Interpreting Forage and Feed Analysis Reports

Forage and feed quality analysis is often referred to as forage and feed testing. It involves determining nutrient levels in forages and feeds, and it is one of the most effective feed and forage management tools. Lab analysis eliminates guesswork when matching forage and feed supplies to animal nutrient requirements, designing supplemental feeding programs, and evaluating forage production.

Many forage producers advertise forages as “leafy,” “green,” or “high quality,” based on visual appraisal, but this can be inaccurate. Visual appraisal often does not reflect forage nutrient content. Feeds are sometimes sold without detailed nutrient composition values and/or with vague ingredient listings. Laboratory analysis is the recommended way to determine forage and feed nutrient content.

Submit feed and forage samples to a certified laboratory for analysis. Knowing the nutritional value of the feed can drive management decisions, including whether or not to supplement feed. Not knowing the nutritive value of a feedstuff can lead to less than optimum resource management such as not supplementing feed enough or wasting money on unneeded supplements. Knowing how to interpret and use feed and forage analysis results is important for livestock producers.

Components of a Nutrient Analysis Report

It is important to understand forage quality terminology to interpret forage nutrient analysis reports effectively. Below are definitions of and typical ranges for the various common components of a nutrient analysis report.

Moisture

Moisture is water in a feed or forage. Moisture level is particularly important in stored forage samples. Excessive moisture levels in hay crops can lead to hay heating, quality losses, and even hay fires. Hay samples with moisture above 18 percent in round bale form and more than 20 percent in small square bale form have significant risk of heating that can lead to fire or nutrient losses.

Silage or baleage should fall within the recommended range for moisture content at harvest (depends on the crop ensiled and type of silo used) to ensure proper ensiling conditions. Silage can be made over a wide range of moisture contents. However, low moisture may lead to overheating, lowered feeding value, and increased dry matter losses.

Excessive moisture can result in too much seepage, nutrient losses, and unpalatable silage. High-moisture feeds often have shorter storage lives or require controlled storage conditions to minimize spoilage and mold growth. Moisture content of feeds also impacts palatability by animals. Moisture also plays a role in determining the true value of a feedstuff. For example, if a producer buys a ton of feed with 70 percent moisture, in reality, he or she bought only 600 pounds of usable feed and 1,400 pounds of water and paid to haul the water.

Dry Matter

Dry matter (DM) is the air-dried component of the feedstuff with all the moisture removed. To calculate DM content, simply subtract the moisture content from 100. Forage and feed nutrient composition can be evaluated on a DM or as-fed (as received) basis. The as-fed basis includes moisture content in each nutrient listing. For a given sample, as-fed nutrient values are always smaller than DM nutrient values.

Most nutritionists prefer to view nutrient content of a feed or forage from the DM basis for two reasons. First, the animal uses the nutrients on a DM basis. Second, it makes ration building easier because it lets all feeds be compared on the same basis. Therefore, producers should focus on interpreting the DM basis calculations on forage and feed analysis reports instead of the as-fed calculations.

Most “dry” feeds, such as grains and hays, often have a DM content of around 85–92 percent. “Wet” feeds, such as silage and wet distiller’s grains, typically have a DM content of 25–35 percent. Intermediate feeds, such as baleage, are generally around 50–70 percent DM. All of the nutrients are discussed on a DM basis throughout the remainder of this publication.

Crude Protein

Crude protein (CP) is based on the nitrogen content of the feed. It is 6.25 times the nitrogen content. Any nitrogen will be considered in the total calculation of the protein. This includes nonprotein nitrogen sources, such as urea. Grains generally have a CP content of 8 to 14 percent, with corn often having 7–9 percent and wheat and oats having 12–14 percent. High protein feeds, such as cottonseed meal and soybean meal, often have 40–50 percent CP. Dried distillers grains (DDG) commonly used in this region usually have 23–29 percent but can be highly variable in CP content, depending on the source. Hays commonly have 4–20 percent CP, depending primarily on maturity at harvest as well as fertilization levels, environmental conditions, forage species, and forage cultivar.

