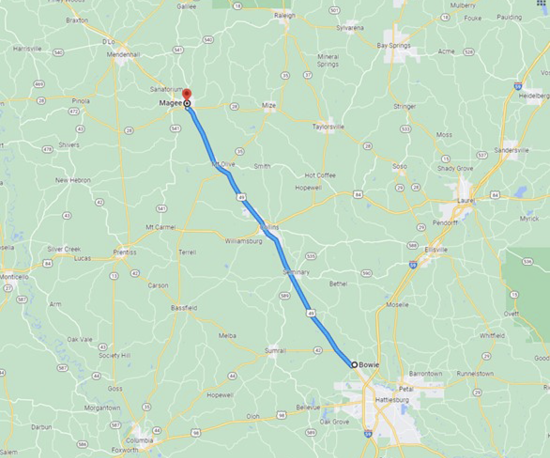

Figure 1. For many log truck driving compensation approaches, compensation is calculated based on the miles driven when loaded (top) and the weight of that load. This is what is meant by loaded miles in Equation 1. More revenue is received for heavier loads transported greater distances. Thus, for the return trip when the truck is unloaded (bottom), no payment is received for those driven miles.

Most forest harvesting operations involve the following:

- felling the trees,

- transporting (i.e., skidding) those trees to a central processing location,

- processing the trees (includes delimbing and removal of tops and other non-merchantable portions),

- merchandizing the stems into product classes to optimize the fiber uses for maximum financial return

The trees are then transported to a processing facility, usually a mill. The hauling and transport component, or the trucking component, is vital to the forest harvesting process.

Many loggers will tell you the most expensive component of harvesting operations is trucking. Several assessments and studies have also shown this to be true (e.g., Conrad 2018, Conrad et al. 2018, McConnell 2020, Conrad 2021). This is particularly true in recent years as truck insurance and diesel fuel costs have been rising at rapid rates. Additionally, the financial difficulties associated with trucking increase with lower value wood products (e.g., hauling pulpwood versus hauling sawlogs). Many foresters, landowners, and loggers-particularly newer loggers-may wonder about the different ways that log truck drivers receive compensation. Additionally, it is important to understand the advantages and disadvantages of each compensation method to better grasp how various aspects of the wood supply chain may impact driver salaries, and perhaps forest landowner stumpage values.

Before describing how log truck drivers are paid, it is important to know how mills pay their suppliers for timber hauled to their mill. Some mills may simply pay a rate per ton of wood delivered, commonly referred to as a delivered price; especially if most deliveries are hauled a relatively short distance. Under this approach, the difference between the delivered price and stumpage price (the price paid to the landowner for their trees) must cover the costs of the log truck, its fuel, maintenance, other operational costs, the log truck driver salary, and all other expenses associated with timber harvesting (e.g. the feller-buncher, skidder, loader, among other expenses).

More commonly, mills pay for hauling with a haul rate that is calculated per ton per loaded mile ($/ton/loaded mile; see Figure 1 and the Appendix). Under this approach, this payment is designed to cover the costs of owning and operating the log truck, including wages and benefits for the truck driver. There is typically a minimum haul distance, often 40 miles, and the log truck owner is paid this rate for deliveries at distances up to the minimum haul distance. The minimum haul distance does vary depending on local market conditions. Currently in Mississippi, a common minimum haul distance is 50 miles. In Georgia, a common minimum haul distance is 40 miles.

The minimum haul distance is used to compensate the log truck owner for the disproportionate amount of time spent loading and unloading on short hauls. On longer hauls, the log truck owner receives the minimum haul rate multiplied by the minimum haul distance, plus an incremental haul rate multiplied by the incremental haul distance (Equation 1). The incremental haul distance is the number of miles during a particular haul in excess of the minimum haul distance. The incremental haul rate may be the same, higher than, or less than the minimum haul rate.

Mill Payment for Timber Transportation ($) =

Tons delivered x Minimum Haul Distance (loaded miles)

x

Minimum Haul Rate ($/ton/loaded mile) +

Tons Delivered x Incremental Haul Distance (loaded miles)

x

Incremental Haul Rate ($/ton/loaded mile)

Within Equation 1, loaded refers to the condition when the trailer contains logs (Figure 1). When using the $/ton/loaded mile compensation approach, the driver only receives payment when the truck is loaded. Thus, for the return trip when the truck is unloaded and empty, no payment is received for those driven miles.

