Tree Injection for Timber Stand Improvement

Undesirable vegetation can drastically reduce commercial production in forests. Pine stands containing 20–30 percent hardwood basal area can suffer up to a 50 percent reduction in pine volume growth, or be so thick that sunlight does not reach the forest floor at levels sufficient to maintain vegetation needed by wildlife. Conversely, hardwood stands may contain species undesirable for landowner objectives. In either case, if undesirable stems become large enough, they can no longer be easily controlled through prescribed burning or herbicide applications appropriate for low-growing vegetation. Millions of acres of Mississippi’s commercial forestland could benefit from control of these larger undesirable stems (Figure 1).

One of the more appropriate methods for controlling large unwanted stems is individual stem treatment with herbicides. Three commonly encountered modes of individual stem treatment exist (e.g., basal bark, injection, and hack-and-squirt). While “injection” technically describes a treatment method involving more specialized equipment (described below), injection and hack-and-squirt are often referred to collectively as “injection.” Due to susceptibility of most hardwoods to a wide array of forest herbicides, injection may be the only herbicide application capable of controlling these stems without unintended damage to crop trees in hardwood stands. This method can be particularly attractive to private landowners since the technique is easy or can be easily contracted and supervised as they see fit. If needed, it can be performed throughout most of the year, but the greatest levels of efficacy are achieved during fall and winter months. Additionally, if landowners complete the work themselves, it can be performed as time permits with very low investment in equipment. Landowners can treat even large acreages if timing is not a limiting factor.

Tree injection involves depositing herbicide into undesirable tree stems using cuts spaced around the trunk of the tree with an ax, hatchet, machete, or tree injector. Non-overlapping horizontal cuts that penetrate into the sapwood are cut around the tree.

A small quantity of herbicide is then deposited in each cut. The precise amount of herbicide used is specific to the herbicide label, but per-acre rates are typically very small compared to broadcast rates. Tree injection is more effective and less expensive than mechanical girdling with or without herbicide. This is primarily a function of less labor involvement (see MSU Extension Publication 3673 Tree Injection with Reduced Labor Requirements).

Injection is applicable in both pine and hardwood systems. However, in hardwood stands, you must consider possible nontarget impact. This is rarely a problem if you follow application procedures and properly complete the method.

Where Is Injection Used?

Historically, injection was widely used during several stages of forest management. Injection was commonly used in combination with other herbicide applications or with prescribed burning. For example, a common practice after timber harvest was to burn logging slash, thus removing planting obstacles and controlling smaller hardwoods. Larger stems could then be treated. The method was used to control undesirable trees during site preparation, release operations, and timber stand improvement (TSI).

Due to improvements in chemical site preparation in pine silviculture, injection has become relatively uncommon in these systems. However, the technique is widely used in hardwood TSI work and natural regeneration efforts. Injection is typically reserved for use on stems larger than 1 inch diameter at breast height (DBH) and in areas with up to 350–400 undesirable tree stems per acre. While the method is effective on smaller stems and greater numbers of stems per acre, labor cost becomes prohibitive when smaller/more stems are treated.

Benefits

As with any herbicide treatment, perfect—or even good—control is not automatic. Control can range from 20 to 100 percent, depending on a variety of factors. Inadequate control of targeted stems can result from using an herbicide not effective on the species being controlled, applying herbicides without regard for proper timing (for example, injecting imazapyr during the spring when fluids are traveling to the crown), or injecting herbicides while trees are under severe drought stress. However, if all factors are accounted for, you can expect excellent control. For example, in a recent North Mississippi injection study, over 72,000 stems were injected across 90 acres (Alkire et al. 2012). Injected stems included American hornbeam, blackgum, deciduous holly, green ash, several hickory species, paw-paw, red maple, sweetgum, winged elm, and red buckeye. These stems, along with those of several other species occurring in minor quantities, exhibited first-year control of 96.8 percent. These results mirror those observed in many commercial injection efforts.

