P4155

Are Your Chicken Houses Ready for Winter?

To stay profitable, poultry producers should focus on consistent flock performance while lowering input costs. A well-sealed, properly insulated poultry house is one of the most effective tools for reaching these goals. Investing in house tightness and environmental control isn’t just about bird comfort; it’s about boosting operational efficiency and profitability all year long.

A tightly sealed poultry house prevents uncontrolled air leakage and allows your ventilation system to perform as intended. In summer, this makes your cool cell and tunnel ventilation systems work more efficiently, maintaining ideal temperatures and lowering heat stress on birds. In winter, it provides better ventilation control, helping to evenly distribute fresh air and mix cold incoming air with warmer air near the ceiling. This reduces cold drafts, lessens large temperature fluctuations, and keeps chicks comfortable, which is vital during brooding. Producers must capitalize on this phase since the birds grow more efficiently at younger ages. Mistakes made early in the flock cannot be corrected and will affect your overall performance.

Birds raised in well-insulated, tightly sealed, properly managed, and properly ventilated houses outperform those raised in drafty or poorly maintained environments. Producers can expect better feed conversion, more uniform growth, improved livability, and lower mortality. Stress is reduced, immune function improves, and overall bird health tends to improve. In short, tighter houses don’t just save you money—when properly managed, they will make you money.

Another key advantage of a tight house is litter quality. A house with improved environmental control makes it easier to remove excess moisture, which can lower microbial loads and ammonia levels in the litter. This leads to better paw health, fewer respiratory problems, and fewer condemnations at the processing plant.

Mastering ventilation can be difficult because the benefits aren’t always easily visible. Often, it is only after problems arise that ventilation deficiencies become evident. By then, it’s usually too late to overcome them.

Check Static Pressure

One way producers and service technicians can avoid problems before they arise is to understand and regularly check static pressure (SP), which is the key to a negative pressure ventilation system. SP measures the difference in air pressure between inside and outside the house when the fans run. An SP test is an indicator of how “tight” the house is and how well a producer can control the incoming air during ventilation. The ideal minimum SP test measurement for curtain-sided houses is 0.13–0.15 inches; for solid-sided houses, it’s 0.20–0.22 inches. SP test results that are much lower may indicate a loose house. Houses that meet these minimum requirements can better ensure that cool, incoming air enters at the correct speed and volume to reach the center of the house and mixes well with the warmer air near the ceiling.

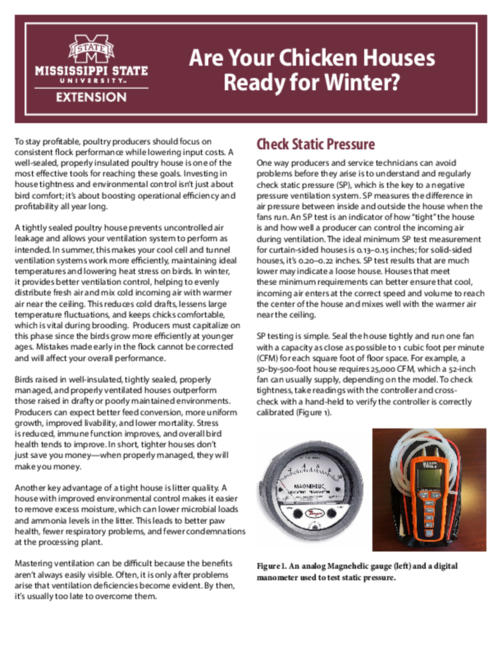

SP testing is simple. Seal the house tightly and run one fan with a capacity as close as possible to 1 cubic foot per minute (CFM) for each square foot of floor space. For example, a 50-by-500-foot house requires 25,000 CFM, which a 52-inch fan can usually supply, depending on the model. To check tightness, take readings with the controller and cross-check with a hand-held to verify the controller is correctly calibrated (Figure 1).

For someone new to checking SP, it’s a good idea first to measure the pressure, then open one door and watch the pressure change. The change in pressure caused by opening a door will provide a visual demonstration of the size of a given opening and how much it affects static pressure. It also demonstrates how many small holes and cracks must be identified and sealed to restore that pressure.

If your house isn’t reaching the target static pressure, it’s time to investigate. Visually inspect for cracks and holes in cool cell doors/curtains, end doors, vent box openings, ceiling tri-ply, and fan louvers that could allow air leakage, causing the static pressure to drop. Whenever you are checking ventilation and SP, always ensure you are using strong, well-maintained fans, or your readings may be inaccurate. It’s also wise to regularly inspect fans for dirty blades, worn belts, bad bearings, and failing pulleys, since a worn and dirty fan can reduce efficiency by more than 25 percent.

Smoke Test

A smoke test can also help identify hard-to-see leaks in curtains, around doors, or near footings and top plates where the sidewall meets the ceiling (Figure 2). Performing a smoke test is like checking SP, but introducing smoke outside the house lets the negative pressure draw it through cracks and holes. The smoke becomes visible from inside the house, allowing you to mark areas for repair. Commercial smoke generators can be purchased that produce colored smoke at a limited runtime. Alternatively, a propane-powered insect fogger with baby oil can generate thick, white smoke for extended periods of time. Keeping a fire extinguisher on hand is always recommended when performing a smoke test.

Insulation

Insulation is just as important, especially in the attic of the house. Over time, blown-in cellulose insulation tends to settle and become compacted, leading to areas without any insulation, particularly near the peak of the ceiling, where heat loss is most significant. Your ceiling might have initially had an insulation value of R-19 when built, but a decade’s worth of compaction can reduce it to R-10 or lower. Some areas near the peak may have significant uninsulated areas (Figure 3). This can significantly increase heating costs. A house with significant attic insulation settling could lose two to three times more heat through the ceiling than when it was new, resulting in much higher and unnecessary fuel usage.