Log Truck Driver Classifications

Prior to describing the seven ways of compensating drivers that we are familiar with, we should review the different classifications of log truck drivers. The different classifications can impact the applicability of various compensation methods to their situation.

Many log truck drivers are employed directly by a logging company. Generally, the company pays for the truck and trailer (and other necessary accessories), insurance for the truck and trailer, maintenance, fuel, training, wages, and benefits to the driver such as healthcare, vacation time, etc. Hence, the driver hauls exclusively for that company, unless contracted out to haul for another company. For the most part, the majority of these drivers work for independent logging contractors and operations. These logging contractors and operations can vary substantially in size in terms of the amount of equipment owned by the company and the amount of acreage or volume harvested annually. However, in addition to the independent logging companies, there are still some drivers that may work for mills and for logging crews paid by the mills. There are also smaller-scale log trucking companies that drivers may work for. These log trucking companies are not directly involved in the actual felling, processing, and loading of the trees and logs.

Secondly, many drivers are independent contract drivers, often referred to as independent owner-operators. In most cases, these self-employed drivers pay for the truck and trailer (and other necessary accessories such as straps or chains, etc.), insurance for the truck and trailer, maintenance, fuel, training, salary, benefits such as health insurance, retirement, etc. In some cases, the owner-operator only owns the truck (or cab or tractor), and thus the contractor (the driver) uses the contractee’s (e.g., logger’s) trailer. For this publication, we concentrate on the situations where the owner-operator (the driver/contractor) owns both the truck and trailer.

Thirdly, something that is relatively new, is that some drivers now work for large scale, commercial companies that are not involved directly with the harvesting operation. These companies are contracted exclusively to transport the unprocessed resource from harvest sites to mills. These companies are also involved in the over-the-road, long-haul, or large-scale and long-distance commercial transportation of materials. For example, JB Hunt Company currently provides timber transportation services to logging businesses. As mentioned, as insurance and diesel fuel continue to increase in price, large scale companies that achieve “economies of scale” to reduce overall costs of operations by introducing efficiencies into the system may grow in importance over time.

Approaches to Driver Compensation

Below are seven approaches or ways that log truck drivers are compensated:

Approach 1: By the Load

Many truck drivers are compensated by the load. For each load of unprocessed products delivered to a mill they receive a fixed rate. For the most part, the value of the timber (e.g., pulpwood versus sawtimber) doesn’t impact wages. There are two differing variations:

1A. Drivers that are employed by the log truck owner are paid a rate per load to compensate them for their time and effort. The payment does not cover costs for fuel, truck and trailer payments, or insurance, which are the responsibility of the truck owner (the employer). The going rate is around $75 per load, but can be greater depending on many factors, one of which is haul distance.

1B. An independent owner-operator driver, that owns the truck and trailer, will receive a higher rate because they themselves are responsible for maintenance, insurance, fuel, etc. Currently, a going rate is around $240 per load, but can be greater depending on many factors. Under this system, driver wages are the profit that is left over after truck and trailer maintenance, fuel, truck and trailer payments, and other expenses are covered. An owner-operator is not guaranteed a profit and may lose money in some cases. There are some slight variations to these two general categories, mainly being bonuses for distance per haul and the number of daily hauls.

Approach 2: Per Ton-mile

Many truck drivers are paid per ton per loaded mile ($/ton/loaded mile). This compensation only applies when the trailer is loaded with unprocessed products and heading to the mill (Figure 1), hence the driver is not directly compensated for the return trip from the mill. With this approach, a driver receives revenue not only for weight (i.e., the tons), but also the distance (miles). Thus, more revenue is received for heavier loads transported greater distances.

Under this approach, the number of daily loads is not an exclusive factor such as with Approach 1. For the most part, the value of the timber (e.g., pulpwood versus sawtimber) doesn’t impact driver compensation. For drivers employed by a logger and who do not own their own tractor-trailer, going rates vary from around $0.05 to $0.09 per ton per loaded mile with a minimum haul distance of 40 miles or 50 miles. Thus, the driver is paid for driving 40 or 50 miles (or another minimum haul distance) even if the haul distance is shorter than 40 or 50 miles. The minimum haul distance is designed to ensure that drivers receive sufficient compensation on short hauls when loading and unloading time represent a significant percentage of the driver’s time.