Tools Needed

Some of the earliest tree injection efforts involved the use of basal injectors, also known as Jim-Gem injectors, Cranco injectors, or Cran-Jectors. These hollow, tube-like tools were first jabbed into the base of a tree targeted for control (Figure 2). Then, depending on which tool was being used, a wire was pulled or a handle was pushed, allowing herbicide to flow into the cut made by the tool. Basal injectors worked but were difficult to use because their weight and tool design resulted in herbicide spills. As other injection tools and methods were developed, basal injector use became virtually nonexistent.

Currently, two primary types of tree injection are used:

- Injections performed using the Hypo-Hatchet tree injector.

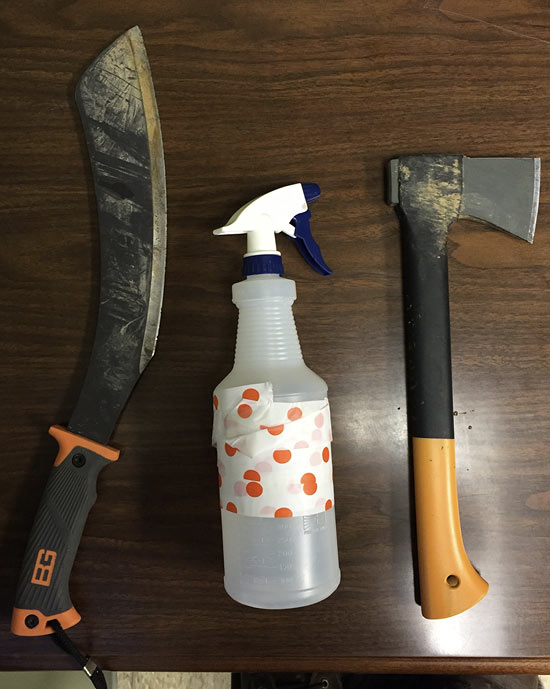

- The “hack-and-squirt” method, where cuts are made with a hatchet or machete and the herbicide is sprayed into the cut using a squirt bottle.

The Hypo-Hatchet tree injector (Figure 3) was developed as a less laborious tool for injection work. The tool consists of a modified hatchet designed to inject a small amount of herbicide when struck into a tree. Herbicide mixtures are carried in a reservoir bottle worn by the applicator. To inject a tree, the applicator strikes the stem using a 45-degree angle with enough force for the blade to cut to sapwood depth. This creates enough force for a set amount of herbicide to be deposited in the cut. The tool is engineered to deliver 1 milliliter per injection and is not equipped for recalibration at other delivery rates. Recommended injection rate is one injection per inch of tree DBH. In addition, suggested cut spacings are set at no more than 1.5 inch. Injections are performed at waist height.

While treatments performed with the Hypo-Hatchet are typically successful, the cost of the tool and its accessories often turn prospective buyers away. Hypo-Hatchets can be purchased from several vendors specializing in forestry supplies and can typically be purchased for $450 to $500.

Hack-and-squirt is relatively inexpensive and only requires a cutting tool (ax, hatchet, machete) and a squirt bottle (Figure 4). A squirt bottle (the inexpensive kind easily found in most garden centers) may or may not be adjustable in the amount of spray output per squeeze. However, calibration tests have shown a consistent 1.0–1.2 milliliter output rate for most spray bottles. Long-term use of these bottles may not be possible due to solvent degradation caused by some herbicide formulations; however, they are inexpensive and easy to replace. If extended season-long use of application bottles is needed, MSU Extension Publication 3276 Applying Herbicides with the Hack-and-Squirt Method provides detailed information regarding using hydration backpacks and line-fill vaccinators in hack-and-squirt applications.

