Soil Steaming 101

Purpose of Soil Steaming

Crops face many challenges throughout the season, many of which stem directly from the soil, including weeds, soilborne diseases, and insects. These pests hinder plant growth, leading to reduced yields and even crop devastation. Nutrient-dense soils, free of insect pests and disease pathogens, are fundamental to maximizing yields and maintaining crop quality across various production systems. Managing weeds, soilborne pathogens, and insect pests is a top priority for producers.

Farmers must monitor these issues and address them regularly throughout the crop cycle to prevent them from impacting crop yields. For example, weed seeds continually germinate throughout the season, making weeding a weekly chore throughout the crop cycle. A farmer may use hoeing or tine weeding each week to target germinating seeds. They may also shade the soil surface with organic and inorganic mulches to prevent weed growth. Managing weeds in this manner can reduce the number of viable seeds in the soil seed bank over time, but other methods can be used to disinfest (i.e., reduce or remove) weeds and pathogens from the soil.

Numerous methods have been developed to disinfest soils, such as fumigation and soil solarization. The focus of this publication is soil steaming, where soils are warmed to temperatures that disinfest pathogens, insects, and weeds from soils. This environmentally friendly fumigant alternative can generate higher yields with less labor throughout the growing season.

Historical Context

Soil steaming originated in the 1800s but fell out of favor as pesticides, such as soil fumigants and herbicides, became more commonly used. Methyl bromide is a particularly effective soil fumigant used worldwide, but concerns over high toxicity and its damage to the ozone layer led the Environmental Protection Agency to phase it out of use in 2005. Demand for organic production and bans on methyl bromide have led to a search for alternative methods of soil disinfestation; therefore, interest in soil steaming has grown in recent years.

Steaming Overview

Soil steaming is a non-selective (i.e., broad-spectrum) heat treatment that suppresses weeds, pathogens, and insect pests. It can also be used in organic crop production for weed control as it provides a “clean slate” for planting without the input of chemicals. Unlike practices involving pesticides, soil steaming does not leave residues, nor does it have a field re-entry time. Producers can plant in the soil as soon as it has cooled, usually the next day.

With soil steaming, weed and soilborne pathogen control typically lasts several months, significantly reducing manual labor and pesticide input throughout the season. Soil steaming also releases macro- and micronutrients that increase plant growth. Plants grown in steamed soils are often larger and healthier than those grown in unsteamed soils, even when compared to plants grown in plots that are kept weed-free.

Steam is produced in a generator or boiler and applied to the soil in various methods. For example, injection steaming involves infusing steam into the soil through perforated pipes or steam-injection lances. The pipes or lances are inserted into the soil at regular intervals, and steam is released directly into the soil profile. This method allows for deeper steam penetration and is more effective at disinfesting the soil at greater depths, such as 8 to 12 inches. Injection steaming requires specialized equipment and is typically used in large-scale agricultural operations.

Subsurface steaming uses pipes or hoses buried below the soil surface. The steam makes its way through small perforations in the pipes. It then rises through the soil profile, disinfesting the soil as it moves upward. This method can effectively control soilborne pathogens and pests that reside deeper in the soil. Subsurface steaming is usually much less portable than other methods; therefore, it is commonly used in greenhouse production systems.

Mobile steaming uses a self-propelled steam generator that moves over the soil surface, delivering steam as it goes. It is designed to treat large areas quickly. Mobile steaming is often used in open-field crop production, where large-scale soil disinfestation is required.

Surface steaming, which is the primary focus of this publication, applies steam directly to the soil surface, usually through a network of pipes or hoses with holes that allow the steam to escape. It’s designed to heat the top 2 to 6 inches of soil. Because the pipes or hoses are laid out on the soil surface, the rising steam is captured by a trap fixed to the soil surface (using something like chains around the perimeter), preventing the steam from escaping. This method is generally suitable for small-scale applications (high tunnels, greenhouses, or smaller farms such as those under 5 acres) and can be performed using portable steamers.