Neutral Detergent Fiber

Neutral detergent fiber (NDF). This value consists of all the cell wall contents plus the acid detergent fiber (ADF) contents. It includes cellulose, hemicelluloses, and lignin. Neutral detergent fiber represents the total fiber component of the feedstuff. Typically, this helps predict intake by animals consuming the feedstuff. As NDF increases, intake will likely decline. Unlike ADF, it has no bearing on quality and digestibility. It is generally a value that expresses total fiber content. Values typically range from 50 to 80 percent in most forages. Legumes tend to have lower NDF and ADF values than grasses, and increasing forage maturity raises NDF and ADF values. This assay is generally not conducted on mixed feeds or grains, unless the roughage component of the feed is high.

Acid Detergent Fiber

Acid detergent fiber is the value that corresponds to the level of cellulose and lignin in the plant. It is important because lignin is considered indigestible by the animal. Therefore, ADF is the estimation of the component of the feedstuff that is indigestible. The greater the ADF value, the more indigestible the feedstuff. Typically, grains and mixed rations have a lower ADF, and forages have a higher ADF (around 40 percent).

Total Digestible Nutrients

Total digestible nutrients (TDN) is an estimate of the energy content of the feed or roughage. It is calculated by a formula that uses the ADF, NDF, CP, and ash components of the feedstuff to give an estimated value of energy. Typically, the greater the value, the more energy-dense the feedstuff is considered. Typically, lower quality hays have 40–50 percent TDN, while higher quality hays have 50–60 percent TDN. In some cases, certain hays and legumes may even have 60–70 percent TDN. Grains and grain mixes usually have 70–80 percent TDN. Because NDF is required for TDN calculation in some laboratories, a mixed feed or grain will not have a TDN value, if NDF was not assayed. Therefore, in those cases TDN can be estimated using the ADF value. The formula is 87.84 minus (ADF% × 0.7). This lets producers estimate TDN if NDF is not given.

Net Energy

Most beef cattle producers evaluate the energy content of forages and feedstuffs based on TDN. Although TDN can be used as a guide with regards to energy, other systems have been developed that allow more precise calculations of specific rates of gain and specific milk quantities produced. The net energy system is one such system. This system accounts for energy losses from digestion of different feeds, for which the TDN system does not account. The net energy system allows for partitioning of nutrients based on stage of production. It allows for energy to go toward maintenance or production (lactation or gain). This system is more commonly used when a specific rate of gain is targeted or a specific level of milk production is required.

The Mississippi State Chemical Lab report for feed analysis includes the values of net energy for maintenance (NEm), net energy for gain (NEg), and net energy for lactation (NEl), as well as TDN values. Net energy for maintenance is the energy needed for maintenance functions such as maintaining body temperature, physical activity, heartbeat, and breathing. Net energy for gain is energy used for productive purposes, including deposition of protein and fat. Net energy for lactation is the energy needed for milk production.

Minerals

Mineral values are typically not assayed in general analyses by laboratories. Mineral analyses must often be specifically requested and may entail additional fees. It is recommended that mineral values be assayed at least twice a year to determine if any imbalances are occurring. Most can be corrected simply by feeding an all-purpose beef cattle mineral. If coproducts such as DDG are used, it is recommended that mineral assays be performed. Feedstuffs such as DDG are usually high in certain minerals (phosphorus and sulfur in the case of DDG), which could cause some serious imbalances.

Mineral levels are a bit more confusing to interpret because certain minerals interact with others. Therefore, it is difficult to establish guidelines unless the complete feeding program is known. In these instances, it is best to establish a complete understanding of the total feeding program before diagnosing mineral imbalances or problems. Note that mineral levels in forages are highly variable, so a forage mineral analysis may not be a good indication of the overall mineral situation.

Assessing Overall Forage and Feed Quality

Forage quality is often defined in terms of leafiness, stem thickness, color, smell, or content of protein, fiber, or lignin. Similarly, feed quality is often described in terms of color, odor, texture, and presence or absence of molds. Forage and feed chemical composition is useful in assessing forage and feed quality, but it is the response of the animal that ultimately determines forage and feed quality.

Palatability refers to how acceptable a forage or feed is to an animal. Palatability and intake can become an issue, particularly with lower quality forages. Make sure cattle receiving lower quality forages and feeds have acceptable levels of intake. Animals may spend time seeking out certain forage species and avoiding others, thus affecting bite size and effective forage availability. Cattle generally prefer grasses and legumes over browse. Tannins in forages such as arrowleaf clover can reduce palatability. Nitrogen fertilization generally increases forage protein content and can increase forage palatability. Cattle may even refuse unpalatable feeds, and palatability problems can increase feeding waste.