Hack-and-squirt is cheaper to use because the equipment is less expensive, it uses less herbicide than other injection methods, and it requires less labor. With traditional systems, no more than 1 inch between cuts was allowed, and typically cuts overlapped around the stem (girdling, frill cutting). Using current injection techniques, injections can be applied at a rate as low as one “hack” per 3 inches of DBH (Figure 5). While several herbicides are labeled for tree injection, testing has shown the herbicide imazapyr exhibits the greatest overall efficacy and range of species controlled when used in this work. The current standard uses a rate of:

1 cut per 3 inches of stem DBH with a 1 ml deposit of a 20 percent imazapyr solution [4 lb imazapyr product (e.g., Arsenal AC, Imazapyr 4 SL)] with water comprising the remaining 80 percent.

Imazapyr is a slow-acting herbicide; consequently, control of injected stems will increase between years 1 and 2 post-treatment. In some situations, control may appear to be less than acceptable at the end of the first growing season, but trees are usually dead by the end of the second growing season.

While imazapyr will control most tree species of concern, some species (e.g. legume species such as eastern redbud, black locust, etc.) will not be controlled using the aforementioned treatment. In most cases, other herbicides (primarily products containing triclopyr) may be used for control of those species. However, imazapyr injection will control some species which are somewhat resistant to foliar applications (e.g. elm and hickory species). Also, one should consider that as tree diameter increases, injection efficacy decreases and controlling large diameter trees of any species may prove difficult (Figure 6).

A very important, often-overlooked factor in injection efforts is that of making a proper cut. The cut should be cup-shaped so that it holds the herbicide until the tree can take it up (Figure 7). Edges of the cut should not be torn because this allows herbicide leakage. The cut should also be relatively deep so that herbicide can reach the woody part of the tree instead of being held in the bark only (Figure 8).

Maintaining Injection Equipment

Most equipment is durable if well maintained, and injection equipment is no exception. Thoroughly rinse the Hypo-Hatchet after use each day. Flush it with water to remove herbicide residue. Remove the piston, and clean and lubricate it daily. Use silicone grease to lubricate the cylinder and O-rings. In addition, regularly inspect the piston flap valve, O-rings, and chamber gasket to avoid undue wear on the system.

Thoroughly rinse both the herbicide reservoir and the lines to remove residual herbicide. In the event that something breaks, replacement parts can be purchased from appropriate suppliers; you can reduce downtime by having a few spare parts on hand.

If employing hack-and-squirt, rinse hatchets/machetes daily, and keep them clean and dry when not in use. Lightly oil metal tool parts to prevent rusting. Repair or properly dispose of tools with loose or otherwise compromised handles. Spray bottles should receive the same rinsing treatment mentioned above for the Hypo-Hatchet spray reservoir.

Keep all injection tool edges sharp to ensure effective bark penetration and reduce arm fatigue when injecting stems. You can take files to the field to sharpen edges as needed. Always take caution when using any injection equipment because blade edges can cause serious injury or death when used improperly.

Pros and Cons

Each of the two injection systems being discussed has advantages and disadvantages. When selecting equipment, consider tool durability, projected use, maintenance requirements, and cost.

Hypo-Hatchet: Since this equipment is relatively light and used with only one hand, some users report “shock” or vibration in the arm. This problem is exacerbated when injecting species with denser wood. In areas with thick underbrush, the tube between the hatchet and herbicide reservoir may get caught on branches. Daily cleaning is essential to keeping the system functional. Additionally, some parts like herbicide tubing, O-rings, and gaskets wear out relatively quickly, leading to the need for frequent inspection and subsequent maintenance. The system is relatively expensive, but it applies a calibrated amount of herbicide consistently.

Hack-and-squirt: The same vibration problems and arm fatigue associated with the Hypo-Hatchet will be experienced with this method. Unless squirt bottles are calibrated, too much or too little herbicide may be applied. If equipment is damaged or misplaced, replacements are as close as the next hardware or gardening store. The greatest advantages to the system are reduced equipment cost and maintenance.