If the actual haul distance exceeds the minimum haul distance, then the driver is paid an incremental haul rate for the distance traveled beyond the minimum haul distance. The incremental haul rate may be the same, greater than, or less than the minimum haul distance rate. With this system, the driver is compensated in the same way that the log truck owner is paid by the mill. The log truck owner keeps a portion of the mill payment to cover fuel, insurance, truck payments, profit, etc. and pays the driver a portion of the mill’s haul rate for their services.

Owner-operators (who own both the truck and trailer) typically receive the entire haul rate paid by the mill and must use the haul rate to cover fuel, maintenance, truck payments, in addition to paying themselves. For owner-operators, going rates near the end of 2022 vary from around $0.16 to $0.22 per ton per loaded mile.

Approach 3: Percentage of Revenue

Another common compensation approach is to pay the driver a percentage of the revenue generated by the truck. With this approach, the driver receives a percentage of the revenues of delivered unprocessed products. This approach is similar to receiving compensation per ton per loaded mile as described in Approach 2, except the amount received by the driver is linked directly to the haul rate paid by the mill rather than being based on an independent negotiation with the logger. Thus, when the mill increases the haul rate, the driver also automatically receives a raise, and the raise is not dependent on the loggers discretion. This approach generally applies to employees, not owner-operators.

Approach 4: Per Ton or Board Foot

Many drivers are paid per ton or per board foot of timber delivered. Associated with this approach is some minimum haul distance; the driver often receives additional compensation per ton (or board foot) when loaded if the haul distance exceeds the minimum distance. For drivers employed by a logger and who do not own their own tractor-trailer, going rates today are from around $1.50 to $2.00 per ton for employees depending on the location and the minimum haul distance.

Higher rates would be paid to owner-operators (who own both the truck and trailer) to cover fuel, maintenance, truck payments, and other expenses. For owner-operators, who own both the truck and trailer, current going rates are around $8.00 to $12.50 per ton.

Approach 5: Salary

Some drivers receive an annual salary. This system only applies to drivers that are employees, not owner-operators. Regardless of the haul tonnage and distance the driver receives the same compensation. This approach may reduce incentives for risky driving behavior (e.g., speeding, deferred maintenance, driving more hours than allowed by law, etc.) because the driver’s compensation is not determined by the amount of wood hauled or miles traveled.

Approach 6: Hourly Wage

Some drivers are paid by the hour and not a fixed salary. This approach applies to employees, not owner-operators. The driver receives the same compensation regardless of the haul tonnage and distance. Like receiving a salary, this approach may reduce incentives for speeding and deferred maintenance, but it does not remove the incentive to work more hours than allowed by law.

This is potentially beneficial to the employer, if work is sporadic and the driver is not needed on a consistent basis. It could be beneficial to the driver as well, since he or she receives more compensation when more hours are worked. Obviously, there are some disadvantages from both perspectives. How does the employer know the driver is working efficiently? The driver would receive reduced annual compensation relative to some of the other approaches as a result of underutilization. In some cases, drivers receive an hourly wage plus some percentage of gross revenue. This could be beneficial to both parties, since the driver may be more efficient, helping to ensure the employer receives adequate compensation for the salary. Essentially, the driver will want to be more efficient to receive their bonus.

Approach 7: Per Mile

Other drivers are paid by the mile. This approach is best when a consistent weight can be hauled on each trip. This approach reduces incentives for overloading. This approach could be used for employees as well as owner-operators (at a higher rate per mile).

Important Factors Impacting the Amount of Revenue Received

It is important for drivers, log truck owners, loggers, and mills to understand how variables such as loading time, unloading time, and haul distance affect driver compensation. For illustrative purposes, four hauling scenarios of different possible conditions are presented in Tables 1 and 2, along with associated log truck driver compensation amounts given the compensation approach.

For example, on short hauls with efficient loading and unloading, compensation can be quite favorable to the driver when he or she is paid based on production (Tables 1 and 2). When there are delays in production, such as long waiting times at harvest sites or breakdowns, being compensated by the hour or receiving a salary may be better than being paid based on production. At some mills during certain times of day, trucks can be unloaded within 15 minutes of arriving; while at other times of the day or other mills, trucks may wait as long as 2 to 3 hours before being unloaded. Likewise, production-based systems that do not adjust based on mileage can be problematic for drivers on long hauls.