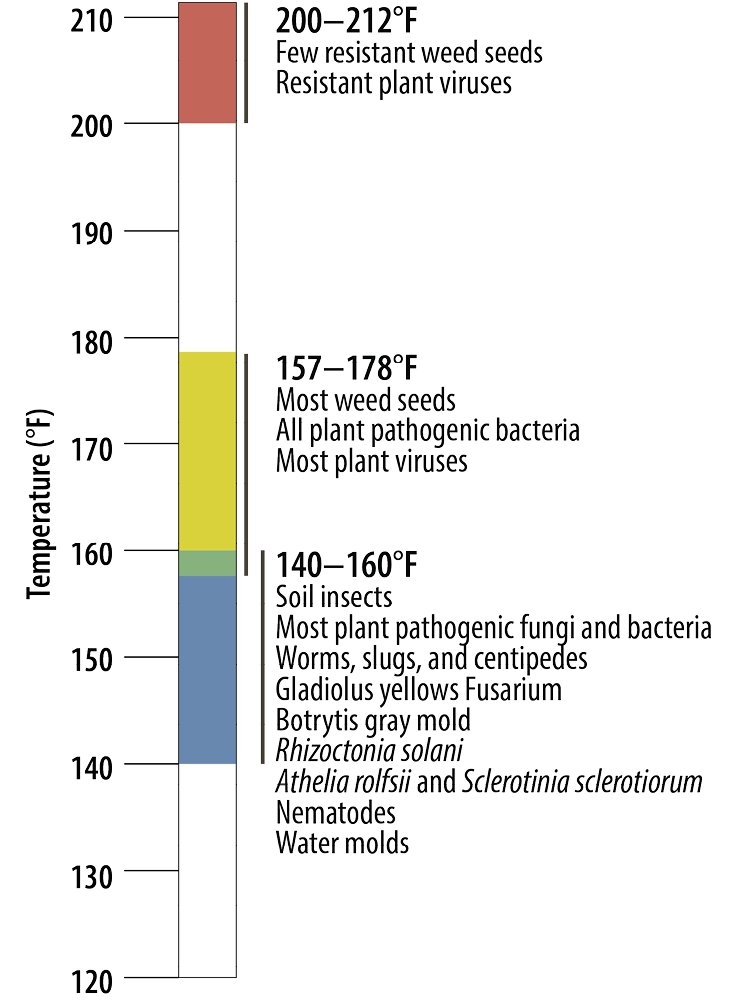

Regardless of the delivery method, soil temperature is monitored during steaming. Target temperatures are typically between 160 and 180°F, successfully controlling most plant pathogenic fungi and bacteria, slugs, nematodes, plant viruses, and weed seeds (Figure 1). Some research recommends holding it at the desired target temperature for 30 minutes, while other studies report no difference in weed or tomato southern blight control in soils held at 160°F for just 5 minutes at a depth of 4 inches. Exceeding 180°F can harm the soil structure (making it less porous) and alter its chemistry; therefore, it is not recommended. Steaming for less time and lower target temperatures conserves fuel and allows a larger area to be steamed in a shorter time. Both time and temperature should be carefully adjusted based on the targeted pest to optimize fuel and time use.

Considerations for Soil Steaming

There are important considerations for soil steaming disinfestation. It may take a long time to provide uniform steam coverage over a large area. The time it takes to reach target temperatures can vary and is hindered by excessive soil moisture. Therefore, rain may result in delayed planting dates. Additionally, the area of a field that can be treated at one time is limited to the capacity of the steam generator.

Another disadvantage is that, like other broad-spectrum treatments such as fumigation, soil steaming reduces all soil microbes, even beneficial ones. This may reduce crop yield, such as in legumes that benefit from beneficial nitrogen-fixing microbes (like rhizobia) or in other crops that benefit from microbes that mobilize phosphorus to the plants (like mycorrhizae). Many beneficial microbes can be manually reintroduced by planting inoculated plants or seeds. Or they can be applied to the soil directly and incorporated into the top inch or two.