Timing and Cost

The productivity of an injection crew depends on a number of variables. These include: the number of trees to be injected, the species to be controlled, site accessibility, and injection crew size. Thus, most contractors bid on each job only after careful inspection of the site. On average, you can expect somewhere in the neighborhood of 3–5 acres per man-day. This equates to about 1/2–1 gallon of herbicide solution injected per man-day. Rough terrain or increasing the number of trees treated per acre will decrease an injection crew’s productivity. Conversely, fewer treated trees per acre and easier terrain will increase the treated acreage rate per day.

Injection methods have low investment costs. Equipment ranges from $25 with hack-and-squirt to over $500 when using the Hypo-Hatchet. If you use imazapyr, herbicide costs range between $1 and $8 per acre. Injection does require proper application to be effective and is labor-intensive. As such, contract application costs can range anywhere between $125 and $150 per acre. Expect higher labor costs in stands with greater numbers of stems to be treated.

How Safe Is Tree Injection?

Injection work requires proper and safe handling of herbicides and equipment. Every container of herbicide comes with a product label attached that should be read and followed. This label details a variety of information ranging from suggested application rates to safety instructions. Workers should wear eye protection both when handling herbicides and when actually injecting stems. Always use latex, vinyl, or neoprene gloves when handling herbicides. Keep plenty of washing water on hand, and change and launder clothing daily.

Dispose of rinse water properly per label instructions. Do not wash equipment or dispose of contaminated water near drinking water sources or near plants that are not to be killed. Imazapyr is a soil-active herbicide, and nontarget impact can easily result from careless use or herbicide leakage. Triple-rinse all empty containers before discarding in an approved location.

Many people are concerned with the possibility of harming themselves or others through exposure to herbicides. Imazapyr is a safe compound with very low toxicity. When comparing the toxicity of any substance, a commonly used measure is that of lethal dose 50 (LD50). An LD50 rating is simply the concentration of a compound (measured in milligrams of said compound per kilogram of body weight) needed to kill 50 percent of the test population (typically mice, rats, or rabbits). Higher LD50 ratings indicate lower toxicity, and lower LD50 ratings indicate substances of greater danger. Imazapyr has a greater LD50 (so is less toxic) than many common substances used in everyday life, including table salt, baking soda, aspirin, caffeine, gasoline, and vitamin D. For more information regarding herbicide toxicity and safe use of imazapyr and other forest herbicides, please read MSU Extension Publication 1874 Forest Herbicide Safety: Environmental Concerns and Proper Handling.

Summary

Tree injection is a very effective method for controlling undesirable trees. The method is best applied to stems of 1 inch or greater DBH and in stands with injected stem densities of 400 trees per acre or less. Imazapyr injection under these parameters can be very effective as well as biologically and economically beneficial in your forest management efforts.

Additional Reading

Alkire, D. A., Ezell, A. W., Self, A. B., Demarais, S., Strickland, B.K. 2012. Efficacy and non-target impact of midstory injection in bottomland hardwoods. In: Proceedings of the 16th Biennial Southern Silviculture Research Conference, e-Gen. Tech. Rep. SRS-156. Asheville, NC: USDA Forest Service, pp 3-6.

Byrd, J. D. 2018. Applying Herbicides with the Hack-and-Squirt Method. Mississippi State University Extension Publication 3276. 2p. Self, A. Brady. 2015. Tree Injection with Reduced Labor Requirements. Mississippi State University Extension Service Publication 3673, 2p.

Self, A. B. and A. W. Ezell. 2020. Herbicide Options for Hardwood Management. Mississippi State University Extension Publication 2873, 8p.

Self, A. B. 2020. Forest Herbicide Safety: Environmental Concerns and Proper Handling. Mississippi State University Extension Publication 1874, 4p.

Self, A. B. 2019. Timber Stand Improvement. Mississippi State University Extension Publication 1281, 4p.

Self. A. B. 2021. Tree Injection with Reduced Labor Requirements. Mississippi State University Publication 3673, 2p.

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

Publication 2942 (POD-05-22)

By A. Brady Self, PhD, Associate Extension Professor, Forestry.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.