Insulation of side and end walls is another key concern, especially in curtain-sided houses, which can use 15–25 percent more heating fuel during winter. If you have an older curtain-sided house or a retrofitted loose house lacking insulation and plan to stay in production for another 10–15 years, spray foam insulation could be an excellent solution.

Many older structures have three-quarter-inch lumber sidewalls with R-values as low as R-2 to R-3. Retrofitting with closed-cell spray foam is one of the most effective energy upgrades. It significantly increases insulation (around R-7 per inch), raising it to an R-10 to R-11, and most importantly seals most air leaks, greatly enhancing overall tightness. Closed-cell polyurethane spray-foamed solid sidewall retrofitting can boost static pressure by 10–15 points, reduce air leaks by 70–80 percent, and improve ventilation control.

The improvement in tightness and ventilation control benefits hot weather flocks as well through more efficient tunnel ventilation and evaporative cooling. Converting a curtain-sided house to a solid-wall structure offers more year-round benefits than most other structural upgrades. However, solid-side walled houses can also experience leaks and poor insulation. Over time, as the structure dries out, wood shrinks, and leaks can form where the wall meets the stem wall and the top plate, where the wall joins the ceiling.

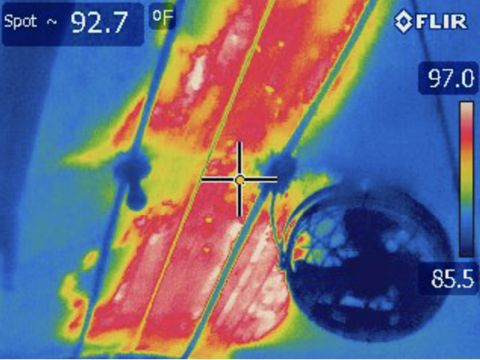

Wall insulation can also cause problems if improperly installed. Over time, deteriorated roll batts fall and settle inside the wall, leading to thermal leakage. Identifying areas with insufficient insulation can be tricky because it isn’t always easy to see. Tools like thermal cameras can help you find areas lacking insulation (Figure 4). These cameras clearly show hot and cold spots on walls, ceilings, and places that leak in winter and summer. It’s recommended that producers visually inspect their attics annually to check for insulation and roof truss issues.

Stir Fans

Don’t overlook the importance of stir fans. After tightening your house, using 18- to 24-inch basket fans in drop-ceiling structures to gently mix air helps reduce temperature differences. Stir fans improve comfort, lessen heat stratification, lower heater run times, encourage drier litter, and can provide fuel savings. Depending on controller options, stir fans can run continuously or cycle between minimum ventilation settings.

Grant Funding Opportunities

There are federal grant funding opportunities available to assist producers with energy upgrades. These grants cover insulation, equipment, controllers, lighting, doors, and ventilation improvements.

USDA’s REAP will reimburse 25–50 percent of energy upgrade costs; it is a quick process with nearly 100 percent approval. The REAP program is on hold but is expected to resume accepting applications after October 1, 2025.

NRCS’s EQIP program is a more extensive process with about a 40 percent approval rate, which cost-shares on a square foot basis. Cost share rates may vary by area, but it looks to reimburse approximately 75 percent of the total investment cost. The EQIP program does not list spray foam insulation as a covered practice, but it may be covered if part of a large project addressing energy efficiency in agricultural buildings. This may vary by region, so it is best to contact your local NRCS office for assistance.

Return on Investment

There are options if you find a loose house or poor insulation. You need to consider the house’s age, type of construction, and expected lifespan. Then, evaluate possible fixes and select the best return on investment (ROI). Each house may have different issues, so the payback period will also vary. On average, a conservative estimate for the return on energy upgrades could be 5–7 years based on savings alone. You may reduce this time significantly by including some potential performance improvements and grant assistance.

In a worst-case scenario, a typical older, leaky house with curtain walls, poor ceiling insulation, cool cell doors, and sidewall vent boxes, significant improvements can be achieved through some energy upgrades. Re-blowing attic insulation and spray foaming sidewalls in a 500-foot house may cost between $18,000 and $20,000, but it could save around $2,800 in heating costs per house for a winter flock in worst-case situations ($1.65 LP, curtain-sided/loose to solid/insulated). This could result in an ROI of about 3 years, which is considered good. If you factor in some performance gains and grant assistance, you could get your ROI down to as little as 1–1.5 years. (To maximize performance gains, it is crucial to learn how to properly manage the ventilation in your “new house” after energy upgrades. The house will respond differently, and subtle changes in ventilation can make huge differences. If you plan to upgrade your house, make sure you have a good rodent and beetle control program in place, as they can quickly damage the house structure and sabotage your renovations.

Summary

For producers, the main point is clear: a tighter house leads to healthier birds, lower input costs, and better profits. Regular inspections, static pressure tests, fan maintenance, and insulation upgrades should be included in your routine management and maintenance plan. Combine these improvements with available grant programs, and you can significantly boost performance and profitability with a solid return on investment.

Investing in sealing your poultry house isn’t just about saving on fuel; it’s about maximizing bird performance, increasing operational efficiency, and ensuring long-term sustainability for your farm. Tighten up that house; your birds and your wallet will thank you. If you need help evaluating your house’s insulation and static pressure, please contact your service rep or MSU Extension poultry specialist Jonathan Moon at jwm133@msstate.edu or (662) 325-3416.

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

Publication 4155 (POD-11-25)

By Jonathan Moon, Extension Instructor, Poultry Science, and Dennis Brothers, Associate Extension Professor, Agricultural Economics and Rural Sociology, Alabama Extension.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.

Authors

-

Extension Instructor

Extension Instructor- Poultry Science