Farmers often inoculate crops with beneficial microbes, even on farms with soils that are not disinfested. Many commercial potting soils have beneficial microbes, especially mycorrhizae, already added to them; therefore, transplants grown in these media may not need to be inoculated unless specific needed microbes are not included. Microbial populations are also reintroduced naturally over time through dust particles that land on the field and as water, insects, animals, and worms move through the field.

In contrast to conventional pesticides, soil steaming equipment is less readily available, and the initial equipment costs can be high. Using fossil fuel energy to operate the equipment and generate steam is a concern for some producers. The total cost of steaming depends on the size of the steamer, the starting soil temperature, wind and ambient temperatures, the ability of the steam to penetrate the soil, and the field size. These factors determine the time and fuel required for application.

Labor costs must also be considered. Surface steaming requires workers to prepare the site for steam application by preparing rows, laying and securing the heat-resistant plastic tarps, and operating the equipment. With an organized plan and enough workers, a surface steaming system requires 3 hours to prepare the site (tilling, laying rows, etc.), plus time (usually around an hour) to operate the steamer.

Equipment and Parts for Surface Steaming

When surface steaming soils, the goal is to raise the substrate (soil) temperature to between 140 and 180°F (usually 160 to 180°F) for the allotted time to kill the targeted pest using low-pressure steam. There are a few manufacturers of steam generators. A common brand is the Sioux Steam-Flo. Sioux’s SF-30 model can produce steam at a rate of 308.4 kilograms per hour (Figure 2). Water can be supplied through an irrigation hose or a tank. After the initial start-up, the steamer continuously produces steam.

Steam generators are typically placed on trailers so they can be moved to the site. The steam is generated in the boiler and released from the top through an adjustable valve into a reinforced rubber pipe. The stem transitions into a woven nylon sock, where it is released (Figure 3). A reinforced, heat-resistant tarp is secured over the sock, trapping the steam so it can heat the soil. Temperature probes are placed into the soil, typically 2 to 6 inches deep, to monitor the soil temperature during steaming.

Equipment Maintenance and Upkeep

Store steam generators under a shed or structure to prevent rust or corrosion and keep them out of the weather. In regions where freezing temperatures occur, the steamer must be winterized according to the manufacturer’s instructions to prevent damage from water expansion in the plumbing lines.

Equipment Handling and Safety Precautions

Read and follow equipment directions to ensure your safety and eliminate risks. Several safety mechanisms, such as the pressure-relief valve and the low-water sensor, are built into steam generators (Figure 4). This prevents pressure from building to dangerous levels within the steam generator. If proper maintenance is performed, the steam generator will be safe.

Parts of the steam generator can become hot during operation, so avoid touching these parts (Figure 5). Contact with steam can also cause severe burns and bodily harm. Use personal protective equipment, such as heat-resistant gloves, when handling hot objects. Wear pants and closed-toe shoes. A face shield provides additional protection from steam.

Application Techniques and Protocols

Once the site is prepared for steaming, install a temperature probe to monitor steaming. Then, set a permeable nylon sock on the bed, followed by a tarp to cover the bed and sock. The tarp must be secured around the perimeter using chains, wood boards, soil, or other heavy objects to prevent steam escaping and heat loss. Make sure the tarp does not have holes that will allow steam to escape. See Figure 6.

Once everything is in place, attach the hose hooked to the nylon sock to the boiler. The steam boiler must be filled with water from a tank or another water source. After the boiler is leveled and filled, it is ready for operation. Water is heated in a fuel-powered boiler where the steam builds up pressure. At around 10 PSI, open the valve connected to the hose to release steam into the nylon sock. (At 10 PSI, the steam temperature reaches 240°F.)