For Scenarios 1, 2, and 3, around 2.3, 3.3, and 3.7 hours are spent per load, respectively. However, for Scenario 4, around 4.7 hours is spent per load. Sixty minutes waiting to be loaded at the logging site, given an average driving speed of 45 miles per hour, 80 minutes is spent driving the 60 miles to the mill, another hour is spent for unloading, and then another 80 minutes is spent on the return trip when empty. Thus, waiting times can be critical to the amount of revenues received. Additionally, the condition of roads and the road type can also have a large impact on driver compensation by reducing the average driving speed both to the mill and during the return trip.

Payload, or the amount of raw woody unprocessed product during a specific haul from the harvesting site to the mill, can also affect driver compensation under several of the compensation methods. Payload almost always affects compensation for the log truck owner, regardless of the type of owner. For the approaches that directly compensate drivers based on payload (e.g., tons or board feet), failing to achieve maximum legal weight reduces driver compensation significantly (Tables 3 and 4). Payment based on payload creates an incentive for illegal overloading. Payloads beyond the legal limit will increase driver compensation, but overloading can be unsafe and may result in fines, some of which can be significant depending on the situation.

At the time of publication, fuel prices are relatively high compared to historical prices, and insurance premiums are continuing to increase for log truck owners. Log truck owners may need to pay their drivers a lower haul rate or salary, or forgo a planned raise. Owner-operators may be unable to sustain themselves without higher haul rates.

In addition, inflation can create substantial problems. Inflation can increase costs of parts, tires, and mechanic rates. Truck owners must either be willing to accept reduced profits (or even losses) or attempt to “pass” these costs on to others. If employing others, one way is through reduced compensation to drivers. Another option is to defer maintenance. This is especially problematic because it may increase costs over the long term and lead to safety violations. As newer model vehicles continue to increase in price, many log truck owners choose to operate older vehicle models to haul wood. This could lead to some issues with dependability and maintenance costs, and may make it more difficult to recruit and retain the best drivers.

There are small nuances or adjustments to each approach depending on the companies involved. Bonuses, or additional compensation, can be extremely beneficial to the driver and the employer. Bonuses can help to ensure that the driver is working efficiently, and if the driver is employed directly by the employer, that the driver is taking care of the vehicles. When determining compensation, it is important to ensure that the driver’s financial incentives are aligned with the company’s interests. The goal should be to incentivize safety and efficiency. Compensation schemes that encourage overloading, speeding, or exceeding state and federal hours of service regulations inevitably backfire and lead to higher costs in the long run.

|

Approach |

Payment Rate |

Scenario 1 |

Scenario 2 |

Scenario 3 |

Scenario 4 |

|---|---|---|---|---|---|

|

A1 |

$84/load |

$36.00/hr |

$25.20/hr |

$22.91/hr |

$18.00/hr |

|

A2 |

$0.07/ton/loaded mile |

$36.00/hr |

$25.20/hr |

$34.36/hr |

$27.00/hr |

|

A3 |

41.2% of $0.17/ton/loaded mile |

$36.00/hr |

$25.20/hr |

$34.36/hr |

$27.00/hr |

|

A4 |

$2.80/ton |

$36.00/hr |

$25.20/hr |

$21.91/hr |

$18.00/hr |

|

A55 |

$50,000/yr |

$21.43/hr |

$20.00/hr |

$18.18/hr |

$21.43/hr |

|

A6 |

$25.00/hr |

$25.00/hr |

$25.00/hr |

$25.00/hr |

$25.00/hr |

|

A7 |

$2.10/loaded mile |

$36.00/hr |

$25.20/hr |

$34.36/hr |

$27.00/hr |

Scenario 1 is 30 minutes loading time, 30 minutes unloading time, 30-mile haul1, 2; Scenario 2 is 60 minutes loading time, 60 minutes unloading time, 30-mile haul1, 2; Scenario 3 is 30 minutes loading time, 30 minutes unloading time, 60-mile haul1, 3; Scenario 4 is 60 minutes loading time, 60 minutes unloading time, 60-mile haul1, 3.