Forage or feed quality can be evaluated by forage or feed digestibility and nutrient content. More digestible forages and feeds pass through the rumen faster and allow for more forage and feed intake by reducing gut fill. Higher forage or feed digestibility and nutrient content allow the animal to use more nutrients from forage and feed. In forage production, aim for high total nutrient yields (quantity and quality) instead of just high forage yields (quantity). When purchasing stored forages or feeds, value each feedstuff in terms of nutrient contribution to the diet per unit price for each nutrient needed. Consider storage, handling, and feeding advantages and disadvantages of each forage and feed.

Not all forage or feed components are beneficial when consumed by livestock. Anti-quality factors in forages include alkaloids, nitrates, and prussic acid. These compounds can reduce animal performance and negatively impact animal health. MSU Extension Publication 2521 Anti-quality Factors in Beef Cattle Diets addresses this topic in detail.

Animal performance is the essential measure of forage or feed quality. Forage or feed quality is best defined in terms of animal performance such as average daily gain, reproductive rate, or milk production. Ultimately, forage or feed quality must provide adequate intake without compromising animal health and while producing economically acceptable animal performance.

Relative feed value (RFV) and relative forage quality (RFQ) are forage quality terms that account for animal responses to forage quality. Relative feed value accounts for an animal’s expected forage intake and its energy value. It is an index value that ranks forages on ADF and NDF as compared to full bloom alfalfa, which is assigned a RFV of 100. Relative feed value includes digestible dry matter (DDM) and dry matter intake (DMI) in its calculation.

RFV = DDM × DMI ÷ 100

Digestible dry matter (DDM) is the percentage of a forage sample that is digestible. It is an estimate based on the results from animal feeding trials and forage ADF concentrations. Generally, as ADF increases, DDM decreases. Daily dry matter intake of forage and feed is the amount of forage and feed (excluding the moisture content) consumed in a day. It can be an estimate or prediction based on results from animal feeding trials, producer measurements/experience, or measured NDF concentration of a forage.

Relative forage quality is similar to RFV but uses TDN in place of DDM in calculations. Because RFQ calculations include digestible fiber, this index is expected to be more representative of animal performance on the forages tested. Relative forage quality is appropriate for use with all forages except corn silage. Higher RFV and RFQ values indicate higher forage quality.

RFQ = TDN × DMI ÷ 100

Forage Quality Standards

Knowing forage quality in terms of nutrient contribution to beef cattle diets is critical to planning an accurate and efficient nutritional program. Feeding poor quality forages below 8 percent CP or below 52 percent TDN on a dry matter basis limits forage intake and results in poor animal performance. Low-quality forage should not be offered to livestock with high nutrient demands, such as lactating cows or growing cattle. Supplemental feeding programs differ as forage nutrient composition varies and depend upon the class of livestock. Match supplementation programs to forage quality and animal requirements for best animal performance results.

Prime quality is the best quality forage, while quality standard 5 represents the lowest (poor) quality forage. Forage quality improves with higher CP and DDM levels. Forage quality decreases with higher fiber levels. Higher dry matter intakes are often expected on higher quality forages.

