P4153

High-Speed Soybean Planting in Mississippi

Timely planting is critical to maximize soybean yield. However, weather events and poorly drained soils in much of Mississippi limit planting during the optimal window. This puts pressure on producers because they need to cover a lot of ground in a short time. High-speed planting offers producers a new opportunity to cover more acres during the critical planting window.

Planting Window in Mississippi

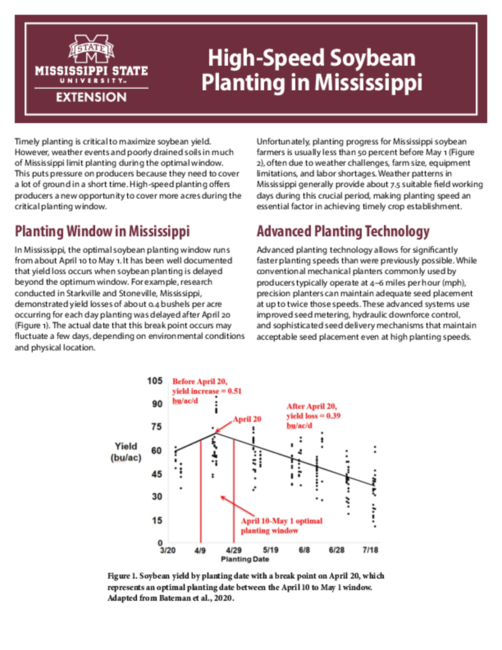

In Mississippi, the optimal soybean planting window runs from about April 10 to May 1. It has been well documented that yield loss occurs when soybean planting is delayed beyond the optimum window. For example, research conducted in Starkville and Stoneville, Mississippi, demonstrated yield losses of about 0.4 bushels per acre occurring for each day planting was delayed after April 20 (Figure 1). The actual date that this break point occurs may fluctuate a few days, depending on environmental conditions and physical location.

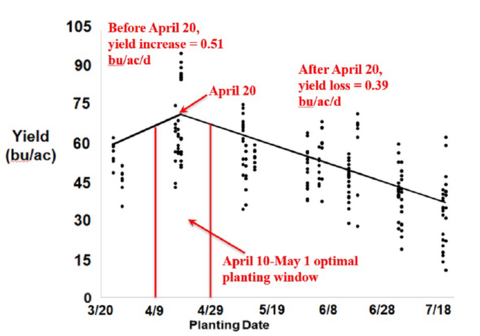

Unfortunately, planting progress for Mississippi soybean farmers is usually less than 50 percent before May 1 (Figure 2), often due to weather challenges, farm size, equipment limitations, and labor shortages. Weather patterns in Mississippi generally provide about 7.5 suitable field working days during this crucial period, making planting speed an essential factor in achieving timely crop establishment.

Advanced Planting Technology

Advanced planting technology allows for significantly faster planting speeds than were previously possible. While conventional mechanical planters commonly used by producers typically operate at 4–6 miles per hour (mph), precision planters can maintain adequate seed placement at up to twice those speeds. These advanced systems use improved seed metering, hydraulic downforce control, and sophisticated seed delivery mechanisms that maintain acceptable seed placement even at high planting speeds.