All scenarios assume 30 tons per load (payload) and a pay rate based on a 40-mile minimum haul distance4. An average travel speed of 45 miles per hour was assumed to account for stops at stop signs and stop lights and slow travel speed on unpaved roads.

|

Approach |

Payment Rate |

Scenario 1 |

Scenario 2 |

Scenario 3 |

Scenario 4 |

|---|---|---|---|---|---|

|

A1 |

$240/load |

$102.86/hr |

$72.00/hr |

$65.45/hr |

$51.43/hr |

|

A2 |

$0.17/ton/loaded mile |

$87.43/hr |

$61.20/hr |

$83.45/hr |

$65.57/hr |

|

A4 |

$10.00/ton |

$128.57/hr |

$90.00/hr |

$81.82/hr |

$64.29/hr |

|

A7 |

$7.00/loaded mile |

$120.00/hr |

$84.00/hr |

$114.55/hr |

$90.00/hr |

Although the hourly wage is greater relative to Table 1, revenues received from the logger by the contracted driver are used to pay for all costs associated with hauling by the driver themselves. All scenarios assume 30 tons per load (payload) and a pay rate based on a 40-mile minimum haul distance4. An average travel speed of 45 miles per hour was assumed to account for stops at stop signs and stop lights and slow travel speed on unpaved roads. Approaches 3, 5, and 6 are usually not applicable to owner-operators.

Notes for Tables 1 and 2:

1 2,000 pounds per ton.

2 40 minutes driving time each way (driving to the mill and the return trip) for the 30-mile haul, 80 minutes total driving time.

3 80 minutes driving time each way (driving to the mill and the return trip) for the 60-mile haul, 160 minutes total driving time.

4 Given the minimum haul distance of 40 miles, compensation is not based on 30 miles for the 30-mile hauls, but for this example the minimum 40 miles. In some instances, drivers paid using Approach 4 may receive bonus compensation that is dependent on a minimum haul distance. However, for this example there is no bonus salary or additional compensation.

5 Initially based on a 11-hour workday, five days a week, and for 50 weeks of the year. Given travel times and work limitations, Scenario 1 assumes 4 loads a day, Scenario 2 assumes 3 loads a day, Scenario 3 assumes 3 loads a day, and Scenario 4 assumes 2 loads a day. Thus, daily total trucking times by scenario are 9.33 hours, 10 hours, 11 hours, and 9.33 hours for Scenarios 1, 2, 3, and 4, respectively.

|

Approach |

Payment Rate |

Scenario 1 |

Scenario 2 |

Scenario 3 |

|---|---|---|---|---|

|

A1 |

$84/load |

$30.24/hr |

$30.24/hr |

$30.24/hr |

|

A2 |

$0.07/ton/loaded mile |

$30.24/hr |

$22.18/hr |

$38.30/hr |

|

A3 |

41.2% of $0.17/ton/loaded mile |

$30.24/hr |

$22.18/hr |

$38.30/hr |

|

A4 |

$2.80/ton |

$30.24/hr |

$22.18/hr |

$38.30/hr |

|

A53 |

$50,000/yr |

$24.00/hr |

$24.00/hr |

$24.00/hr |

|

A6 |

$25.00/hr |

$25.00/hr |

$25.00/hr |

$25.00/hr |

|

A7 |

$2.10/loaded mile |

$30.24/hr |

$30.24/hr |

$30.24/hr |

Scenario 1 is 30-ton payload (near legal limit)1, 2; Scenario 2 is 22-ton payload (underweight)1, 2; Scenario 3 is 38-ton payload (overweight)1, 2.

All scenarios assume a 40-mile haul distance, the pay rate is based on a 40-mile minimum haul distance, 30 minutes to load, and 30 minutes to unload. An average travel speed of 45 miles per hour was assumed to account for stops at stop signs and stop lights and slow travel speed on unpaved roads.

|

Approach |

Payment Rate |

Scenario 1 |

Scenario 2 |

Scenario 3 |

|---|---|---|---|---|

|

A1 |

$240/load |

$86.40/hr |

$86.40/hr |

$86.40/hr |

|

A2 |

$0.17/ton/loaded mile |

$73.44/hr |

$53.86/hr |

$93.02/hr |

|

A4 |

$10.00/ton |

$108.00/hr |

$79.20/hr |

$136.80/hr |

|

A7 |

$7.00/loaded mile |

$100.80/hr |

$100.80/hr |

$100.80/hr |

Scenario 1 is 30-ton payload (near legal limit)1, 2; Scenario 2 is 22-ton payload (underweight)1, 2; Scenario 3 is 38-ton payload (overweight)1, 2.