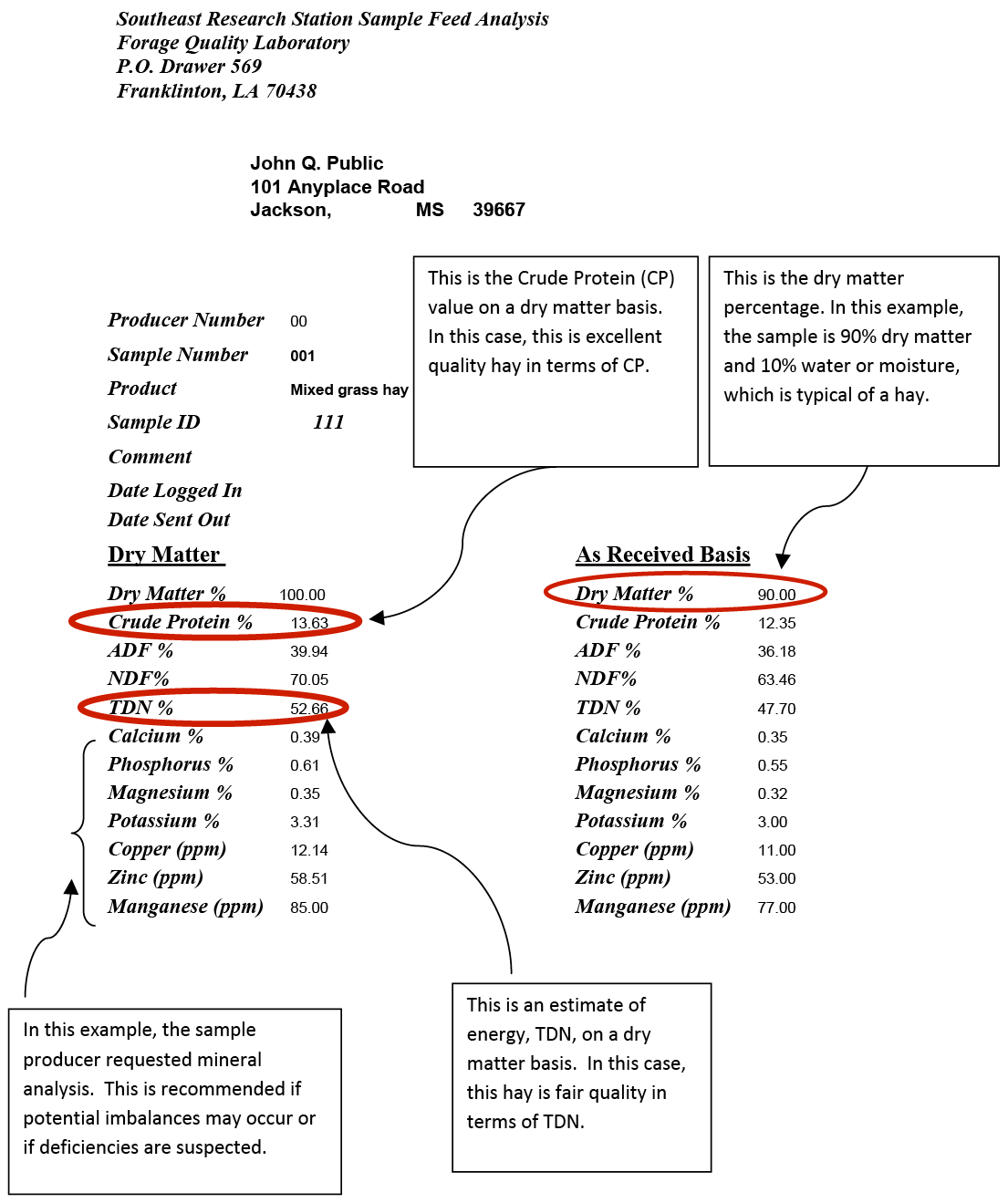

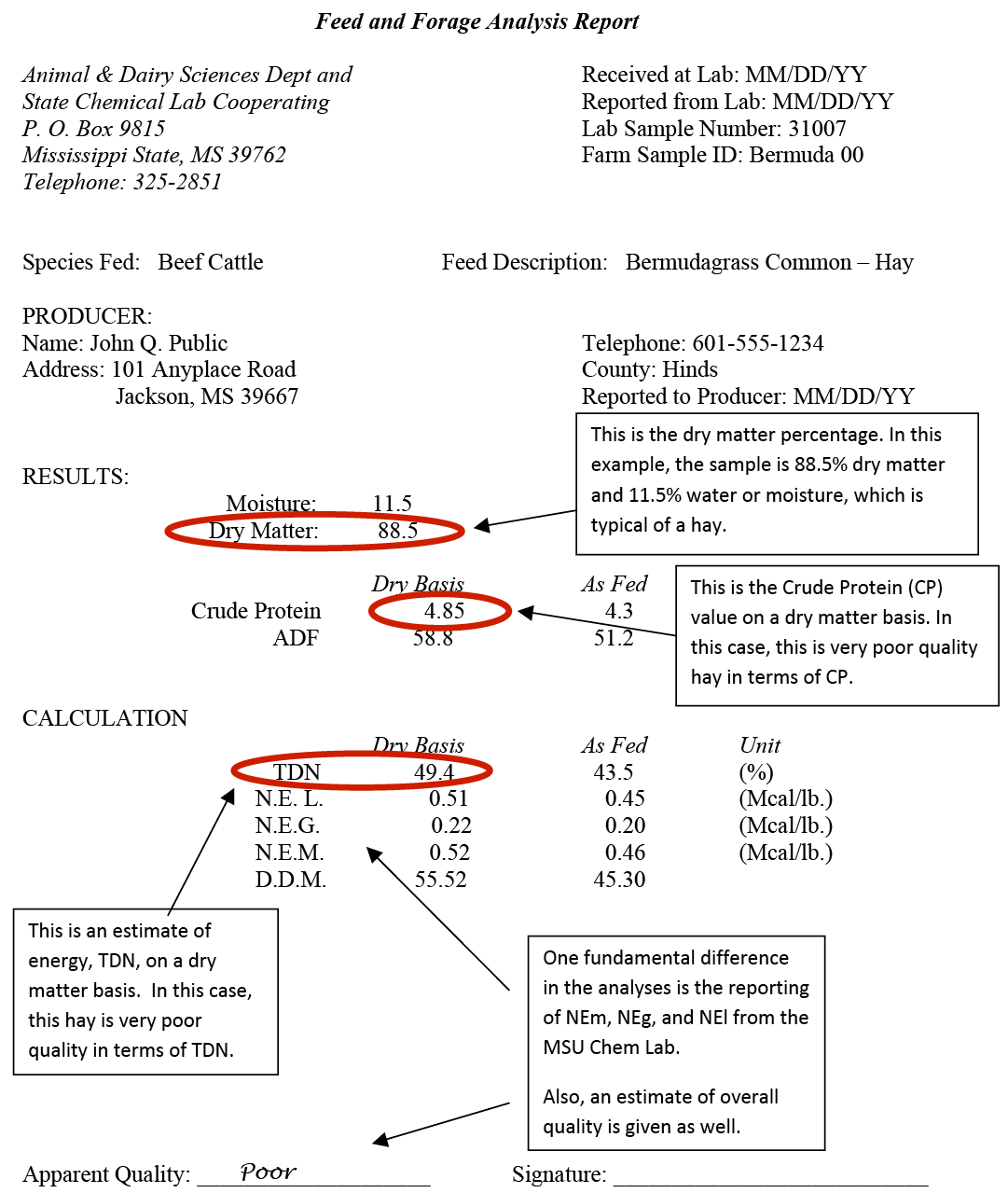

Each hay lot must be uniquely identified to be able to match the harvest date, field of origin, and forage species with the forage quality analysis results. Similarly, each feed sample must be clearly identified, ingredients noted, and matched to a specific feed lot. Sample feed and forage analysis reports from the Louisiana State University AgCenter Forage Quality Laboratory and the Mississippi State Chemical Lab appear on the next pages.

|

Forage Type |

Quality Standard |

Total Digestible Nutrients (TDN)¹ |

Crude Protein (CP)¹ |

Moisture |

pH |

|

silage² |

excellent |

65% or above |

8% or above |

70% or below |

4.2 or below |

|

good |

60–64% |

7–8% |

71–74% |

4.3–4.7 |

|

|

fair |

55–59% |

6–7% |

75% and above |

4.8–5.1 |

|

|

poor |

below 55% |

below 6% |

75% and above |

5.2 or above |

|

|

grass hay³ |

excellent |

58% or above |

12% or above |

||

|

good |

55–57% |

10–11% |

|||

|

fair |

52–54% |

8–9% |

|||

|

poor |

below 52% |

below 8% |

|||

|

legume hay³ |

excellent |

64% or above |

18% or above |

||

|

good |

60–63% |

16–17% |

|||

|

fair |

57–59% |

14–15% |

|||

|

poor |

below 57% |

below 14% |

1Dry matter basis.

2Determine silage quality by total digestible nutrients rating. If silage does not meet either crude protein or moisture requirement for quality, lower one standard.