Monitor the soil temperature during the steaming process. Once the soil reaches the desired temperature, adjust the steam flow valve to prevent the soil from overheating but allow enough steam to maintain the target temperature for the intended time. After it is finished steaming, turn the boiler off. When removing the chains from the tarp, be very careful so that the steam does not harm any workers.

Following the application process, take care to avoid contamination via tools, clothing, and shoes. Also, soil at deeper levels will not be disinfested; therefore, it is important not to disturb the soil in a way that would bring weed seeds and pathogens from deeper levels up to the soil surface.

Environmental Conditions

Soil moisture conditions must be considered when planning steam treatment. Make sure the soil isn’t excessively wet at the time of steaming, either from rain or irrigation. If the soil, when squeezed in your fist, maintains its shape when pressed and is sticky to the touch, it is too wet for efficient steaming. Increased soil moisture increases the time needed for soils to reach target temperatures. This translates into increased labor and fuel expenses.

Bed Prep

The rows/beds must be prepared appropriately for adequate steam penetration. Tilling increases soil porosity and promotes steam movement through the soil profile. Bed preparation before steaming ensures that there will not be any contamination after the steaming process. Cultivation after treatment will bring new weed seeds, insect pests, and other contaminants to the surface.

Target Organisms

When considering steam as a disinfestation method, it is important to consider the current challenges in the steamed field. Steam is effective against soilborne pests. These pests commonly include nematodes, insects, bacteria, fungi, slugs, and weeds. Steam is effective in treating nematodes, but it may not prevent them. Nematodes are mobile pests that can rise through the soil profile and reinfect steam-treated soils.

Diseases caused by bacterial, fungal, and viral pathogens are prime candidates for steam treatment. With a target temperature of approximately 160°F, most pathogens are destroyed or inactivated because heat treatment affects the integrity of proteins and other structures crucial to these pathogens’ survival.

Weeds are susceptible to steam treatment. Germinated weeds are easily eradicated with exposure to steam. Most weed seeds are also inactivated, and germination rates are reduced.

Some weeds may have propagules in soil profiles below the reach of steam treatments. For example, established nutsedge populations develop 6- to 8-inch-deep tubers, which often escape the killing temperatures reached in shallower soils. Steaming raises the temperature of deeper soils, even down to 12 inches, and these warmer temperatures promote nutsedge tuber growth, causing an increase in nutsedge populations after soil steaming. Additionally, the steam removes other weeds that would compete with the nutsedge, allowing it to grow prolifically. More research on steam delivery is being conducted to identify methods to control existing nutsedge.

Economics

The economic practicality of surface soil steaming varies based on the crop value and the target pathogens, insects, or weeds. While soil steaming has the potential to increase yields greatly, it is not always economical for all situations. For example, high-value crops, such as cut flowers or specialty crops typically grown on a smaller scale, would be more economically viable than crops such as wheat. Additionally, it can be used in high-tunnel and greenhouse production for disinfesting pots, media, and in-ground greenhouse production.

Soil steaming would also be more economical in organic production settings where higher values are often obtained. The economic feasibility would depend on the increase in yield, the cost of the equipment, and fuel costs. It is important to consider the long-term benefits and effects of steaming, including preventing new outbreaks, stabilizing yields, reducing labor throughout the growing season, and reducing hazards of using herbicides and their effect on the surrounding environment. The principles of organic production revolve around economic, environmental, and food safety concerns, as the goal is to make the growing process more sustainable. Steaming may be a useful method in situations where it can be useful and profitable for farmers.

References

Abouziena, H. F., & Haggag, W. M. (2016). Weed control in clean agriculture: A review. Planta Daninha, 34(2), 377–392.

Acton, D. F., & Gregorich, L. J. (Eds.). (1995). The health of our soils: Towards sustainable agriculture in Canada. Centre for Land and Biological Resources Research, Research Branch, Agriculture and Agri-Food Canada.