Planting Speed Affects Plant Population and Spacing

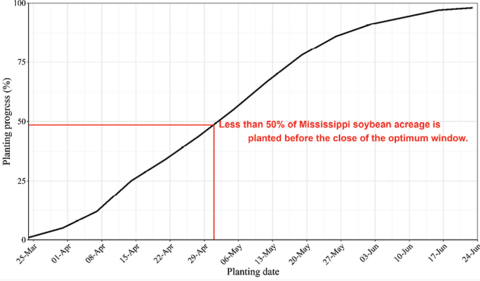

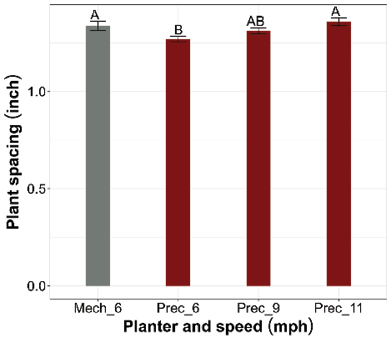

Mississippi State University research examined the effects of increased planting speeds on several key performance metrics across different sites in Mississippi. The study compared two planter systems: a precision planter and a mechanical planter (Figure 3). The precision planter (John Deere MaxEmerge 2 row units retrofitted with Ag Leader SureSpeed and SureForce) was tested at 6, 9, and 11 mph. The mechanical planter (John Deere 1700 ground-driven mechanical planter equipped with eSet meters) was tested at 6 mph to represent typical farmer practices. The seeding rate was 140,000 seeds per acre.

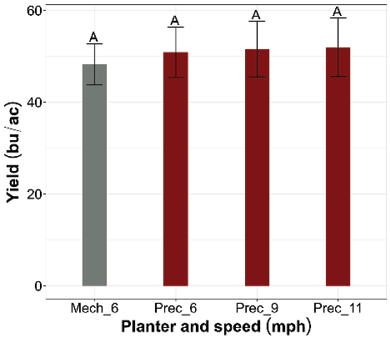

Although higher planting speeds generally lead to a reduction in final plant population (as well as increased variability in plant spacing), they did not translate into soybean yield losses (Figures 4 and 5). Soybeans demonstrate a remarkable ability to compensate for minor variations in spacing when populations remain within acceptable ranges (more than 80,000–100,000 plants per acre). At common seeding rates at or above 120,000 seeds per acre, plant stands consistently remained above yield-limiting thresholds, even at higher planting speeds.

Yield Performance

Most importantly, extensive field trials across Mississippi have shown no yield difference between soybean planted with a mechanical planter at 6 mph and those planted with a precision planter at speeds up to 11 mph (Figure 6). The consistency in yield has been demonstrated across various soil types and field conditions, suggesting broad applicability using advanced planting technologies for high-speed planting throughout the state.

Economic Implications

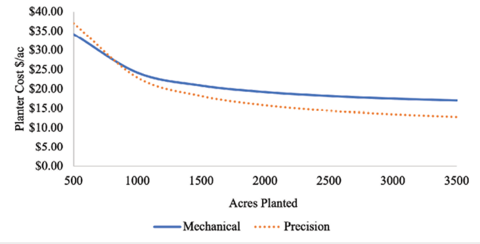

Mississippi State University research also examined the economic implications of the transition from traditional mechanical planters to precision planters. The analysis examined a 2,000-acre soybean operation comparing a 12-row 38-inch row-spacing mechanical planter operating at 5 mph versus a precision planter operating at 9 mph. The analysis demonstrated that, while precision planters required a higher initial investment ($150,000 compared to $106,000 for mechanical planters), they offered significant per-acre machinery cost savings and yield benefits that can offset the additional investment cost.

Machinery costs, which include both the operating and ownership costs of using the equipment, favored precision planters, with per-acre expenses of $15.81 compared to $19.20 for mechanical planters (a $3.39 per-acre reduction in costs; Table 1). This efficiency gain is primarily attributed to yield gains from more acres planted during optimal planting windows and reduced labor requirements due to faster planting speeds (9 mph versus 5 mph). There are other factors that impact these cost savings, including the number of acres planted. The more acres planted, the higher the cost savings to the precision planter. Conversely, the fewer acres planted, the more favorable the mechanical planter becomes (Figure 7). For more information, see MSU Extension Publication 3543 Farm Machinery Cost Calculations.

| Variable | Mechanical | Precision | Difference |

|---|---|---|---|

| Speed (mph) | 5 | 9 | |

| Days of planting | 23 | 13 | |

| Optimal start date | 9-Apr | 14-Apr | |

| Production (bu) | 139,469 | 141,814 | 2,345 |

| Revenue ($) | 1,429,555.04 | 1,453,591.50 | 24,036.46 |

| Costs per acre ($/ac) | 19.20 | 15.81 | (3.39) |

| Total costs ($) | 38,392.62 | 31,625.11 | (6,767.51) |

| Net returns ($) | 1,391,162.42 | 1,421,966.39 | 30,803.97 |

The yield implications are particularly noteworthy. By reducing the total planting window from 23 to 13 days on a 2,000-acre farm, precision planters enable farmers to plant closer to the optimal date (April 20). This timing advantage translates to an average yield increase of 1.2 bushels per acre. Assuming soybean prices at $10.25 per bushel, this yield improvement generates an additional $12.02 per acre in revenue.