3Determine hay quality by total digestible nutrients rating. If hay does not meet crude protein requirement or is less than 83 percent dry matter, lower one standard.

|

Quality Standard |

Crude Protein (CP) |

Acid Detergent Fiber (ADF) |

Neutral Detergent Fiber (NDF) |

Digestible Dry Matter (DDM)¹ |

Dry Matter Intake (DMI)² |

Relative Feed Value (RFV)³ |

|

Prime |

above 19% |

below 31% |

below 40% |

above 65% |

above 3.0% |

above 151 |

|

1 |

17–19% |

31–35% |

40–46% |

62–65% |

2.6–3.0% |

125–151 |

|

2 |

14–16% |

36–40% |

47–53% |

58–61% |

2.3–2.5% |

103–124 |

|

3 |

11–13% |

41–42% |

54–60% |

56–57% |

2.0–2.2% |

87–102 |

|

4 |

8–10% |

43–45% |

61–65% |

53–55% |

1.8–1.9% |

75–86 |

|

5 |

below 8% |

above 45% |

above 65% |

below 53% |

below 1.8% |

below 75 |

¹Digestible dry matter (DDM%) = 88.9 - 0.779 ADF (% of dry matter).

²Dry matter intake (DMI) = 120 ÷ forage NDF (% of dry matter).

³Relative feed value (RFV) calculated from DDM × DMI ÷ 1.29. Reference hay of 100 RFV contains 41% ADF and 53% NDF.

Obtaining Forage or Feed Laboratory Analysis

Mississippi feed and forage samples can be tested at the following:

Mississippi State University Chemical Lab

P.O. Box CR

Mississippi State, MS 39762

(662) 325-3428

Louisiana State University Southeast Research Station Forage Quality Laboratory

P.O. Drawer 569

Franklinton, LA 70438

(985) 839-3740

Private laboratories also offer analysis services. Fees, analysis options, and lab procedures may differ among labs. Follow any specific sampling and submission instructions the laboratory provides.

Forage samples submitted for nutrient quality analysis should be as fresh and representative as possible. This requires proper sampling technique. Use a forage probe with a sharp cutting device three-eighths to three-fourths of an inch in diameter to core bales instead of using grab samples. Sample at random from each hay lot. A hay lot should represent a single cutting, field, and cultivar (a quantity of no more than 200 bales).

Supply an adequate sample for analysis, at least half a pound of sample per lot. Combine at least 20 core samples from each hay lot into one sample for submission. For hay bales stored under cover, sample at a 45-degree angle from the top of the bale. For samples stored outside without cover, sample at a 90-degree angle from the top of the bale (on the side of the bale) because of possible weathering.

Feed samples submitted for nutrient quality analysis should be as representative as possible. It is important to grab sufficient samples. The term “grab” is used because that is essentially what is done. A handful pulled from within the pile of feed as far down toward the center of the pile as possible. Try to avoid the edges as environmental conditions may adversely skew the results of the test. Ten to 15 handfuls are recommended for bulk loads of feed. If sampling from a feed sack, assume the feed will be well mixed. However, settling may have occurred that may influence the results of the analysis. Therefore, three to five grab samples per sack are recommended.

For both forage and feed samples, be sure to identify each sample uniquely so results can be matched with the correct forage or feed source. Package samples securely, and ship promptly and properly to the chosen laboratory for analysis. If prompt shipping is not possible, then freeze samples for shipment later. Include a completed sample submission form and any necessary payments with each submission. Ship any perishable samples under refrigeration. If in doubt about sampling or shipping procedures, contact the laboratory that will analyze the samples or a local Extension office for instructions.

Summary

Forage and feed nutrient composition varies widely. A laboratory nutrient analysis is a valuable tool to determine if problems do exist in forage or feed production and how to best use these forages and feeds in a well-planned nutritional program. It is important to understand forage and feed analysis results in the context of animal requirements and the complete nutritional program. For more information on forage and feed analysis or livestock nutrition, contact your local Extension office.

References

Ball, D. M., C. S. Hoveland, & G. D. Lacefield. 2002. Southern Forages. 3rd ed. Potash and Phosphate Institute and Foundation for Agronomic Research. Norcross, GA.

National Research Council. 2000. Nutrient Requirements of Beef Cattle. 7th Revised Edition, 1996: Update 2000. National Academy Press. Washington, D.C.

Publication 2620 (POD-08-23)

Reviewed by Brandi Karisch, PhD, Associate Extension/Research Professor, Animal and Dairy Sciences. Written by Daniel Rivera, PhD, former Associate Research/Extension Professor, and Jane Parish, PhD, Professor and Head, North Mississippi Research and Extension Center.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.