Arancibia, R. (2020). Soil steaming to reduce the incidence of soil-borne diseases, weeds, and insect pests. Integrated Pest Management: University of Missouri.

Baker, K. F. (Ed.). (1957). The U.C. system for producing healthy container-grown plants. California Agriculture Experiment Station and Extension Service Manual 23.

Bijl, R. (2021). How to sterilize soil with steam. Royal Brinkman.

Biswas, S., Ali, M. N., Goswami, R., & Chakraborty, S. (2014). Soil health sustainability and organic farming: A review. Journal of Food Agriculture & Environment, 12(3 & 4), 237–243.

Fennimore, S. A., & Goodhue, R. E. (2016). Soil disinfestation with steam: A review of economics, engineering, and soil pest control in California strawberry. International Journal of Fruit Science, 16(sup1), 71–83.

Fernandez-Cornejo, J., Osteen, C., Nehring, R., & Wechsler, S. (2014). Pesticide use peaked in 1981, then trended downward, driven by technological innovations and other factors. U.S. Department of Agriculture Economic Research Service.

Gamliel, A., & van Bruggen, A. H. C. (2016). Maintaining soil health for crop production in organic greenhouses. Scientia Horticulturae, 208, 120–130.

Gay, P., Piccarolo, P., Ricauda Aimonino, D., & Tortia, C. (2010). A high efficacy steam soil disinfestation system, part II: Design and testing. Biosystems Engineering, 107(3), 194–201.

Gelsomino, A., Petrovičová, B., Zaffina, F., & Peruzzi, A. (2010). Chemical and microbial properties in a greenhouse loamy soil after steam disinfestation alone or combined with CaO addition. Soil Biology and Biochemistry, 42(7), 1091–1100.

Lehmann, J., Bossio, D. A., Kögel-Knabner, I., & Rillig, M. C. (2020). The concept and future prospects of soil health. Nature Reviews Earth & Environment, 1(10), 544–553.

Melander, B., & Kristensen, J. K. (2011). Soil steaming effects on weed seedling emergence under the influence of soil type, soil moisture, soil structure, and heat duration. Annals of Applied Biology, 158(2), 194–203.

Rosskopf, E. N., Chellemi, D. O., Kokalis-Burelle, N., & Church, G. T. (2005). Alternatives to methyl bromide: A Florida perspective. Plant Health Progress, 6(1), 19.

Roux-Michollet, D., Czarnes, S., Adam, B., Berry, D., Commeaux, C., Guillaumaud, N., Le Roux, X., & Clays-Josserand, A. (2008). Effects of steam disinfestation on community structure, abundance, and activity of heterotrophic, denitrifying, and nitrifying bacteria in an organic farming soil. Soil Biology and Biochemistry, 40(7), 1836–1845.

Sioux Steam-Flo Steam Generators for Greenhouse and Nurseries. (n.d.). Greenhouse and nursery applications.

Thomas, W. B. (1996). Methyl bromide: Effective pest management tool and environmental threat. Journal of Nematology, 28(4S), 586–589.

Weil, R. R., & Brady, N. C. (2019). Elements of the nature and properties of soils (4th ed.). Pearson Education, Inc.

Ye, X. (2021). Penstemon’s centromeric histone 3 variation and the impact of soil steaming on high tunnel tomato production (Doctoral dissertation). Mississippi State University.

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

Publication 4033 (POD-08-24)

By Shaun R. Broderick, PhD, Associate Extension/Research Professor, Truck Crops Branch Experiment Station; Te-Ming Tseng, PhD, Associate Professor, Plant and Soil Sciences; Christine Coker, PhD, Extension/Research Professor, Coastal Research and Extension Center; MacKenzie Cade, Research Associate, Truck Crops Branch Experiment Station; Brenton Breland, Extension Agent I, Pike County; and Erika Sweeten, Research Technician, Truck Crops Branch Experiment Station.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.