The combined effect of reduced machinery costs per acre and increased yields results in a net return increase of $15.40 per acre. For a 2,000-acre soybean operation, the economic analysis indicates that the additional $44,000 investment in a precision planter would achieve payback within two years. However, it is important to evaluate adopting a precision planter using your own farm’s numbers to determine the potential benefits.

Management Considerations

Successful implementation of high-speed planting requires attention to field conditions and equipment performance. High-speed planting is more suitable for large fields with few obstructions. Producers should begin at lower speeds and gradually increase as conditions allow, regularly monitoring seed placement and making necessary adjustments to planter settings. Soil moisture, field preparation, residue levels, available horsepower and cooling systems, field size and shape, and terrain all influence optimal planting speed. Regular monitoring of seed depth and spacing is needed to ensure proper implementation of high-speed planting practices.

References

Bateman, N. R., Catchot, A. L., Gore, J., Cook, D. R., Musser, F. R., & Irby, J. T. (2020). Effects of planting date for soybean growth, development, and yield in the southern USA. Agronomy, 10(4), 596.

Heatherly, L., Bowers, G., Boethel, D., Baur, M., Rabb, J., Rupe, J., Typer, J., Way, M. O., & Ashlock, L. (1998). Early soybean production system handbook. Division of Agriculture, Forestry, and Veterinary Medicine, Mississippi State University.

Mills, E. B., Mulvaney, M. J., Lowe, J. W., & Olomitutu, O. E. (2024). Planting date: The need for speed. Southern Ag Today, 4(12.3).

Olomitutu, O. E., Mulvaney, M. J., Lowe, J. W., Bryant, C. J., Wallace, J., Harper, N., Larson, E. J., Shavers, G., Hilyer, T. & Dhillon, J. (2024). Soybean response to high‐speed planting in Mississippi. Agronomy Journal, 116(6), 2817–2826.

U.S. Department of Agriculture National Agricultural Statistics Service (USDA NASS). (2024). Quick stats [Data set].

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

Publication 4153 (POD-11-25)

By Oluwaseyi E. Olomitutu, Graduate Research Assistant, Plant and Soil Sciences; Jagman Dhillon, PhD, Associate Professor, Plant and Soil Sciences; J. Wes Lowe, PhD, Assistant Professor, Agricultural and Biological Engineering; Brian Mills, PhD, Associate Professor, Agricultural Economics; Corey J. Bryant, PhD, Assistant Professor, Delta Research and Extension Center; Erick J. Larson, PhD, Extension/Research Professor, Plant and Soil Sciences; Jialin Zhang, PhD, Assistant Professor, Mathematics and Statistics; John Wallace, Research Associate II, Plant and Soil Sciences; Justin Calhoun, PhD, Assistant Professor, Plant and Soil Sciences; and Michael J. Mulvaney, PhD, Associate Professor and Endowed Chair, Plant and Soil Sciences.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.

Authors

-

Associate Professor

Associate Professor- Agricultural Economics

-

Assistant Professor

Assistant Professor- Delta Research and Extension Center

-

Extension/Research Professor

Extension/Research Professor- Plant and Soil Sciences

-

Assistant Professor

Assistant Professor- Ag & Bio Engineering

-

Assistant Professor

Assistant Professor- Plant and Soil Sciences

-

Assoc Prof & Endowed Chair

Assoc Prof & Endowed Chair- Plant and Soil Sciences