Although the hourly wage is greater relative to Table 3, revenues received from the logger by the contracted driver are used to pay for all costs associated with hauling by the driver themselves. All scenarios assume a 40-mile haul distance, the pay rate is based on a 40-mile minimum haul distance, 30 minutes to load, and 30 minutes to unload. An average travel speed of 45 miles per hour was assumed to account for stops at stop signs and stop lights and slow travel speed on unpaved roads. Approaches 3, 5, and 6 are usually not applicable to owner-operators.

Notes for Tables 3 and 4:

1 2,000 pounds per ton.

2 53 minutes driving time each way (driving to the mill and the return trip) for the 40-mile haul, 106 minutes total driving time.

3 Initially based on an 11-hour workday, five days a week, and for 50 weeks of the year. Given travel times and work limitations, this scenario, regardless of payload weights, assumes 3 loads a day. Thus, daily total trucking time is 8.33 hours.

References

Conrad, J.L, IV. 2018. Costs and challenges of log truck transportation in Georgia, USA. Forests 9: 650.

Conrad, J.L., IV, W.D. Greene, & P. Hiesl. 2018. The evolution of logging businesses in Georgia 1987–2017 and South Carolina 2012–2017. Forest Science 64: 671-681.

Conrad, J.L., IV. 2021. Evaluating profitability of individual timber deliveries in the US South. Forests 12: 437.

Grebner, D.L., L.A. Grace, W. Stuart & D.P. Gilliland. 2005. A practical framework for evaluating hauling costs. International Journal of Forest Engineering 16: 115-128.

McConnell, T.E. 2020. Unit costs and trends within Louisiana’s logging contract rate. Forest Products Journal 70: 50-59.

TimberMart-South. 2022. Biomass, logging rates, & species detail 1st quarter 2022. Norris Foundation, Athens, GA.

Appendix

Ton/loaded mile – this is an extremely important measure and concept related to hauling harvested raw woody resources. As mentioned in Figure 1, a ton/loaded mile is a measure that is based both on the weight of a load and distance traveled. The heavier the load, and the greater the haul distance, the greater the compensation. Additionally, the word loaded is used because any compensation based on a ton/loaded mile concept only applies to when the truck is loaded with logs (see Figure 1). This then leads to the phrase $/ton/loaded mile, indicating some amount of compensation, or revenue, depending upon the ton/loaded mile value.

For illustrative purposes, let us assume there is a mill located in Bowie, Mississippi. Given markets, let us assume they have a 40-mile minimum haul (this can vary by mill, physiographic region, timber value, etc.). Meaning, any haul distance shorter than 40 miles, will be assigned by default a haul distance of 40 miles. The minimum haul distance is used to compensate the log truck owner for the disproportionate amount of time spent loading and unloading on short hauls. On longer hauls, the log truck owner receives the minimum haul rate multiplied by the minimum haul distance, plus an incremental haul rate multiplied by the incremental haul distance (Equation 1). The incremental haul rate may be the same, higher than, or less than the minimum haul rate. Note that the driver will need to slow down while traveling through the towns of Collins and Seminary. This is an example of one reason why an average travel speed of 45 miles per hour was assumed in Tables 1 to 4.

It is nearly 40 miles to Magee, Mississippi (reported to be 40.5 miles). Thus, the blue line along Federal Hwy 49 can be considered the minimum haul distance. Any truck hauling to this conceptual mill using this route whose haul is beyond this point along Hwy 49 will receive the minimum haul distance haul rate for the 40 mile haul, plus the incremental haul rate for the miles in excess of 40 miles.

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

We would like to thank Dr. Scott Barrett of Virginia Tech University and Dr. Patrick Hiesl of Clemson University for providing useful comments.

Publication 3850 (POD-01-23)

By Curtis L. VanderSchaaf, PhD, Assistant Professor, Central Mississippi Research and Extension Center; Joe Conrad, PhD, Assistant Professor of Forest Operations, Warnell School of Forestry & Natural Resources, University of Georgia; Wayne Withers, Instructor, Logger Equipment Operator Academy, Hinds Community College; and David Livingston, Executive Director, Mississippi Loggers Association.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.